描述

产品简要说明

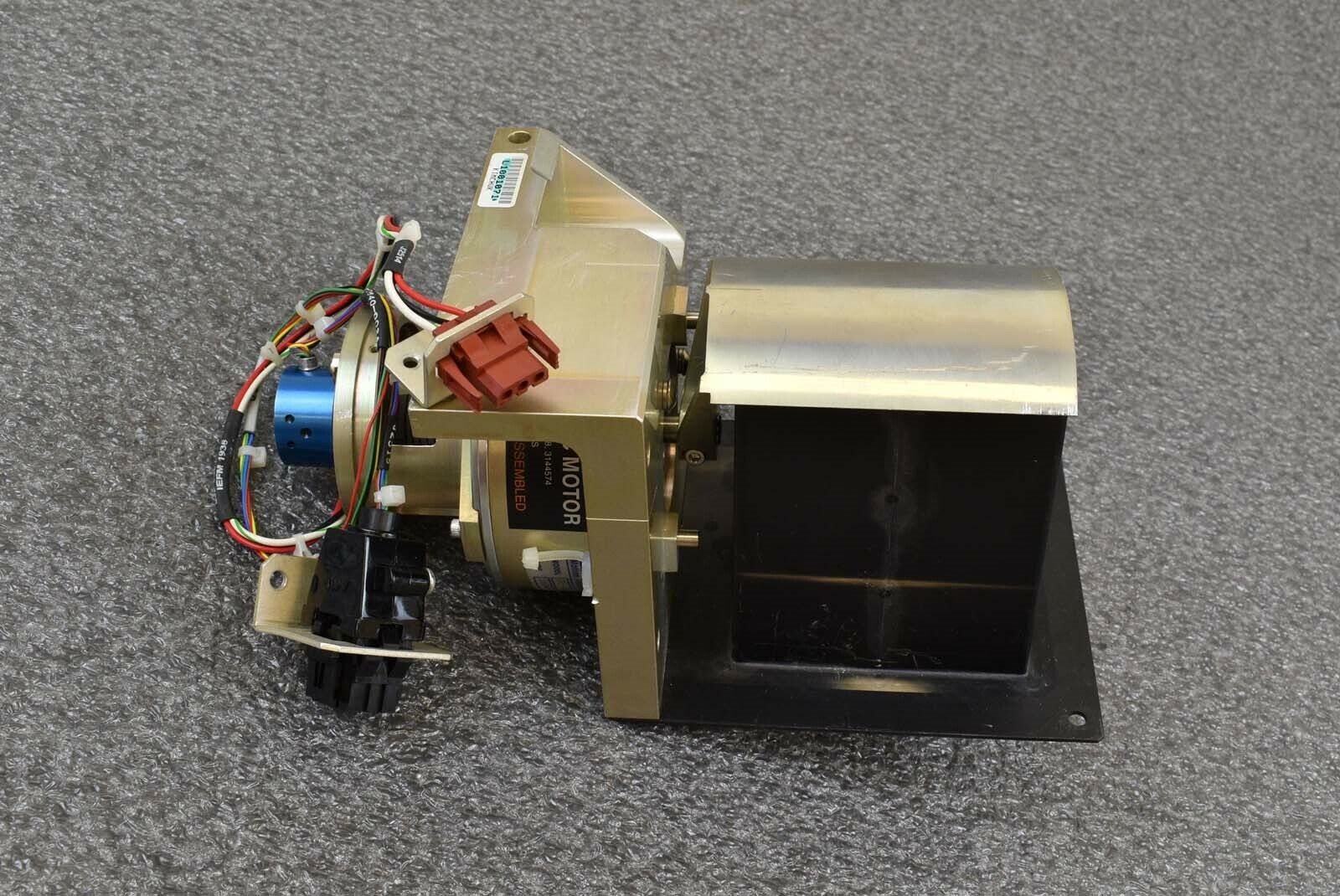

ASML 879-0262-002是ASML专为光刻机设计的高精度快门互锁组件,核心特性包括:

亚微米级机械定位:采用磁悬浮驱动与压电陶瓷补偿技术,定位误差≤0.1μm。

多级安全互锁:支持机械、电气、软件三重冗余防护,误操作响应时间<1ms。

洁净室级可靠性:通过Class 1洁净室认证,抗静电等级ESD 8kV。

产品详细说明

1.技术架构与核心功能

机械定位系统:

由超精密滚珠丝杠(螺距误差≤0.5μm)与谐波减速器组成,实现亚微米级重复定位精度。

集成磁编码器(分辨率1nm)与闭环控制算法,动态响应时间<500μs。

互锁机制设计:

机械互锁:采用钢球卡扣结构,断电状态下仍保持物理锁定状态。

电气互锁:通过霍尔传感器与安全继电器实现通断电状态实时监测。

软件互锁:与光刻机控制系统的安全协议(如SECS/GEM)深度集成,支持紧急停止指令优先级处理。

环境适应性:

