描述

一、产品定位与核心优势

1.品牌与产品线归属

BERGER LAHR(现为WITTENSTEIN Motion Control旗下品牌):

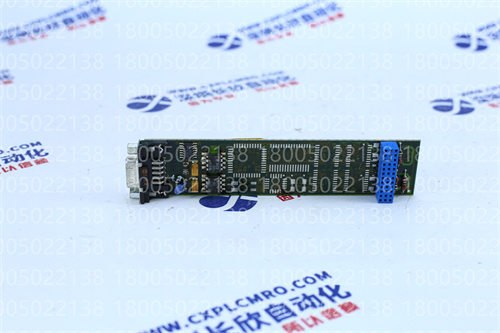

RS232-A01是BERGER LAHR驱动器/控制器的标准串行通信模块,主要用于步进电机或伺服驱动器与上位机(如PLC、PC、HMI)之间的RS-232通信。

核心优势:

兼容性强:支持标准RS-232协议,可与多数工业设备无缝对接。

稳定可靠:采用光电隔离设计,有效抑制工业现场电磁干扰(EMI)。

灵活配置:支持自定义波特率、数据位、停止位,适应不同设备通信需求。

低成本解决方案:相比以太网或现场总线模块,RS-232接口成本更低,适合预算有限的项目。

2.典型应用场景

步进电机控制:

通过RS-232发送脉冲/方向信号或位置指令,控制BERGER LAHR步进驱动器(如DRS系列)实现精准定位。

伺服系统调试:

连接伺服驱动器(如BERGER LAHR SDS系列),通过串口命令调整PID参数、速度环增益等。

数据采集与监控:

读取驱动器状态(如电流、温度、报警信息)并上传至SCADA系统或HMI界面。

设备联调:

在多轴运动控制场景中,通过RS-232菊花链连接实现主从式通信,简化布线。

二、技术参数详解

1.通信接口参数

参数类别规格详情

接口类型RS-232(D-sub 9针母头)

通信协议标准ASCII命令集(兼容BERGER LAHR驱动器指令集)

波特率1200~115200 bps(可配置)

数据位7/8位(默认8位)

停止位1/2位(默认1位)

校验位无/奇/偶校验(默认无校验)

流控无硬件流控(RTS/CTS可选)

最大通信距离15 m(标准RS-232,无中继)

2.电气参数

参数类别规格详情

供电方式由驱动器内部供电(无需外部电源)

工作电压5 V DC(典型值,依驱动器型号)

功耗≤0.5 W(静态)

隔离电压1500 V DC(光电隔离,输入/输出端隔离)

ESD保护IEC 61000-4-2:±8 kV接触放电

±15 kV空气放电

1.Product positioning and core advantages

1.Brand and product line ownership

BERGER LAHR(now a brand of WITTENSTEIN Motion Control):

RS232-A01 is a standard serial communication module for BERGER LAHR drivers/controllers,mainly used for RS-232 communication between stepper motors or servo drivers and host computers(such as PLC,PC,HMI).

Core advantages:

Strong compatibility:supports standard RS-232 protocol and can be seamlessly connected with most industrial equipment.

Stable and reliable:adopts optoelectronic isolation design to effectively suppress electromagnetic interference(EMI)in industrial sites.

Flexible configuration:supports custom baud rate,data bit,stop bit,and adapts to the communication needs of different devices.

Low-cost solution:Compared with Ethernet or fieldbus modules,RS-232 interface has lower cost and is suitable for projects with limited budgets.

2.Typical application scenarios

Stepper motor control:

Send pulse/direction signals or position commands via RS-232 to control BERGER LAHR stepper drivers(such as DRS series)to achieve precise positioning.

Servo system debugging:

Connect servo drivers(such as BERGER LAHR SDS series)and adjust PID parameters,speed loop gain,etc.through serial port commands.

Data acquisition and monitoring:

Read driver status(such as current,temperature,alarm information)and upload to SCADA system or HMI interface.

Equipment joint debugging:

In multi-axis motion control scenarios,master-slave communication is achieved through RS-232 daisy chain connection to simplify wiring.

2.Technical parameter details

1.Communication interface parameters

Parameter category Specification details

Interface type RS-232(D-sub 9-pin female)

Communication protocol Standard ASCII command set(compatible with BERGER LAHR drive instruction set)

Baud rate 1200~115200 bps(configurable)

Data bits 7/8 bits(default 8 bits)

Stop bits 1/2 bits(default 1 bit)

Parity bit None/odd/even parity(default no parity)

Flow control No hardware flow control(RTS/CTS optional)

Maximum communication distance 15 m(standard RS-232,no relay)

2.Electrical parameters

Parameter category Specification details

Power supply method Powered by the drive internally(no external power supply required)

Working voltage 5 V DC(typical value,depending on the drive model)

Power consumption≤0.5 W(static)

Isolation voltage 1500 V DC(photoelectric isolation,input/output isolation)

ESD protection IEC 61000-4-2:±8 kV contact discharge

±15 kV air discharge

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101