描述

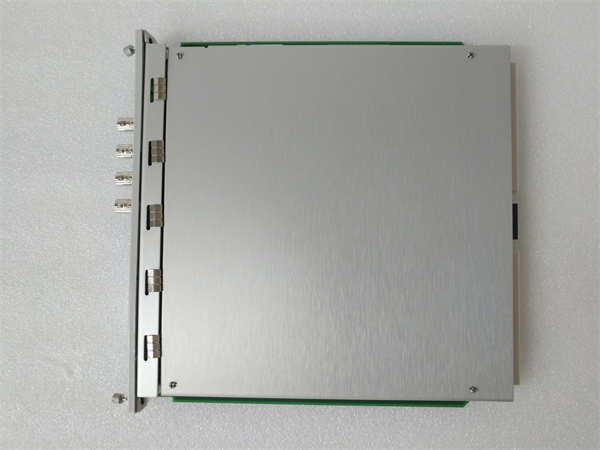

BENTLY 3500/22M 138607-01瞬态数据接口模块技术说明

核心功能

高性能数据采集

支持22个通道稳态与瞬态动态(波形)数据采集,采样率高达102.4 kHz,满足高精度振动、位移、速度等参数监测需求。

通过可选的动态通道启用磁盘,可捕获高分辨率瞬态数据,如设备启停、故障前后的波形变化。

实时数据传输

通过以太网链路实时传输数据至主机软件(如System 1状态监控与诊断软件),支持RS232、RS485、100Base-FX光纤等多种通信协议,确保工业环境下的稳定传输。

系统兼容性与集成

作为3500监测系统与兼容软件(如System 1、3500系统组态软件)的核心接口,整合RIM(机架接口模块)与TDXnet通信处理器功能,简化系统架构。

与M系列监测器(如3500/40M、3500/42M)无缝对接,支持多传感器扩展。

技术参数

通道配置:22通道瞬态数据采集,支持动态与静态数据混合捕获。

采样率:最高102.4 kHz(瞬态模式),满足高频信号捕捉需求。

通信接口:

以太网(10/100Base-T、100Base-FX光纤)

RS232/RS485串口(可选)。

物理规格:

尺寸:229mm×140mm×48mm

重量:1.0 kg

功耗:10.5 W(典型值)。

安全与可靠性

冗余设计:支持TMR(三重模块冗余)配置,通过连续通道比较功能检测输出一致性,确保关键监控路径的可靠性。

环境适应性:适用于工业恶劣环境(-40°C至85°C),抗振动、抗干扰,支持带电插拔维护。

报警数据捕捉:

静态值:事件前10分钟至事件后1分钟(1秒间隔),事件前20秒至事件后10秒(100毫秒间隔)。

波形数据:事件前2.5分钟至事件后1分钟(10秒间隔),支持动态故障分析。

应用场景

工业监测:汽轮机、压缩机、泵、齿轮箱等旋转机械的振动、位移、速度实时监测。

故障诊断:通过瞬态波形分析设备启停、异常工况下的机械状态,预防突发故障。

过程控制:电力、石油化工、冶金、航空航天等领域中的精密设备保护与性能优化。

BENTLY 3500/22M 138607-01 Technical description of transient data interface module

Core functions

High-performance data acquisition

Supports 22 channels of steady-state and transient dynamic(waveform)data acquisition,with a sampling rate of up to 102.4 kHz,meeting the monitoring needs of high-precision vibration,displacement,speed and other parameters.

Enable disks with optional dynamic channels can capture high-resolution transient data such as device start-stop,waveform changes before and after failure.

Real-time data transmission

Transfer data in real time to host software(such as System 1 status monitoring and diagnostic software)through Ethernet links,and supports a variety of communication protocols such as RS232,RS485,100Base-FX fiber,etc.,ensuring stable transmission in an industrial environment.

System compatibility and integration

As the core interface between the 3500 monitoring system and compatible software(such as System 1 and 3500 system configuration software),it integrates the functions of RIM(rack interface module)and TDXnet communication processor to simplify the system architecture.

Seamlessly docked with M series monitors(such as 3500/40M,3500/42M),supporting multi-sensor expansion.

Technical parameters

Channel configuration:22 channels of transient data acquisition,supporting mixed capture of dynamic and static data.

Sampling rate:up to 102.4 kHz(transient mode),meeting the needs of high-frequency signal capture.

Communication interface:

Ethernet(10/100Base-T,100Base-FX fiber)

RS232/RS485 serial port(optional).

Physical specifications:

Size:229mm×140mm×48mm

Weight:1.0 kg

Power consumption:10.5 W(typ.).

Safety and reliability

Redundant design:supports TMR(triple module redundancy)configuration,detects output consistency through continuous channel comparison function to ensure the reliability of critical monitoring paths.

Environmental adaptability:Suitable for industrial harsh environments(-40°C to 85°C),anti-vibration and anti-interference,and supports live plug-and-unplug-and-unplug-and-unplug-and-repair.

Alarm data capture:

Static value:10 minutes before the event to 1 minute after the event(1 second interval),20 seconds before the event to 10 seconds after the event(100 millisecond interval).

Waveform data:2.5 minutes before the event to 1 minute after the event(10 second interval),supports dynamic fault analysis.

Application scenarios

Industrial monitoring:Real-time monitoring of vibration,displacement and speed of rotating machinery such as steam turbines,compressors,pumps,gear boxes.

Fault diagnosis:Prevent sudden failures by analyzing the mechanical state of the equipment when it starts and stops and abnormal working conditions.

Process control:Precision equipment protection and performance optimization in the fields of electricity,petrochemicals,metallurgy,aerospace,etc.