真空封装设计,内部气压<1e-3 mbar,减少空气湍流对定位精度的影响。

钛合金外壳与陶瓷轴承,热膨胀系数(CTE)匹配光刻机基座(1.2ppm/℃)。

2.性能突破

抗干扰能力:

屏蔽层采用铜-钛合金复合结构,电磁屏蔽效能达60dB(1MHz~1GHz)。

能效优化:

动态功耗管理技术,待机功耗≤5W,运行功耗≤25W。

长寿命设计:

通过加速老化测试,预计使用寿命≥10年(24/7运行)。

技术规格:ASML 879-0262-002

参数项规格描述

定位精度≤0.1μm(RMS)

互锁响应时间<1ms(机械+电气双重触发)

工作温度20℃±0.5℃(恒温控制)

真空环境内部气压<1e-3 mbar

驱动方式磁悬浮+压电陶瓷复合驱动

功耗≤25W(运行模式)

核心价值与性能亮点

1.极端环境适应性

真空环境稳定性:采用无油润滑磁悬浮轴承,避免油污污染光学元件。

低温恒温设计:内置珀尔帖温控模块,温度波动≤0.05℃,确保机械部件形变<0.05μm。

2.多场景扩展性

跨代兼容性:适配ASML NXE 3600D及后续High-NA EUV光刻机。

工业互联网集成:预留OPC UA接口,支持与MES系统实时数据交互。

3.全生命周期成本优化

自清洁功能:内置离子风清洁系统,减少人工维护频率。

模块化更换:快门组件与驱动单元可独立更换,维修成本降低50%。

Product brief description

ASML 879-0262-002 is a high-precision shutter interlock assembly designed by ASML for lithography machines.The core features include:

Submicron-level mechanical positioning:Magnetic levitation drive and piezoelectric ceramic compensation technology are used,and the positioning error is≤0.1μm.

Multi-stage safety interlocking:supports triple redundant protection for mechanical,electrical and software,and the response time for error operation is<1ms.

Clean room-level reliability:passed Class 1 clean room certification,antistatic grade ESD 8kV.

Product details

1.Technical architecture and core functions

Mechanical positioning system:

It consists of an ultra-precision ball screw(pitch error≤0.5μm)and a harmonic reducer to achieve submicron-level repeat positioning accuracy.

Integrated magnetic encoder(resolution 1nm)and closed-loop control algorithm,dynamic response time<500μs.

Interlocking mechanism design:

Mechanical interlocking:adopts a steel ball snap structure,and remains physically locked when power is off.

Electrical interlock:Real-time monitoring of on-off status through Hall sensors and safety relays.

Software interlock:In-depth integration with the safety protocols of lithography machine control systems(such as SECS/GEM)to support emergency stop instruction priority processing.

Environmental adaptability:

Vacuum package design,internal air pressure<1e-3 mbar,reduces the impact of air turbulence on positioning accuracy.

Titanium alloy shell and ceramic bearing,thermal expansion coefficient(CTE)match the base of the lithography machine(1.2ppm/℃).

2.Performance breakthrough

Anti-interference ability:

The shielding layer adopts a copper-titanium alloy composite structure,and the electromagnetic shielding effect is 60dB(1MHz~1GHz).

Energy efficiency optimization:

Dynamic power consumption management technology,standby power consumption≤5W,and running power consumption≤25W.

Long life design:

Through accelerated aging test,the estimated service life is≥10 years(operating 24/7).

Technical Specifications:ASML 879-0262-002

Parameters Specification Description

Positioning accuracy≤0.1μm(RMS)

Interlock response time<1ms(mechanical+electrical double trigger)

Working temperature:20℃±0.5℃(constant temperature control)

Vacuum environment Internal air pressure<1e-3 mbar

Drive mode Magnetic levitation+piezoelectric ceramic composite drive

Power consumption≤25W(operating mode)

Core Valuesand Performance Highlights

1.Extreme environmental adaptability

Vacuum environment stability:oil-free lubricated magnetic levitation bearings are used to avoid oil pollution from contaminating optical components.

Low temperature constant temperature design:built-in Peltier temperature control module,temperature fluctuations≤0.05℃,ensuring deformation of mechanical components<0.05μm.

2.Multi-scene scalability

Cross-generation compatibility:adapted to ASML NXE 3600D and subsequent High-NA EUV lithography machines.

Industrial Internet integration:reserves OPC UA interface and supports real-time data interaction with MES systems.

3.Full life cycle cost optimization

Self-cleaning function:built-in ion air cleaning system to reduce the frequency of manual maintenance.

Modular replacement:The shutter assembly and drive unit can be replaced independently,reducing maintenance costs by 50%.