描述

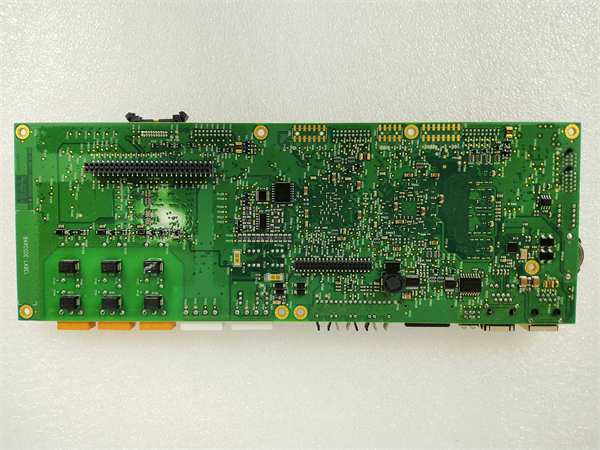

Brooks Automation 001-4130-03是一款专为半导体制造领域设计的高精度对准控制器,兼具运动控制与自动化管理功能。以下是其核心特性和应用场景的综合概述:

一、核心功能与技术参数

高精度定位

-支持纳米级定位精度(部分场景可达±5μm),适用于晶圆对准、光刻、蚀刻等工艺,确保电路图案精确转移与材料去除均匀性。

-集成线性编码器、激光干涉仪等传感器,实时反馈位置信息并优化控制策略。

动态响应与多轴联动

-响应时间小于1秒,支持多轴同步控制(如晶圆台的平移、旋转与倾斜),满足复杂运动路径规划需求。

-兼容步进电机与伺服电机,适配不同负载与速度要求。

通信与集成能力

-支持RS-232/485、Modbus TCP/IP、Profinet等工业协议,可无缝对接PLC、DCS系统及上位机软件。

-提供图形化用户界面,支持手持教学吊坠(Teach Pendant)编程,简化操作流程。

可靠性与环境适应性

-采用冗余电源与通信链路设计,单点故障下仍保持系统可用性。

-防护等级IP65,适应洁净室的静电防护与微粒污染控制要求。

二、典型应用场景

半导体制造工艺

-光刻:对准晶圆与掩模,确保曝光图案精度。

-蚀刻:控制晶圆对准掩模,实现选择性材料去除。

-计量:与测量工具对齐,进行晶圆缺陷检测。

扩展应用领域

-生命科学:药物制造中的自动化监测与质量控制。

-工业自动化:材料处理系统中的实时监控与设备联动。

三、技术优势

高级算法优化:内置算法可减少对准偏差,提升工艺一致性。

故障诊断与维护:自诊断功能实时监控系统健康状态,提供故障代码与维修建议。

模块化扩展:支持与其他Brooks Automation设备协同工作,构建完整自动化生产线。

1MRK002133-ABr02

1MRK002133-ABr02

Brooks Automation 001-4130-03 is a high-precision alignment controller designed for semiconductor manufacturing,combining motion control and automation management functions.The following is a comprehensive overview of its core features and application scenarios:

I.Core functions and technical parameters

High-precision positioning

-Supports nanometer-level positioning accuracy(up to±5μm in some scenarios),suitable for wafer alignment,lithography,etching and other processes,ensuring accurate transfer of circuit patterns and uniformity of material removal.

-Integrates sensors such as linear encoders and laser interferometers to provide real-time feedback of position information and optimize control strategies.

Dynamic response and multi-axis linkage

-The response time is less than 1 second,supporting multi-axis synchronous control(such as translation,rotation and tilt of the wafer stage)to meet the needs of complex motion path planning.

-Compatible with stepper motors and servo motors,adapting to different load and speed requirements.

Communication and integration capabilities

-Supports industrial protocols such as RS-232/485,Modbus TCP/IP,Profinet,etc.,and can seamlessly connect to PLC,DCS systems and host computer software.

-Provides a graphical user interface,supports handheld teaching pendant programming,and simplifies the operation process.

Reliability and environmental adaptability

-Redundant power supply and communication link design are adopted to maintain system availability under single point failure.

-Protection level IP65,adapt to the electrostatic protection and particle contamination control requirements of clean rooms.

2.Typical application scenarios

Semiconductor manufacturing process

-Lithography:Align wafers and masks to ensure exposure pattern accuracy.

-Etching:Control wafer alignment mask to achieve selective material removal.

-Metrology:Align with measurement tools to detect wafer defects.

Extended application areas

-Life sciences:Automated monitoring and quality control in drug manufacturing.

-Industrial automation:Real-time monitoring and equipment linkage in material handling systems.

3.Technical advantages

Advanced algorithm optimization:Built-in algorithms can reduce alignment deviations and improve process consistency.

Fault diagnosis and maintenance:The self-diagnosis function monitors the health status of the system in real time,and provides fault codes and repair suggestions.

Modular expansion:Supports collaboration with other Brooks Automation equipment to build a complete automated production line.