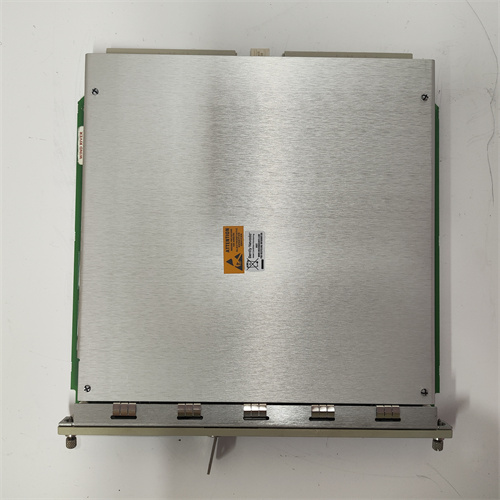

描述

Bentley Nevada 3500-22M 138607-01是一款瞬态数据接口(TDI)模块,主要用于3500监测系统与兼容软件之间的数据交互,以下为该产品的详细介绍:

一、核心功能

数据采集与传输:

稳态与瞬态数据采集:TDI能够连续采集稳态和瞬态的波形数据,这对于分析机械设备的运行状态和诊断潜在问题至关重要。

高速数据传输:通过以太网连接,TDI能够将采集到的数据快速传输到主计算机软件,确保数据的实时性和准确性。

系统集成与兼容性:

兼容3500监测系统:作为3500监测系统的一部分,TDI与系统内的其他模块无缝集成,共同完成机械设备的监测任务。

支持多种软件:TDI与System 1状态监测和诊断软件以及3500系统配置软件兼容,方便用户进行数据分析和系统配置。

功能集成与扩展性:

集成RIM与TDXnet功能:TDI结合了3500/20机架接口模块(RIM)的功能和TDXnet等通信处理器的数据收集功能,提供了更全面的数据采集和处理能力。

支持动态数据采集:使用可选的通道启用磁盘,TDI还能捕获动态和高分辨率瞬态数据,满足用户对高精度数据的需求。

二、技术特性

硬件接口与配置:

I/O模块设计:TDI I/O模块具有2针连接器,用于将信号公共端连接到机架的单点仪表接地端,确保信号传输的稳定性。

按键信号输入:支持四个3500系统按键信号,方便用户进行操作和控制。

系统兼容性与稳定性:

与M系列监视器兼容:TDI可以与M系列监视器(如3500/40M、3500/42M等)连接,为各种旋转设备的监测和诊断提供关键数据。

冗余设计(针对TMR应用):对于三模冗余(TMR)应用,3500系统需要一个TMR版本的TDI,该版本执行“监控通道比较”,确保系统的冗余性和可靠性。

Bentley Nevada 3500-22M 138607-01 is a transient data interface(TDI)module,which is mainly used for data interaction between the 3500 monitoring system and compatible software.The following is a detailed introduction to the product:

I.Core functions

Data acquisition and transmission:

Steady-state and transient data acquisition:TDI can continuously collect steady-state and transient waveform data,which is essential for analyzing the operating status of mechanical equipment and diagnosing potential problems.

High-speed data transmission:Through Ethernet connection,TDI can quickly transmit the collected data to the main computer software to ensure the real-time and accuracy of the data.

System integration and compatibility:

Compatible with 3500 monitoring system:As part of the 3500 monitoring system,TDI seamlessly integrates with other modules in the system to jointly complete the monitoring tasks of mechanical equipment.

Support for multiple software:TDI is compatible with System 1 condition monitoring and diagnostic software and 3500 system configuration software,which is convenient for users to perform data analysis and system configuration.

Functional integration and scalability:

Integrated RIM and TDXnet functions:TDI combines the functions of the 3500/20 rack interface module(RIM)and the data collection functions of communication processors such as TDXnet,providing more comprehensive data collection and processing capabilities.

Support dynamic data acquisition:With the optional channel enable disk,TDI can also capture dynamic and high-resolution transient data to meet users’needs for high-precision data.

2.Technical characteristics

Hardware interface and configuration:

I/O module design:TDI I/O module has a 2-pin connector for connecting the signal common end to the single-point instrument ground of the rack to ensure the stability of signal transmission.

Key signal input:Supports four 3500 system key signals for user operation and control.

System compatibility and stability:

Compatible with M series monitors:TDI can be connected with M series monitors(such as 3500/40M,3500/42M,etc.)to provide key data for monitoring and diagnosis of various rotating equipment.

Redundant design(for TMR applications):For triple modular redundant(TMR)applications,the 3500 system requires a TMR version of TDI,which performs”monitoring channel comparison”to ensure system redundancy and reliability.