描述

主要特性和功能

60M100是一款功能强大、用途广泛的系统,其紧凑坚固的装置兼具基本监控和高级信号处理功能。其主要目的是通过提前数月检测缺陷和潜在故障来促进基于状态的维护(CBM),从而有助于避免停机并降低维护成本。

以下是其主要特性的细分:

持续监控:实时、持续地监控风力涡轮机内的关键旋转和静止部件。

先进的信号处理:利用先进的算法分析动态信号(例如来自加速度计的信号),并提取数十种测量值和健康指标。这些通常可以根据特定的轴承和齿轮箱特性进行定制调整。

机器运行状态感知:将机器运行状态集成到其分析中,从而根据涡轮机的当前运行模式(例如发电、怠速、制动)实现更智能的报警和诊断。

早期故障检测:旨在识别以下部件中正在发生的问题:

塔架摇摆

主轴承

主旋翼

齿轮箱(所有内部轴承、齿轮啮合、碎片监测)

发电机轴承

发电机接地

输入功能:

支持最多12个动态通道输入(例如,来自两线ICP型加速度计)。

包含两个Keyphasor®信号,用于速度和相位参考。

能够接收来自各种传感器类型的输入。

数据采集和处理:

高动态范围(例如,110 dB)。

高分辨率A/D转换(例如,标称24位)。

宽带宽(例如,0至40 kHz)。

报警和诊断:

将调节后的信号与用户可编程的报警(警告和报警级别)进行比较。

提供高分辨率波形数据和趋势线,方便进行详细分析。

所有报警状态通常都锁定。

通信:

包含两个独立的以太网端口(10/100 BaseT)用于数字通信,可连接到ADAPT软件并通过以太网TCP/IP与过程控制系统集成。

一个端口通常用作网络DHCP端口(Net A),另一个端口用作本地静态IP端口(Net B)。

还可以包含缓冲信号输出(例如,通过15针D-SUB连接器)。

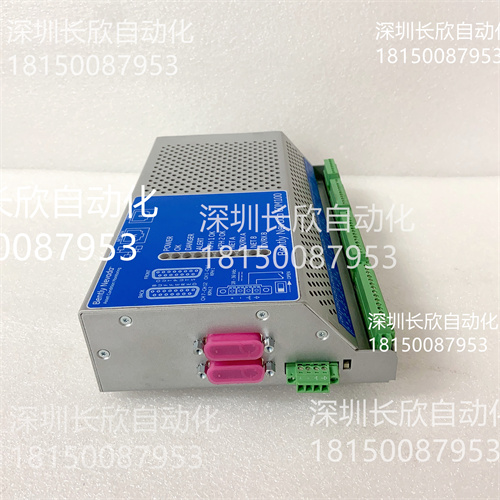

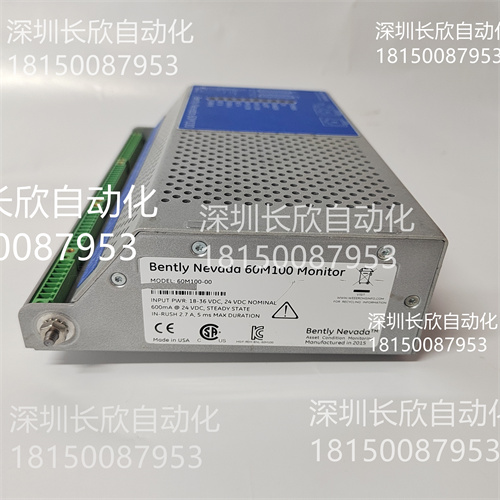

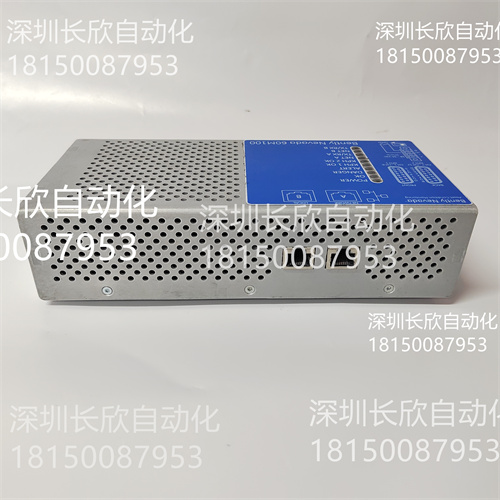

坚固紧凑的设计:

