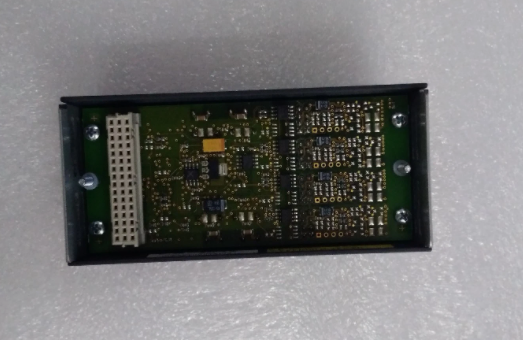

描述

一、核心功能与技术参数

1.基本信息

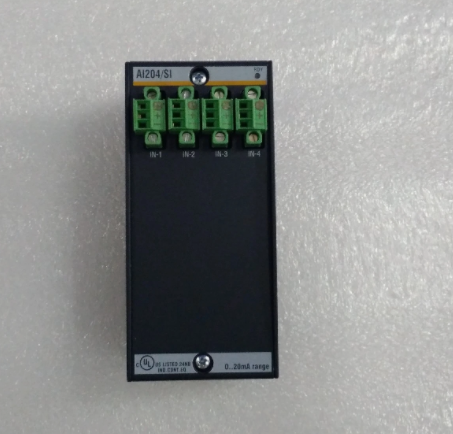

品牌:BACHMANN(德国)

型号:AI204/SI

类型:模拟输入模块

定位:工业自动化系统中的高精度信号采集模块,适用于过程控制、能源管理等领域。

2.功能特性

信号输入:

支持4-20mA或0-20mA电流输入,兼容单端或差分连接方式。

输入阻抗75Ω,采样重复时间250ms/通道。

分辨率与精度:

16位分辨率,LSB(最低有效位)值为305μV,适用于高精度测量场景(如温度、压力监测)。

隔离设计:

通道间隔离(>100dB共模抑制)与系统隔离,有效抑制工业环境中的电磁干扰。

诊断功能:

内部电压监控,支持短路、断线等故障识别。

3.物理与环境参数

通道数量:4个独立隔离的模拟输入通道。

工作电压:支持DC 24V供电,符合工业标准。

环境适应性:

工作温度范围:-20°C至+60°C(需参考具体应用手册)。

二、应用场景

工业过程控制:

用于化工、能源行业的温度、流量、压力等参数的高精度监测与控制。

能源管理:

集成于风电、光伏系统,实现传感器信号的实时采集与分析。

海事工程:

在船舶动力定位系统中,通过CAN总线连接推进器编码器,实时采集转速、扭矩数据,提升控制精度。

机械制造:

监测机械振动、位移等动态参数,优化设备运行效率。

1.Core functions and technical parameters

1.Basic information

Brand:BACHMANN(Germany)

Model:AI204/SI

Type:Analog input module

Positioning:High-precision signal acquisition module in industrial automation systems,suitable for process control,energy management and other fields.

2.Functional characteristics

Signal input:

Supports 4-20mA or 0-20mA current input,compatible with single-ended or differential connection methods.

Input impedance 75Ω,sampling repetition time 250ms/channel.

Resolution and accuracy:

16-bit resolution,LSB(lowest significant bit)value is 305μV,suitable for high-precision measurement scenarios(such as temperature and pressure monitoring).

Isolation design:

Channel isolation(>100dB common mode suppression)isolates from the system to effectively suppress electromagnetic interference in industrial environments.

Diagnostic function:

Internal voltage monitoring,supports short circuit,line breakage and other fault identification.

3.Physical and environmental parameters

Number of channels:4 independently isolated analog input channels.

Working voltage:Supports DC 24V power supply,complies with industrial standards.

Environmental adaptability:

Operating temperature range:-20°C to+60°C(refer to the specific application manual).

2.Application scenarios

Industrial process control:

It is used for high-precision monitoring and control of temperature,flow,pressure and other parameters in the chemical and energy industries.

Energy Management:

Integrated in wind power and photovoltaic systems,real-time acquisition and analysis of sensor signals.

Maritime Engineering:

In the ship’s power positioning system,the thruster encoder is connected to the CAN bus to collect speed and torque data in real time to improve control accuracy.

Machinery manufacturing:

Monitor dynamic parameters such as mechanical vibration and displacement to optimize equipment operation efficiency.