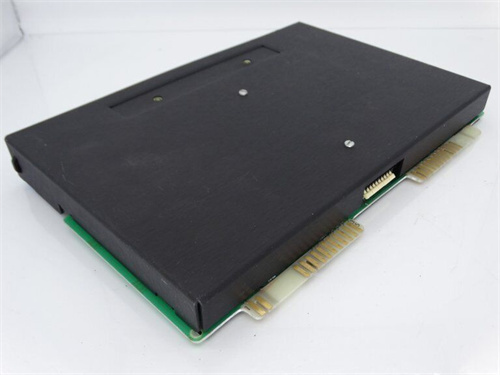

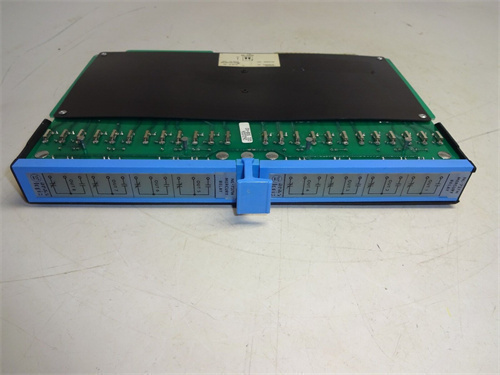

描述

ASYST1380-101545-11是一款工业级智能控制模块,专为复杂自动化系统设计,支持多协议通信与高精度数据处理。以下是其核心功能、技术参数及应用场景的综合概述:

一、核心功能与技术参数

模块规格

-型号:ASYST1380-101545-11

-结构形式:分布式安装,支持导轨或面板固定

-工作电压:24V DC(±10%)

-处理能力:主频16MHz,支持多任务并行处理

-接口类型:

-模拟输入:8路0-10V/4-20mA

-数字输入/输出:16DI/16DO(可编程)

-通信接口:RS485、Modbus TCP/IP、CAN总线

核心功能

-多协议兼容:支持Modbus RTU、Profinet、EtherCAT等工业协议,可无缝集成至主流控制系统。

-高精度数据采集:模拟输入分辨率16位,采样速率1kHz,适用于压力、温度等关键参数监测。

-逻辑控制与算法:内置PLC逻辑引擎,支持自定义算法编写(如PID控制、模糊逻辑),满足复杂工艺需求。

二、应用场景

工业自动化

-机械臂协同控制:通过多路模拟信号实时调整机械臂位置与力度,应用于精密装配场景。

-能源管理系统:监测光伏逆变器电压/电流,动态优化发电效率。

轨道交通

-信号灯联动:基于CAN总线协议实现列车进站时的信号灯同步控制。

-车辆健康监测:采集电机温度、转速数据,预测性维护减少停运风险。

医疗设备

-生命体征监测:处理心电、血压等模拟信号,支持医疗设备与医院系统的数据交互。

三、技术优势

高可靠性

-宽温设计:-40℃至+85℃环境温度稳定运行

-冗余供电:支持双电源输入(24V DC),单点故障时无缝切换

-抗干扰能力:通过EMC四级认证,适用于强电磁干扰环境

灵活扩展性

-模块化接口:支持扩展IO模块(如加速度传感器、流量计)

-云端集成:内置MQTT协议,可直接上传数据至工业物联网平台。

四、行业适用性

制造业:注塑机、CNC机床的闭环控制

电力系统:变电站开关柜状态监测

智慧城市:智能路灯、安防摄像头集群控制

ASYST1380-101545-11 is an industrial-grade intelligent control module designed for complex automation systems,supporting multi-protocol communication and high-precision data processing.The following is a comprehensive overview of its core functions,technical parameters and application scenarios:

I.Core functions and technical parameters

Module specifications

-Model:ASYST1380-101545-11

-Structure:distributed installation,support rail or panel fixation

-Working voltage:24V DC(±10%)

-Processing power:main frequency 16MHz,support multi-task parallel processing

-Interface type:

-Analog input:8 channels 0-10V/4-20mA

-Digital input/output:16DI/16DO(programmable)

-Communication interface:RS485,Modbus TCP/IP,CAN bus

Core functions

-Multi-protocol compatibility:supports Modbus RTU,Profinet,EtherCAT and other industrial protocols,and can be seamlessly integrated into mainstream control systems.

-High-precision data acquisition:analog input resolution is 16 bits,sampling rate is 1kHz,suitable for monitoring key parameters such as pressure and temperature.

-Logic control and algorithm:built-in PLC logic engine,supports custom algorithm writing(such as PID control,fuzzy logic),to meet complex process requirements.

2.Application scenarios

Industrial automation

-Robot arm collaborative control:real-time adjustment of robot arm position and strength through multi-channel analog signals,applied to precision assembly scenarios.

-Energy management system:monitor photovoltaic inverter voltage/current,dynamically optimize power generation efficiency.

Railway transportation

-Signal light linkage:based on CAN bus protocol,synchronized control of signal lights when trains enter the station is realized.

-Vehicle health monitoring:collect motor temperature and speed data,predictive maintenance to reduce the risk of downtime.

Medical equipment

-Vital signs monitoring:process analog signals such as ECG and blood pressure,and support data interaction between medical equipment and hospital systems.

3.Technical advantages

High reliability

-Wide temperature design:Stable operation in-40℃to+85℃ambient temperature

-Redundant power supply:Supports dual power input(24V DC),seamless switching in case of single point failure

-Anti-interference ability:Passed EMC Level 4 certification,suitable for strong electromagnetic interference environment

Flexible scalability

-Modular interface:Supports expansion of IO modules(such as accelerometers,flow meters)

-Cloud integration:Built-in MQTT protocol,can directly upload data to the industrial Internet of Things platform.

4.Industry applicability

Manufacturing:Closed-loop control of injection molding machines and CNC machine tools

Power system:Status monitoring of substation switch cabinets

Smart city:Smart street lights,security camera cluster control