描述

一、产品概述

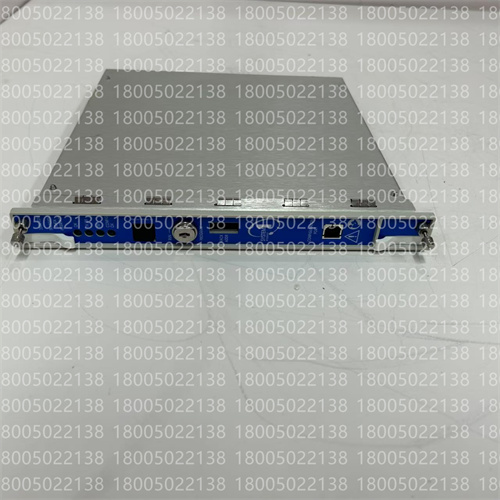

类型:瞬态数据接口模块(TDI)

系列:Bently 3500监测系统核心组件

定位:

-实现工业设备(如汽轮机、压缩机、发电机)的振动、位移等动态参数的高速采集与传输;

-作为3500机架与上层分析软件(如System 1)之间的数据桥梁。

二、核心功能与特性

数据采集与传输

-瞬态数据捕获:支持高分辨率波形数据采集(需配合通道启用磁盘);

-通信能力:通过以太网传输数据,兼容TCP/IP、TDXnet等协议;

-冗余设计:支持双通道通信,提升系统可靠性。

信号处理与兼容性

-传感器接口:兼容M系列监测器(如3500/40M、3500/42M);

-信号处理:内置高速ADC与数字滤波,支持频谱分析、趋势监测。

系统集成

-机架配置:固定安装于3500机架插槽1(靠近电源),替代传统RIM模块;

-非关键路径:不影响设备保护系统的主监控流程。

三、技术参数

|项目|参数|

|功耗|10.5W|

|通信接口|以太网(10/100Base-TX)、USB-B|

|数据采集速率|高达500kHz(动态模式)|

|存储容量|内置非易失性存储(可扩展)|

|环境适应性|工业级设计,支持宽温运行(-20°C~60°C)|

四、典型应用场景

旋转机械监测:汽轮机、压缩机、风力发电机等设备的振动与位移实时监控;

预测性维护:通过瞬态数据分析轴承磨损、不平衡等早期故障;

工业物联网(IIoT):数据远程上传至云端平台,支持边缘计算与AI诊断。

1.Product Overview

Type:Transient Data Interface Module(TDI)

Series:Core components of Bently 3500 monitoring system

position:

-Realize high-speed acquisition and transmission of dynamic parameters such as vibration and displacement of industrial equipment(such as steam turbines,compressors,generators);

-As a data bridge between 3500 racks and upper-layer analysis software(such as System 1).

2.Core functions and characteristics

Data acquisition and transmission

-Transient data capture:supports high-resolution waveform data acquisition(disk required to be enabled with channel);

-Communication capability:transmit data through Ethernet,compatible with TCP/IP,TDXnet and other protocols;

-Redundant design:supports dual-channel communication to improve system reliability.

Signal processing and compatibility

-Sensor interface:compatible with M series monitors(such as 3500/40M,3500/42M);

-Signal processing:Built-in high-speed ADC and digital filtering,supporting spectrum analysis and trend monitoring.

System integration

-Rack configuration:fixedly installed in 3500 rack slot 1(near the power supply),replacing the traditional RIM module;

-Non-critical path:does not affect the main monitoring process of the equipment protection system.

3.Technical parameters

|Project|Parameters|

|Power consumption|10.5W|

|Communication interface|Ethernet(10/100Base-TX),USB-B|

|Data acquisition rate|Up to 500kHz(dynamic mode)|

|Storage capacity|Built-in nonvolatile storage(scalable)|

|Environmental adaptability|Industrial-grade design,supports wide temperature operation(-20°C~60°C)|

4.Typical application scenarios

Rotary machinery monitoring:real-time monitoring of vibration and displacement of equipment such as steam turbines,compressors,wind turbines and other equipment;

Predictive maintenance:analyze early failures such as bearing wear,imbalance,etc.through transient data;

Industrial Internet of Things(IIoT):Data is remotely uploaded to the cloud platform,supporting edge computing and AI diagnosis.