描述

产品简要说明

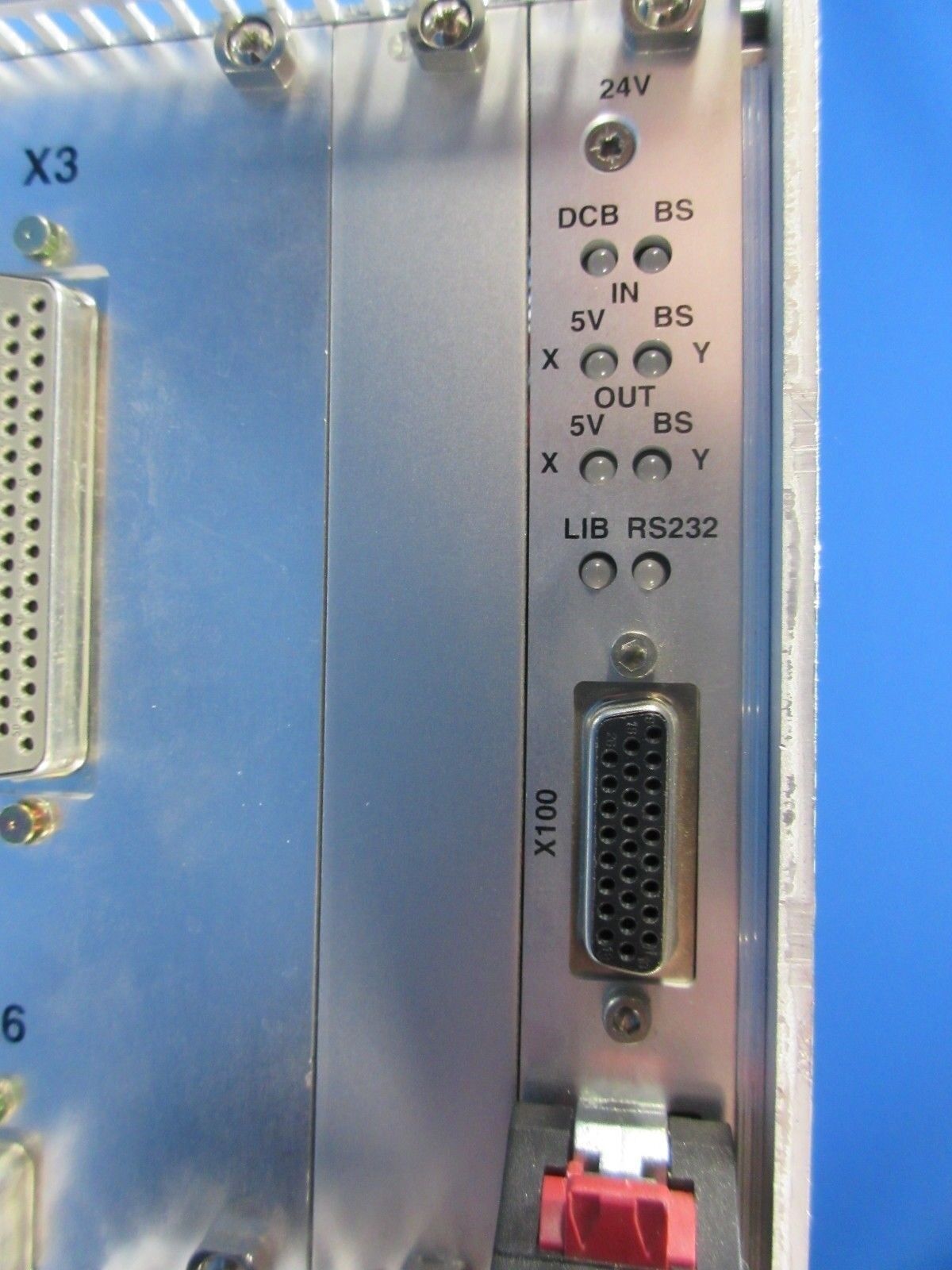

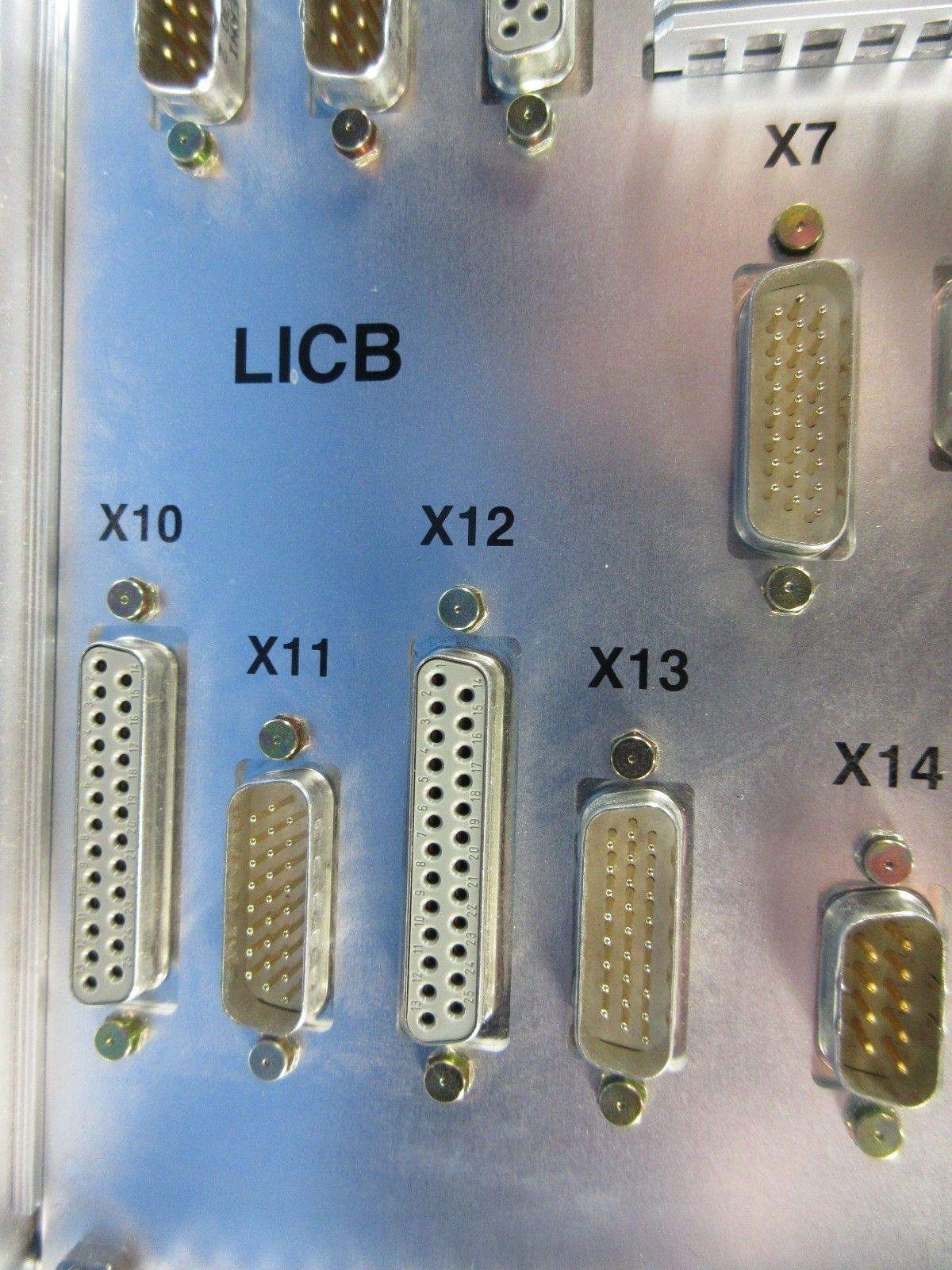

ASML 4022.470.5381是ASML为先进半导体制造设备设计的高精度控制模块,属于光刻机核心逻辑接口板(LICB)系列。其核心功能包括:

多轴协同控制:支持6自由度机械运动同步,定位精度≤0.001mm,动态响应时间≤2ms。

实时数据处理:集成FPGA芯片,数据采样率≥1MHz,指令执行延迟≤0.5μs。

环境自适应:兼容真空环境(≤1e-12 Pa)及超低温(-40℃~120℃),抗电磁干扰能力≥100dB。

产品详细说明

1.硬件架构设计

模块化接口:

