描述

一、核心功能与定位

类型:工业级键相输入/输出(I/O)模块,专为机械振动监测和键相信号处理设计,适用于旋转机械设备的实时监测与保护。

核心功能:

键相信号处理:接收来自接近探头或磁性拾波器的输入信号,并将其转换为数字键控相位信号,用于精确测量轴转速、振动振幅及相位。

双通道设计:支持同时处理两个相位信号,提升监测效率。

机械振动监测:检测旋转设备的不平衡、不对中、轴承磨损等机械故障,触发报警或停机保护。

兼容性:与Bently 3500监测系统兼容,支持TMR(三重模块冗余)配置,增强系统可靠性。

二、技术参数

电气特性

工作电压:24V DC(标准配置)。

输入电流:最大10A(部分场景需外部电源支持)。

信号转换:支持接近探头、磁性拾波器等传感器输入,输出数字键控相位信号。

环境适应性

工作温度:

常规模式:0°C至+65°C;

与Keyphasor I/O模块配合时:-30°C至+65°C。

存储温度:-40°C至+85°C。

湿度:95%相对湿度(无冷凝)。

物理特性

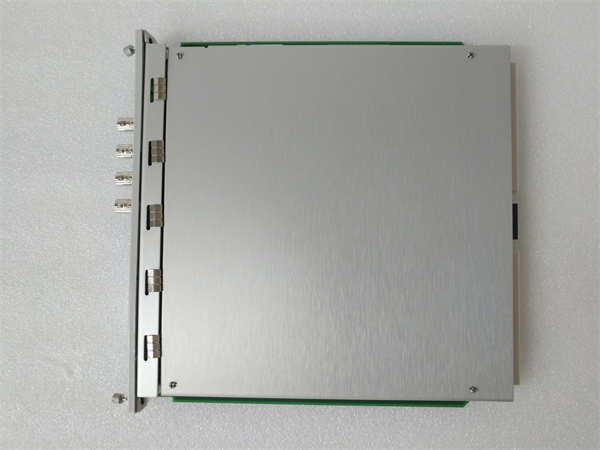

尺寸:24.2cm×11.2cm×2.5cm(半高模块)。

重量:0.38kg。

三、核心应用场景

工业设备监测

电力与能源:监测发电机、汽轮机等旋转设备的振动与转速,保障发电厂稳定运行。

石油与化工:检测压缩机、泵类设备的机械状态,预防突发故障。

制造业:监控机床、生产线中的关键旋转部件,提升生产效率。

故障诊断与保护

实时分析振动数据,识别不平衡、不对中、轴承磨损等问题,触发报警或停机指令。

支持机械完整性评估,确保设备长期可靠运行。

系统集成

作为Bently 3500监测系统的组成部分,与传感器、前置器(如3300 XL系列)协同工作,实现数据采集与传输。

125768-01

125768-01

1.Core functions and positioning

Type:Industrial-grade key phase input/output(I/O)module,designed for mechanical vibration monitoring and key phase signal processing,suitable for real-time monitoring and protection of rotating mechanical equipment.

Core functions:

Key phase signal processing:Receive input signals from proximity probes or magnetic pickups and convert them into digital keyed phase signals for precise measurement of shaft speed,vibration amplitude and phase.

Dual-channel design:supports processing of two phase signals at the same time to improve monitoring efficiency.

Mechanical vibration monitoring:detects mechanical failures such as imbalance,misalignment,bearing wear and other rotating equipment,and triggers alarm or shutdown protection.

Compatibility:Compatible with Bently 3500 monitoring system,supports TMR(triple module redundancy)configuration,and enhances system reliability.

2.Technical parameters

Electrical characteristics

Operating voltage:24V DC(standard configuration).

Input current:maximum 10A(some scenarios require external power supply support).

Signal conversion:supports sensor input such as proximity probes,magnetic pickups,etc.,and outputs digital keyed phase signals.

Environmental adaptability

Operating temperature:

Normal scale:0°C to+65°C;

When compatible with Keyphasor I/O module:-30°C to+65°C.

Storage temperature:-40°C to+85°C.

Humidity:95%relative humidity(no condensation).

Physical characteristics

Size:24.2cm×11.2cm×2.5cm(half-height module).

Weight:0.38kg.

3.Core application scenarios

Industrial equipment monitoring

Electricity and energy:Monitor the vibration and speed of rotating equipment such as generators and steam turbines to ensure the stable operation of the power plant.

Petroleum and Chemical Industry:Detect the mechanical status of compressors and pump equipment to prevent sudden failures.

Manufacturing:Monitor key rotating components in machine tools and production lines to improve production efficiency.

Troubleshooting and protection

Analyze vibration data in real time,identify problems such as imbalance,misalignment,bearing wear,etc.,and trigger alarm or shutdown instructions.

Supports mechanical integrity assessment to ensure long-term and reliable operation of equipment.

System integration

As an integral part of the Bently 3500 monitoring system,it works in conjunction with sensors and presets(such as the 3300 XL series)to realize data acquisition and transmission.