描述

一、产品概述

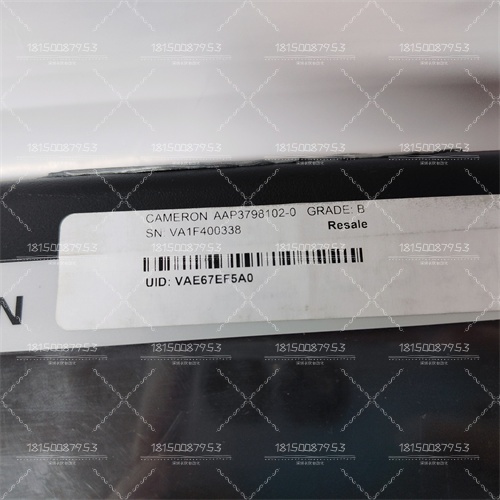

CAMERON AAP3798102-00130是Cameron(现属Schlumberger旗下OneSubsea品牌)生产的一款井口控制面板(Wellhead Control Panel,WHCP)的关键组件,具体可能为液压控制模块、压力传感器、电磁阀或接口模块(需根据实际应用场景确认)。该产品广泛应用于油气田开采中的井口安全控制系统,用于监测和控制井口阀门(如防喷器、节流阀)的液压或电信号,确保钻井、生产过程中的安全操作。

二、技术规格与功能

1.核心功能

液压/电信号控制:

若为电磁阀或控制模块:通过液压或电信号驱动井口阀门(如BOP防喷器)的开启/关闭。

若为传感器:实时监测井口压力、温度或液压系统状态,并将数据传输至中央控制系统。

安全冗余设计:

支持双通道冗余控制,确保单一故障不影响系统安全性。

符合API 16C、API 16D等行业标准,具备紧急关断(ESD)功能。

环境适应性:

适用于海上平台、陆地油田等恶劣环境,具备防爆、防腐、耐高温/低温特性。

2.关键参数(示例,需根据具体型号确认)

参数规格

工作电压24 V DC(电磁阀/传感器)或110/220 V AC(控制模块)

液压范围0~5000 psi(若为液压控制组件)

信号输出4-20 mA(传感器)、开关量(电磁阀)或CAN/Modbus(控制模块)

防护等级IP66/IP68(防尘防水)

防爆认证ATEX Zone 1/2、IECEx、NEPSI(适用于爆炸性气体环境)

工作温度-40℃~+85℃(极端环境型号)

接口类型NPT 1/2″、3/4″(液压接口)或M12/M23(电气接口)

三、典型应用场景

钻井平台井口控制:

集成于BOP(防喷器)控制系统中,在井涌、井喷等紧急情况下快速关闭井口。

生产井口安全监测:

监测井口压力、温度,防止超压或泄漏事故。

水下井口控制:

用于深海油气开发,通过ROV(遥控潜水器)操作或自主控制阀门。

测试与验证:

在工厂测试或现场调试阶段,验证井口设备的响应时间与可靠性。

1.Product Overview

CAMERON AAP3798102-00130 is a key component of a wellhead control panel(WHCP)produced by Cameron(now a OneSubsea brand under Schlumberger).It may be a hydraulic control module,pressure sensor,solenoid valve or interface module(need to be confirmed according to the actual application scenario).This product is widely used in wellhead safety control systems in oil and gas field exploitation.It is used to monitor and control the hydraulic or electrical signals of wellhead valves(such as blowout preventers and throttle valves)to ensure safe operation during drilling and production.

2.Technical specifications and functions

1.Core functions

Hydraulic/electrical signal control:

If it is a solenoid valve or control module:drive the opening/closing of the wellhead valve(such as BOP blowout preventer)through hydraulic or electrical signals.

If it is a sensor:monitor the wellhead pressure,temperature or hydraulic system status in real time,and transmit the data to the central control system.

Safety redundancy design:

Supports dual-channel redundant control to ensure that a single failure does not affect the safety of the system.

It complies with industry standards such as API 16C and API 16D,and has an emergency shutdown(ESD)function.

Environmental adaptability:

Suitable for harsh environments such as offshore platforms and onshore oil fields,with explosion-proof,corrosion-resistant,and high/low temperature resistant properties.

2.Key parameters(example,to be confirmed according to the specific model)

Parameter Specification

Operating voltage 24 V DC(solenoid valve/sensor)or 110/220 V AC(control module)

Hydraulic range 0~5000 psi(if it is a hydraulic control component)

Signal output 4-20 mA(sensor),switch(solenoid valve)or CAN/Modbus(control module)

Protection level IP66/IP68(dust and water proof)

Explosion-proof certification ATEX Zone 1/2,IECEx,NEPSI(suitable for explosive gas environment)

Operating temperature-40℃~+85℃(extreme environment model)

Interface type NPT 1/2″,3/4″(hydraulic interface)or M12/M23(electrical interface)

III.Typical application scenarios

Drilling platform wellhead control:

Integrated in the BOP(blowout preventer)control system to quickly close the wellhead in emergency situations such as well kick and blowout.

Production wellhead safety monitoring:

Monitor wellhead pressure and temperature to prevent overpressure or leakage accidents.

Underwater wellhead control:

Used in deep-sea oil and gas development,valves are operated or autonomously controlled by ROV(remotely operated vehicle).

Testing and verification:

Verify the response time and reliability of wellhead equipment during factory testing or on-site commissioning.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101