描述

产品简要说明

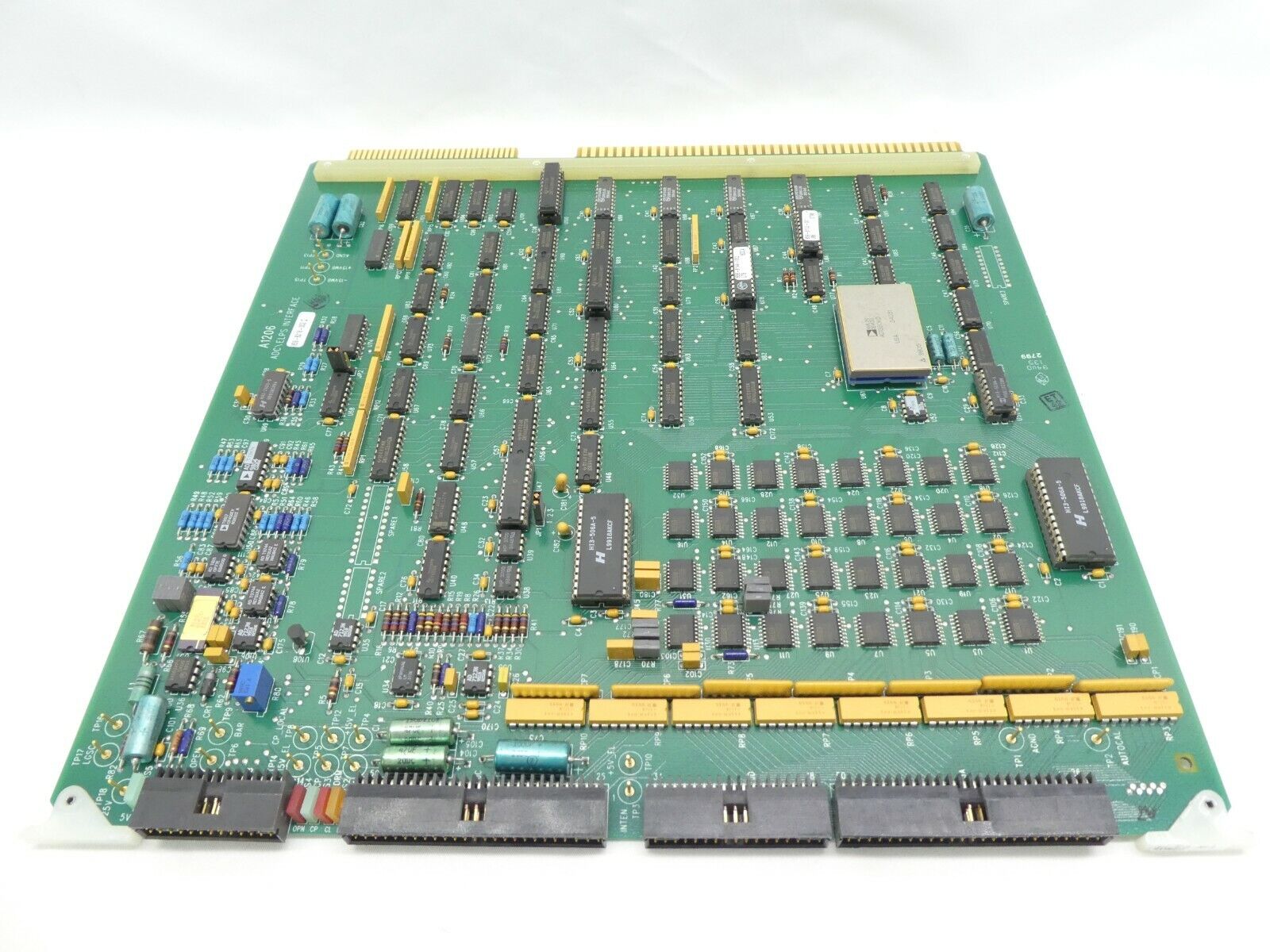

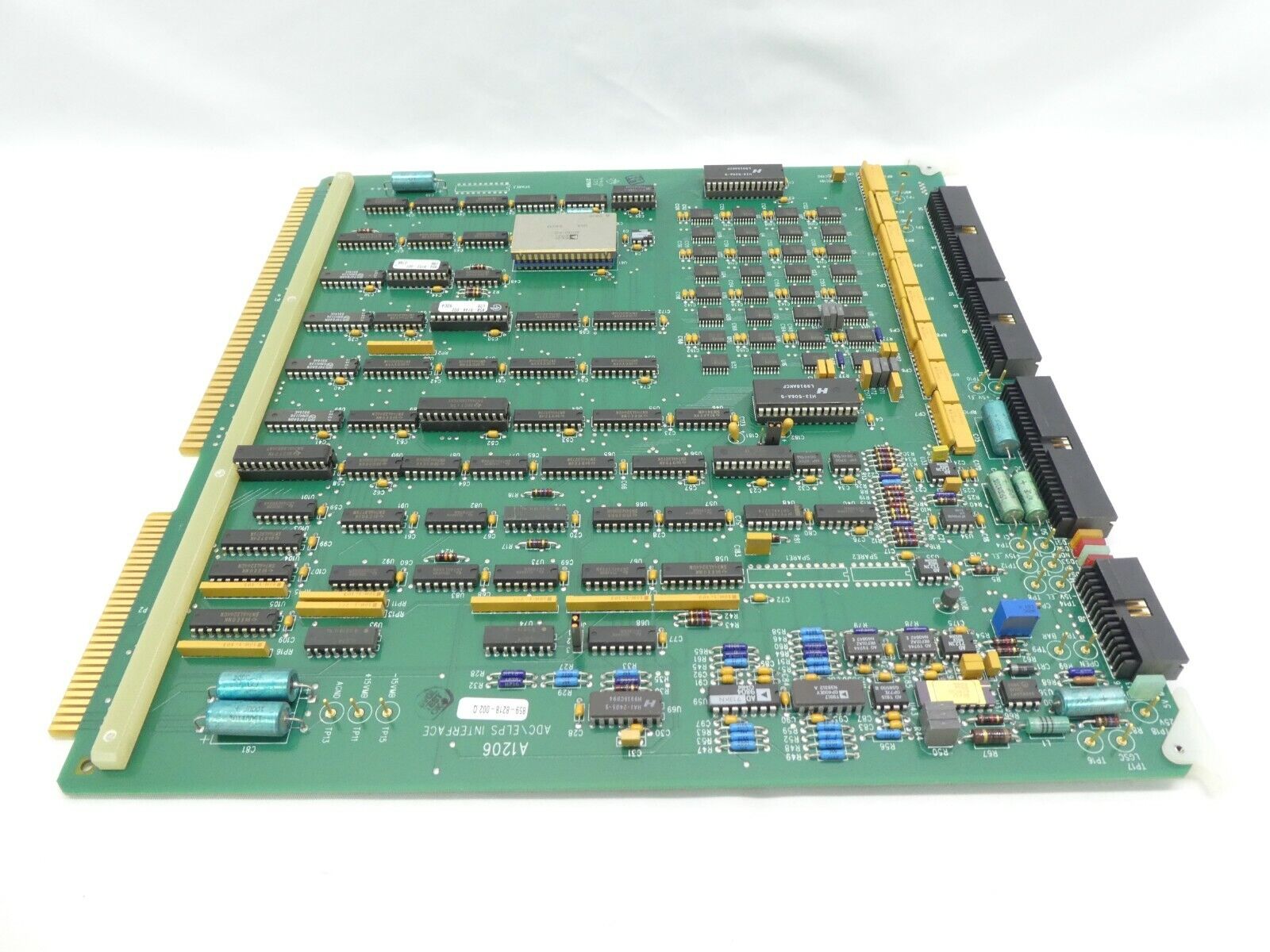

ASML 859-8218-002Q是ASML专为极紫外(EUV)光刻机设计的高频多层印刷电路板(PCB),核心特性包括:

