描述

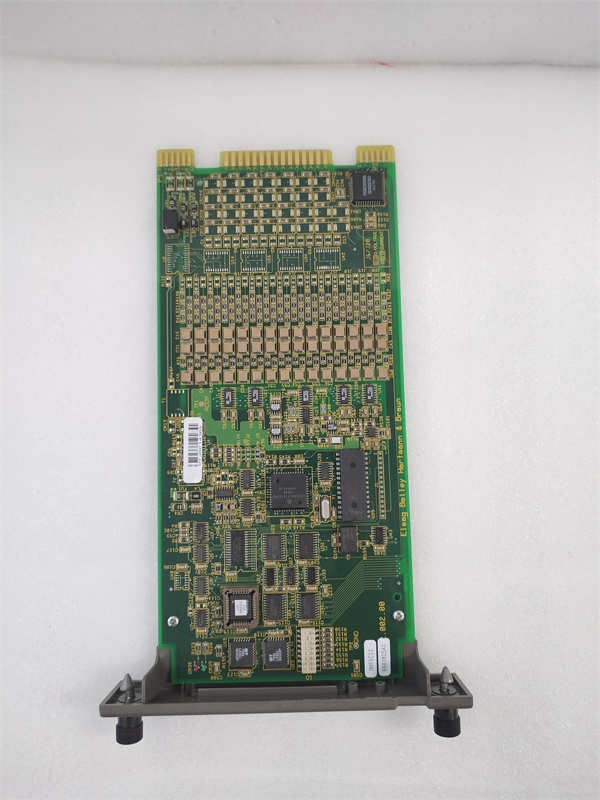

产品概述

MCP-1004是Compressor Controls Corporation(CCC)开发的工业控制器模块,专为压缩机系统控制设计,支持实时监控、多参数调节及通信集成。该模块适用于石油、化工、制冷、气体处理等工业领域,提供高可靠性和环境适应性。

技术参数与功能特点

核心功能

实时监控:

显示发动机转速(单位:rpm)、转速参考、执行器输出百分比、辅助输入电压、远程输入毫安值等实时参数。

支持手持设备查看动态数据,便于调试与校准。

多模式控制:

可配置燃油限制器、扭矩限制器、怠速下降等控制逻辑,适应不同工况需求。

输入/输出接口

模拟输入:支持辅助输入电压(如传感器信号)和远程速度设置输入(毫安信号)。

数字输入/输出:包括运行/停止开关状态监测(离散输入)及执行器控制输出。

执行器反馈:提供电流和位置反馈(电压读数),确保控制精度。

通信与可编程性

协议支持:兼容Modbus等工业通信协议,可集成至SCADA、PLC或HMI系统。

配置灵活性:通过编程菜单调整控制参数(如转速参考、断点设置),配置密钥(默认“49”)防止误操作。

环境适应性

工业级设计:具备防尘、防潮能力,适用于高温、振动等严苛环境。

静音与散热:采用高效冷却技术,支持自动调速风扇,降低噪音并保障长期运行稳定性。

典型应用场景

压缩机控制

用于往复式、螺杆式压缩机的转速调节与负载管理,优化能效与可靠性。

制冷与空调系统

监控冷机运行状态,动态调整制冷量,提升系统响应速度。

气体处理与化工生产

实时监测气体输送参数,确保安全操作与流程连续性。

注意事项

安装与维护

需按说明书操作,定期清理灰尘以避免散热失效。

电源电压需符合规格(如24 Vdc离散输入),避免过压或欠压损坏模块。

安全操作

修改配置参数前需输入密钥,防止误触导致系统异常。

在极端环境(如高湿度、腐蚀性气体)中使用时,需额外防护措施。

PS203PRESPMCPS

PS203PRESPMCPS

Product Overview

MCP-1004 is an industrial controller module developed by Compressor Controls Corporation(CCC).It is designed for compressor system control and supports real-time monitoring,multi-parameter adjustment and communication integration.This module is suitable for petroleum,chemical industry,refrigeration,gas treatment and other industrial fields,providing high reliability and environmental adaptability.

Technical parameters and functional characteristics

Core functions

Real-time monitoring:

Displays real-time parameters such as engine speed(unit:rpm),speed reference,actuator output percentage,auxiliary input voltage,remote input milliamp value and other real-time parameters.

Supports handheld devices to view dynamic data,which is easy to debug and calibration.

Multi-mode control:

It can be configured with fuel limiter,torque limiter,idle speed drop and other control logic to adapt to different working conditions.

Input/output interface

Analog input:Supports auxiliary input voltage(such as sensor signals)and remote speed setting input(milliamp signals).

Digital input/output:Including operation/stop switch status monitoring(discrete input)and actuator control output.

Actuator feedback:Provides current and position feedback(voltage readings)to ensure control accuracy.

Communication and Programmability

Protocol support:Compatible with industrial communication protocols such as Modbus,can be integrated into SCADA,PLC or HMI systems.

Configuration flexibility:Adjust control parameters(such as speed reference,breakpoint settings)through the programming menu,and configure the key(default”49″)to prevent misoperation.

Environmental adaptability

Industrial-grade design:It has dust-proof and moisture-proof capabilities,and is suitable for harsh environments such as high temperature and vibration.

Silence and heat dissipation:Use high-efficiency cooling technology,supports automatic speed regulation fans,reduce noise and ensure long-term operation stability.

Typical application scenarios

Compressor control

Used for speed adjustment and load management of reciprocating and screw compressors,optimizing energy efficiency and reliability.

Refrigeration and air conditioning systems

Monitor the operating status of the cold machine,dynamically adjust the cooling capacity,and improve the system response speed.

Gas treatment and chemical production

Monitor gas delivery parameters in real time to ensure safe operation and process continuity.

Things to note

Installation and maintenance

Follow the instructions and clean the dust regularly to avoid failure of heat dissipation.

The power supply voltage must comply with specifications(such as 24 Vdc discrete inputs)to avoid overvoltage or undervoltage damage to the module.

Safe operation

Before modifying the configuration parameters,you need to enter the key to prevent system abnormalities due to accidental touch.

Additional protection measures are required when used in extreme environments(such as high humidity,corrosive gases).