描述

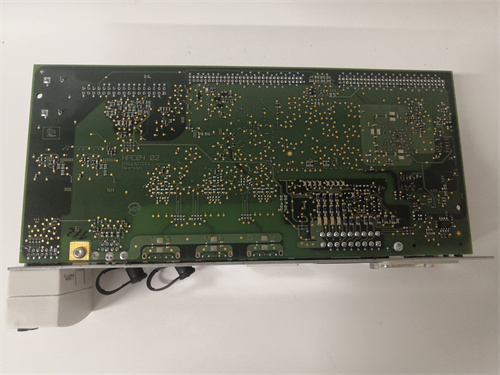

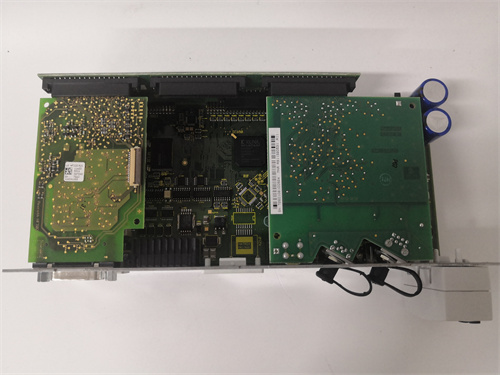

Cisco CSACS-1121-K9是思科(Cisco)公司推出的一款工业控制领域的模块化可编程逻辑控制器(PLC),专为复杂工业环境设计,具备高可靠性、灵活性及扩展性。以下是其核心功能与技术特点的综合解析:

一、产品定位与结构

产品类型:模块化PLC系统

核心架构:由CPU模块、I/O模块、电源模块及底板/机架构成,支持按需组合配置,适用于不同规模的工业控制场景。

二、核心功能与技术优势

高可靠性

-采用现代大规模集成电路技术及抗干扰设计,平均无故障时间可达数十万小时,远超传统继电控制系统。

-内置硬件自检功能,可实时监测系统状态并发出警报,结合外围设备故障诊断程序,实现全系统防护。

数据处理能力

-支持完善的数据运算功能,适用于数字控制领域(如位置控制、温度调节等)。

-集成通信协议,可与上位机、传感器及执行器无缝对接,构建智能化控制系统。

模块化扩展性

-支持I/O模块灵活增减,适配不同工业设备需求(如电机控制、阀门调节等)。

-兼容多种功能单元(如通信模块、伺服控制器),扩展至CNC、温度控制等复杂应用。

环境适应性

-工作温度范围广(具体参数需结合实际型号),防护等级满足工业现场要求,抗电磁干扰能力突出。

三、适用场景

工业自动化:生产线控制、机器人协作、数控机床等。

能源与电力:变频器控制、电机保护、电网监控等。

交通与物流:仓储分拣系统、港口设备自动化等。

过程控制:化工、水处理等行业的压力、温度闭环调节。

四、品牌与认证

制造商背景:思科作为全球领先的网络解决方案供应商,其工业控制产品融合了网络通信技术优势,确保系统集成与数据传输的高效性。

认证标准:符合国际工业设备安全规范,如UL、EN等认证,保障产品合规性。

Cisco CSACS-1121-K9 is a modular programmable logic controller(PLC)in the field of industrial control launched by Cisco.It is designed for complex industrial environments and has high reliability,flexibility and scalability.The following is a comprehensive analysis of its core functions and technical features:

1.Product positioning and structure

Product type:Modular PLC system

Core architecture:It consists of CPU module,I/O module,power module and baseboard/rack,supports on-demand combination configuration,and is suitable for industrial control scenarios of different scales.

2.Core functions and technical advantages

High reliability

-Using modern large-scale integrated circuit technology and anti-interference design,the average failure-free time can reach hundreds of thousands of hours,far exceeding traditional relay control systems.

-Built-in hardware self-check function,which can monitor the system status in real time and issue alarms,combined with peripheral equipment fault diagnosis procedures to achieve full system protection.

Data processing capabilities

-Supports complete data calculation functions,suitable for digital control fields(such as position control,temperature control,etc.).

-Integrated communication protocol,can be seamlessly connected with the host computer,sensors and actuators to build an intelligent control system.

Modular scalability

-Supports flexible addition and reduction of I/O modules to adapt to different industrial equipment requirements(such as motor control,valve adjustment,etc.).

-Compatible with multiple functional units(such as communication modules,servo controllers),and expanded to complex applications such as CNC and temperature control.

Environmental adaptability

-Wide operating temperature range(specific parameters need to be combined with the actual model),protection level meets industrial site requirements,and has outstanding anti-electromagnetic interference ability.

III.Applicable scenarios

Industrial automation:production line control,robot collaboration,CNC machine tools,etc.

Energy and power:inverter control,motor protection,power grid monitoring,etc.

Transportation and logistics:warehousing and sorting systems,port equipment automation,etc.

Process control:closed-loop pressure and temperature regulation in industries such as chemical and water treatment.

IV.Brand and certification

Manufacturer background:Cisco,as a world-leading network solution provider,integrates the advantages of network communication technology in its industrial control products to ensure the efficiency of system integration and data transmission.

Certification standards:Comply with international industrial equipment safety specifications,such as UL,EN and other certifications to ensure product compliance.