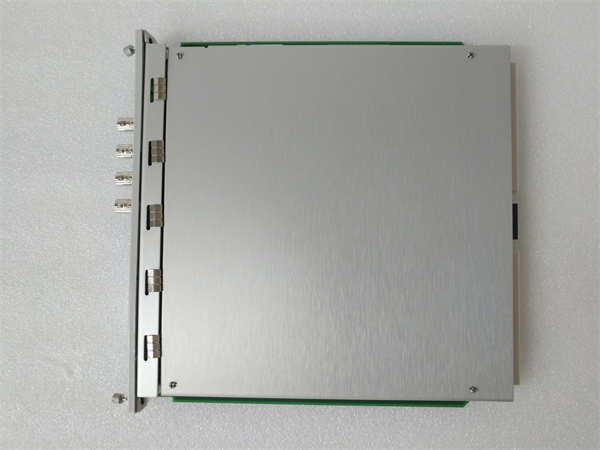

描述

BENTLY 330103-00-04-10-02-00是本特利(Bently Nevada)公司开发的电涡流传感器系统核心组件之一,主要用于工业设备的振动、位移、转速等参数的非接触式监测。以下是其关键特性和应用领域的综合介绍:

一、产品分类与功能

传感器类型

-属于3300 XL系列电涡流传感器系统,采用8mm探头设计,适用于油膜轴承、压缩机、汽轮机等旋转机械的振动和位移测量。

-兼容径向振动、轴向位移、键相位和转速等多场景监测需求。

系统组成

-探头:由耐高温塑料封装的线圈和不锈钢外壳构成,支持标准螺纹(如M10×1)安装。

-延伸电缆:提供标准或铠装版本,用于传输原始信号,支持5/9米或1米系统长度配置。

-前置器:负责信号调理,支持-17.5Vdc至-26Vdc电源输入,线性范围可达2mm,推荐间隙设定值为1.27mm。

二、技术参数

灵敏度:7.87V/mm(200mV/mil),支持用户可编程调整为100mV/mil或200mV/mil。

频率响应:0-10kHz(从探头到监测器的传输距离可达305米)。

温度范围:探头工作温度-52°C至+177°C,延伸电缆可达+260°C,前置器为-52°C至+100°C。

三、应用领域

电力与能源

-汽轮机、发电机的轴振动监测,防止因振动过大引发设备故障。

-火力发电厂的差胀测量,确保转子与定子的热膨胀匹配。

石油化工

-压缩机、离心泵的转速与位移监测,预防密封失效或机械故障。

-高温环境下(如炼油设备)的非接触式位移测量。

冶金与机械制造

-齿轮箱、轧钢机的振动分析,优化设备维护周期。

-风机、空分机的键相位信号采集,确保同步运行。

四、系统优势

高精度与稳定性:符合API 670标准,线性误差±0.33%,温度漂移极低。

互换性:探头、延伸电缆、前置器可完全互换,无需单独校准。

抗干扰能力:前置器满足欧洲电磁兼容标准,适合工业复杂电磁环境。

五、配套监测系统

3500系列监测器:可与3500/40M位移监测器、3500/42振动模块等设备集成,实现数据采集与报警功能。

2300/20双通道监测器:适用于低成本、紧凑型监测场景。

125388-01H

BENTLY 330103-00-04-10-02-00 is one of the core components of the eddy current sensor system developed by Bently Nevada,mainly used for non-contact monitoring of parameters such as vibration,displacement,and speed of industrial equipment.The following is a comprehensive introduction to its key features and application areas:

I.Product classification and function

Sensor type

-Belongs to the 3300 XL series eddy current sensor system,adopts 8mm probe design,suitable for vibration and displacement measurement of rotating machinery such as oil film bearings,compressors,and steam turbines.

-Compatible with multi-scenario monitoring requirements such as radial vibration,axial displacement,key phase and speed.

System composition

-Probe:It is composed of a coil encapsulated in high-temperature resistant plastic and a stainless steel shell,and supports standard thread(such as M10×1)installation.

-Extension cable:Standard or armored version is available for transmitting original signals,supporting 5/9 meters or 1 meter system length configuration.

-Preamplifier:responsible for signal conditioning,supports-17.5Vdc to-26Vdc power input,linear range up to 2mm,recommended gap setting value is 1.27mm.

2.Technical parameters

Sensitivity:7.87V/mm(200mV/mil),supports user programmable adjustment to 100mV/mil or 200mV/mil.

Frequency response:0-10kHz(transmission distance from probe to monitor up to 305 meters).

Temperature range:probe operating temperature-52°C to+177°C,extension cable up to+260°C,preamplifier-52°C to+100°C.

3.Application areas

Power and energy

-Shaft vibration monitoring of steam turbines and generators to prevent equipment failures caused by excessive vibration.

-Differential expansion measurement in thermal power plants to ensure thermal expansion matching between rotors and stators.

Petrochemicals

-Speedand displacement monitoring of compressors and centrifugal pumps to prevent seal failure or mechanical failure.

-Non-contact displacement measurement in high temperature environments(such as refining equipment).

Metallurgy and machinery manufacturing

-Vibration analysis of gearboxes and rolling mills to optimize equipment maintenance cycles.

-Key phase signal acquisition of fans and air separators to ensure synchronous operation.

IV.System advantages

High precision and stability:Meets API 670 standard,linear error±0.33%,and extremely low temperature drift.

Interchangeability:Probes,extension cables,and preamplifiers are fully interchangeable without separate calibration.

Anti-interference ability:The preamplifier meets European electromagnetic compatibility standards and is suitable for complex industrial electromagnetic environments.

V.Supporting monitoring system

3500 series monitors:can be integrated with 3500/40M displacement monitors,3500/42 vibration modules and other equipment to achieve data acquisition and alarm functions.

2300/20 dual-channel monitor:suitable for low-cost,compact monitoring scenarios.