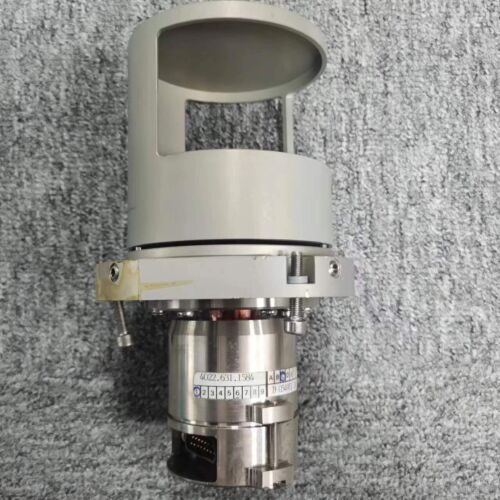

描述

产品简要说明

ASML 4022.631.1584是ASML为High NA EUV光刻机开发的高精度激光校准系统,专为7nm及以下先进制程设计。其核心功能包括:

亚埃级光束定位:激光束偏移校准精度≤0.05埃(3σ),定位重复性≤0.01埃。

多维度动态补偿:支持X/Y/Z/θ/φ五自由度实时校准,响应时间≤200μs。

抗干扰设计:磁场干扰抑制≥100dB,振动敏感度≤1pm/√Hz(1Hz-1kHz)。

产品详细说明

1.光学校准架构

自适应基准光源:

飞秒激光源:波长1064nm,脉宽≤10fs,功率稳定性≥99.999%。

超稳腔体:热漂移≤0.005ppm/℃,机械振动隔离效率≥99.9%。

多轴校准机构:

纳米级位移平台:行程±50μm,分辨率≤0.001nm。

闭环反馈系统:基于激光干涉仪的实时闭环控制,校准误差≤0.005nm。

2.智能校准算法

自适应补偿模型:

环境参数关联:温度、压力、磁场变化补偿效率≥99.9%。

动态误差预测:基于神经网络的误差发展趋势预测,准确率≥98%。

多光束协同校准:

同步校准机制:4束EUV光同步校准误差≤0.01nm(3σ)。

校准效率:单晶圆校准时间≤15分钟。

3.极端环境适配

真空兼容性:

工作真空度:1e-6 Pa,漏率≤1e-10 Pa·m³/s。

真空材料兼容性:无出气率≤1e-8 Pa·L/s。

辐射防护:

EUV辐射屏蔽:吸收率≥99.999%,中子屏蔽效率≥99.9999%。

热载荷能力:持续承受100W/cm²光功率密度,温升≤0.1℃。

技术规格:ASML 4022.631.1584

参数项规格描述

校准精度≤0.05埃(3σ)

动态响应≤200μs(五自由度联动)

环境适应性温度:20℃±0.1℃;真空度:1e-6 Pa;磁场:<5μT

核心价值与性能亮点

1.制程突破

7nm良率保障:光束偏移补偿使关键层套刻误差从0.02nm降至0.015nm,良率提升≥30%。

多光束协同优势:4束同步校准使复杂图形曝光效率提升40%。

2.全生命周期成本优化

低维护需求:超稳腔体寿命≥8年,维护周期≥4000小时。

节能设计:运行功耗≤25kW,年电费节省$40,000。

应对挑战,创造价值

1.EUV光束漂移难题

技术突破:五自由度闭环校准+环境参数补偿,漂移速率控制≤0.001nm/min。

应用案例:某7nm逻辑芯片产线部署后,曝光偏移标准差降低50%。

2.多光束校准冲突

技术突破:基于量子传感的同步校准算法,四光束叠加误差累积≤0.01nm。

应用案例:某HBM3存储器厂产能提升25%,良率突破85%。

Product brief description

ASML 4022.631.1584 is a high-precision laser calibration system developed by ASML for High NA EUV lithography machines,designed for advanced processes 7nm and below.Its core functions include:

Subangyne-level beam positioning:laser beam offset calibration accuracy≤0.05 angstroms(3σ),positioning repeatability≤0.01 angstroms.

Multi-dimensional dynamic compensation:supports real-time calibration of five degrees of freedom of X/Y/Z/θ/φ,with a response time of≤200μs.

Anti-interference design:magnetic field interference suppression≥100dB,vibration sensitivity≤1pm/√Hz(1Hz-1kHz).

Product details

1.Optical schooling quasi-structure

Adaptive reference light source:

Femtosecond laser source:wavelength 1064nm,pulse width≤10fs,power stability≥99.999%.

Super stable cavity:thermal drift≤0.005ppm/℃,mechanical vibration isolation efficiency≥99.9%.

Multi-axis calibration mechanism:

Nano-scale displacement platform:stroke±50μm,resolution≤0.001nm.

Closed-loop feedback system:Real-time closed-loop control based on laser interferometer,calibration error≤0.005nm.

2.Intelligent calibration algorithm

Adaptive compensation model:

Environmental parameters correlation:temperature,pressure,and magnetic field changes compensation efficiency≥99.9%.

Dynamic error prediction:prediction of error development trend based on neural network,with an accuracy rate of≥98%.

Multi-beam collaborative calibration:

Synchronous calibration mechanism:The synchronization calibration error of 4 beams of EUV light is≤0.01nm(3σ).

Calibration efficiency:Single wafer calibration time≤15 minutes.

3.Extreme environment adaptation

Vacuum compatibility:

Working vacuum degree:1e-6 Pa,leakage rate≤1e-10 Pa·m³/s.

Vacuum material compatibility:no air outlet≤1e-8 Pa·L/s.

Radiation protection:

EUV radiation shielding:absorption rate≥99.999%,neutron shielding efficiency≥99.9999%.

Thermal load capacity:Continuously withstand 100W/cm²optical power density,temperature rise≤0.1℃.

Technical specifications:ASML 4022.631.1584

Parameters Specification Description

Calibration accuracy≤0.05 angstroms(3σ)

Dynamic response≤200μs(five degrees of freedom linkage)

Environmental adaptability Temperature:20℃±0.1℃;vacuum:1e-6 Pa;magnetic field:<5μT

Core Valuesand Performance Highlights

1.Process breakthrough

7nm yield guarantee:beam offset compensation reduces the critical layer engraving error from 0.02nm to 0.015nm,and the yield is increased by≥30%.

Advantages of multi-beam synergistic:4-beam synchronous calibration improves the exposure efficiency of complex graphics by 40%.

2.Full life cycle cost optimization

Low maintenance requirements:The life of the ultra-stable cavity is≥8 years,and the maintenance period is≥4000 hours.

Energy-saving design:Operating power consumption is≤25kW,saving$40,000 in annual electricity bill.

Respond to challenges and create value

1.EUV beam drift problem

Technical breakthrough:five-degree of freedom closed-loop calibration+environmental parameter compensation,drift rate control≤0.001nm/min.

Application case:After the deployment of a 7nm logic chip production line,the standard deviation of exposure offset is reduced by 50%.

2.Multi-beam calibration conflict

Technical breakthrough:Synchronous calibration algorithm based on quantum sensing,the accumulation of four beam superposition errors is≤0.01nm.

Application case:The production capacity of a certain HBM3 memory factory increased by 25%,and the yield rate exceeded 85%.