可承受恶劣的工业环境,包括宽温度范围(通常为-40°C至+70°C)。

可采用多种安装配置:面板安装、机架安装或隔板安装。

输入电源:通常为18-36 VDC(标称24 VDC)。

软件集成:与Bently Nevada的ADAPT软件协同工作,实现全面的数据可视化、分析和报告。

应用

Bently Nevada 60M100-00专为以下应用而设计:

风力涡轮机状态监测:其主要应用是对风力涡轮机传动系统和结构进行持续在线监测,这些设备是复杂且关键的资产。

资产绩效管理:通过提供潜在问题的早期预警,它支持预测性维护策略,减少计划外停机时间并优化风电场的运营效率。

Key Features and Functions

The 60M100 is a powerful and versatile system that provides both basic monitoring and advanced signal processing capabilities in a compact,rugged unit.Its main purpose is to facilitate condition-based maintenance(CBM)by detecting defects and potential failures months in advance,helping to prevent downtime and reduce maintenance costs.

Here’s a breakdown of its key features:

Continuous Monitoring:Provides real-time,ongoing monitoring of critical rotating and stationary components within a wind turbine.

Sophisticated Signal Processing:Utilizes advanced algorithms to analyze dynamic signals(e.g.,from accelerometers)and extract dozens of measurements and health indices.These can often be custom-tuned to specific bearing and gearbox characteristics.

Machine Operating State Awareness:Integrates machine operating states into its analysis,allowing for more intelligent alarming and diagnostics based on the turbine’s current operational mode(e.g.,generating power,idling,braking).

Early Fault Detection:Designed to identify developing issues in components like:

Tower sway

Main bearing

Main rotor

Gearboxes(all internal bearings,gear meshes,debris monitoring)

Generator bearings

Generator grounding

Input Capabilities:

Supports up to 12 dynamic channel inputs(e.g.,from 2-wire ICP type accelerometers).

Includes two Keyphasor®signals for speed and phase reference.

Capable of taking input from various sensor types.

Data Acquisition and Processing:

High dynamic range(e.g.,110 dB).

High-resolution A/D conversion(e.g.,24 bits nominal).

Wide bandwidth(e.g.,0 to 40 kHz).

Alarming and Diagnostics:

Compares conditioned signals with user-programmable alarms(warning and alarm levels).

Provides high-resolution waveform data and trendlines for detailed analysis.

All alarm statuses are typically latching.

Communication:

Includes two independent Ethernet ports(10/100 BaseT)for digital communication,allowing connection to ADAPT software and integration with process control systems via Ethernet TCP/IP.

One port often acts as a Network DHCP Port(Net A)and the other as a Local Static IP Port(Net B).

May also include buffered signal outputs(e.g.,via 15-pin D-SUB connectors).

Robust and Compact Design:

Built to withstand harsh industrial environments,including wide temperature ranges(typically-40°C to+70°C).

Can be mounted in various configurations:panel mount,rackmount,or bulkhead.

Input Power:Typically 18-36 VDC(24 VDC nominal).

Integration with Software:Works in conjunction with Bently Nevada’s ADAPT software for comprehensive data visualization,analysis,and reporting.

Applications

The Bently Nevada 60M100-00 is specifically engineered for:

Wind Turbine Condition Monitoring:Its primary application is to provide continuous,online monitoring of wind turbine drivetrains and structures,which are complex and critical assets.

Asset Performance Management:By providing early warnings of potential issues,it supports predictive maintenance strategies,reducing unplanned downtime and optimizing the operational efficiency of wind farms.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101