12层HDI叠层结构:支持10GHz信号传输,插入损耗≤0.2dB。

纳米级运动控制适配:兼容High-NA EUV光刻机的双工件台同步定位需求。

洁净室级可靠性:通过Class 1洁净室认证,抗静电等级ESD 8kV。

产品详细说明

1.技术架构与核心功能

高频信号传输:

采用聚酰亚胺(PI)与低损耗陶瓷复合基材,支持10GHz高频信号传输,插入损耗≤0.2dB(1GHz~10GHz)。

集成阻抗匹配网络与滤波器,信号完整性(S参数)误差<±1.5%。

运动控制适配:

支持双工件台(晶圆台/掩模台)的纳米级同步定位控制,时序精度达±50ps。

集成运动补偿算法接口,兼容ASML的Real-time Positioning(RTP)系统。

抗干扰设计:

多层屏蔽层(含铜箔与氮化钛涂层),电磁屏蔽效能达60dB(100MHz~1GHz)。

采用差分信号传输技术,共模抑制比(CMRR)>80dB。

2.性能突破

制程兼容性:

支持3nm及以下逻辑芯片与2nm存储芯片的曝光控制需求。

环境适应性:

温度范围-40℃~125℃,热膨胀系数(CTE)与光刻机基材匹配(50ppm/℃)。

抗湿性等级IP68(水下1米浸泡24小时)。

能效优化:

采用动态电源管理技术,待机功耗≤1W,整体能效提升40%。

技术规格:ASML 859-8218-002Q

参数项规格描述

层数12层HDI叠层

基材类型聚酰亚胺(PI)与陶瓷复合材料

信号传输频率10GHz(插入损耗≤0.2dB)

尺寸范围定制化(最小尺寸:60mm×60mm)

工作温度-40℃~100℃

抗静电等级ESD 8kV(人体模型)

功耗≤12W(典型值)

Product brief description

ASML 859-8218-002Q is a high-frequency multi-layer printed circuit board(PCB)designed by ASML for extreme ultraviolet(EUV)lithography machines.The core features include:

12-layer HDI stacked structure:supports 10GHz signal transmission,insertion loss≤0.2dB.

Nano-level motion control adaptation:compatible with the synchronous positioning requirements of dual workpiece tables of High-NA EUV lithography machines.

Clean room-level reliability:passed Class 1 clean room certification,antistatic grade ESD 8kV.

Product details

1.Technical architecture and core functions

High frequency signal transmission:

Polyimide(PI)and low-loss ceramic composite substrate are used to support 10GHz high-frequency signal transmission,and the insertion loss is≤0.2dB(1GHz~10GHz).

Integrated impedance matching network and filter,signal integrity(S parameter)error<±1.5%.

Motion control adaptation:

Supports nano-level synchronous positioning control of dual workpiece tables(wafer tables/mask tables),with timing accuracy up to±50ps.

Integrated motion compensation algorithm interface,compatible with ASML’s Real-time Positioning(RTP)system.

Anti-interference design:

Multi-layer shielding layer(including copper foil and titanium nitride coating),electromagnetic shielding effect reaches 60dB(100MHz~1GHz).

Differential signal transmission technology is adopted,common mode rejection ratio(CMRR)>80dB.

2.Performance breakthrough

Process compatibility:

Supports exposure control requirements for logic chips below 3nm and 2nm memory chips.

Environmental adaptability:

The temperature range is-40℃~125℃,and the coefficient of thermal expansion(CTE)matches the lithography machine substrate(50ppm/℃).

Wet resistance grade IP68(soak 1 meter under water for 24 hours).

Energy efficiency optimization:

Dynamic power management technology is adopted,standby power consumption is≤1W,and the overall energy efficiency is improved by 40%.

Technical specifications:ASML 859-8218-002Q

Parameter specification description

12 layers HDI stack

Base material type polyimide(PI)and ceramic composite materials

Signal transmission frequency 10GHz(insert loss≤0.2dB)

Customized size range(minimum size:60mm×60mm)

Working temperature-40℃~100℃

Antistatic grade ESD 8kV(manner model)

Power consumption≤12W(typical)