多协议兼容:支持EtherCAT、CANopen及定制化工业协议,接口带宽≥1Gbps。

电源冗余:双路24V/48V供电,断电切换时间≤10ms,过载保护阈值≥200%。

高密度集成:

芯片布局:采用7nm制程FPGA+多核ARM处理器,算力≥50 GFLOPS。

散热设计:液冷循环系统,热阻≤0.1℃/W,温度波动≤0.01℃。

2.智能控制算法

动态补偿模型:

机械形变预测:基于有限元分析的实时形变补偿,补偿效率≥99.9%。

振动抑制:主动阻尼控制,振动幅值≤0.01μm(10-1000Hz频段)。

自诊断系统:

故障定位:通过机器学习识别300+种异常模式,诊断准确率≥98%。

寿命预测:关键部件(如电机、传感器)剩余寿命预测误差≤5%。

3.行业应用优化

半导体制造:

晶圆定位误差≤0.005mm,曝光场均匀性≥99.9%。

与EUV光源联动,光强波动控制≤0.1%。

精密机械:

支持纳米级3D打印,层间错位≤0.02μm。

适用于原子力显微镜(AFM)的纳米级扫描控制。

技术规格:ASML 4022.470.5381

参数项规格描述

定位精度≤0.001mm(3σ)

数据处理能力1MHz采样率,0.5μs指令延迟

环境适应性温度:-40℃~120℃;真空度:≤1e-12 Pa

抗干扰能力电磁屏蔽≥100dB,机械振动抑制≥99.5%

Product brief description

ASML 4022.470.5381 is a high-precision control module designed by ASML for advanced semiconductor manufacturing equipment.It belongs to the core logic interface board(LICB)series of lithography machines.Its core functions include:

Multi-axis collaborative control:supports 6-degree of freedom mechanical motion synchronization,positioning accuracy≤0.001mm,and dynamic response time≤2ms.

Real-time data processing:Integrated FPGA chip,data sampling rate≥1MHz,instruction execution delay≤0.5μs.

Environmental adaptability:compatible with vacuum environment(≤1e-12 Pa)and ultra-low temperature(-40℃~120℃),with anti-electromagnetic interference capability≥100dB.

Product details

1.Hardware architecture design

Modular interface:

Multi-protocol compatibility:supports EtherCAT,CANopen and customized industrial protocols,with interface bandwidth≥1Gbps.

Power supply redundancy:dual-channel 24V/48V power supply,power off switching time≤10ms,overload protection threshold≥200%.

High density integration:

Chip layout:adopts 7nm process FPGA+multi-core ARM processor,with computing power≥50 GFLOPS.

Heat dissipation design:liquid-cooled circulation system,thermal resistance≤0.1℃/W,temperature fluctuations≤0.01℃.

2.Intelligent control algorithm

Dynamic compensation model:

Mechanical deformation prediction:Real-time deformation compensation based on finite element analysis,compensation efficiency≥99.9%.

Vibration suppression:Active damping control,vibration amplitude≤0.01μm(10-1000Hz frequency band).

Self-diagnosis system:

Fault location:300+abnormal patterns are identified through machine learning,and the diagnostic accuracy is≥98%.

Life expectation:The remaining life expectation error of key components(such as motors,sensors)is≤5%.

3.Industry application optimization

Semiconductor manufacturing:

The wafer positioning error is≤0.005mm,and the exposure field uniformity is≥99.9%.

Linked with the EUV light source,the light intensity fluctuation control is≤0.1%.

Precision machinery:

Supports nano-level 3D printing,with interlayer dislocation≤0.02μm.

Nanoscale scanning control for atomic force microscopy(AFM).

Technical specifications:ASML 4022.470.5381

Parameters Specification Description

Positioning accuracy≤0.001mm(3σ)

Data processing capability:1MHz sampling rate,0.5μs instruction delay

Environmental adaptability Temperature:-40℃~120℃;vacuum:≤1e-12 Pa

Anti-interference ability:electromagnetic shielding≥100dB,mechanical vibration suppression≥99.5%