描述

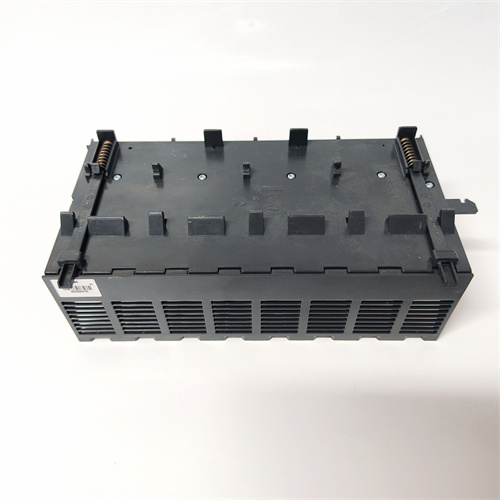

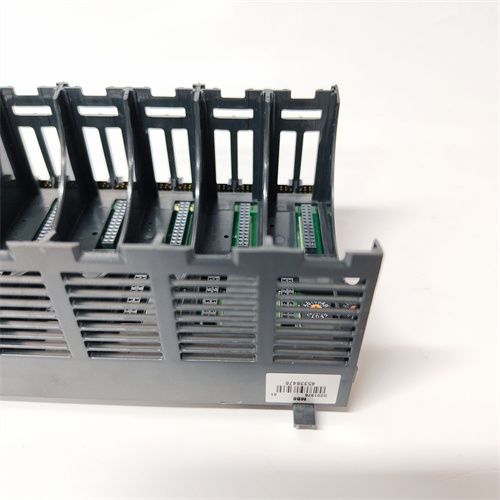

METSO D201376产品详情

METSO D201376是美卓公司生产的一款模拟输入模块,常用于工业自动化控制系统,以下为该产品的详细信息:

核心参数

品牌:METSO(美卓)

型号:D201376

类型:模拟输入模块

接口:支持多个输入通道,可连接多种传感器或设备

编程与配置:使用现有的CCW编程软件即可轻松配置

控制界面:具备图形化控制界面,操作直观

调试功能:强大的工程调试功能,支持远程调试

数据可视化:实时显示I/O模块状态、背板总线及CPU模块的运行数据,以模型化的画面呈现

通道点功能保存:支持对I/O模块的输出或输入点的配置进行保存及加载

功能特点

图形化控制界面:

用户只需点击按钮或输入数值即可控制相关I/O模块的输出,无需任何编程操作,降低了使用门槛。

支持添加对I/O模块的输出或输入点的描述,可以轻易将I/O点对应到现场设备,提高了系统的可维护性和可读性。

强大的工程调试功能:

当下装程序后,即使I/O模块未连接外围设备,也可通过工程助手直接查看程序运行情况,模拟现场工艺实际运行情况。

支持远程调试,当计算机与控制器处在同一个网段时,只需输入控制器IP地址,即可访问并调试控制器。

数据可视化与模型化:

提供直观的I/O模型视图,实时显示I/O模块状态、背板总线及CPU模块的运行数据,并以模型化的画面呈现,方便用户监控和管理。

用户友好界面:

支持自由缩放移动,操作方便,提高了用户的使用体验。

应用场景

工业自动化控制系统:

用于数据采集、信号处理和设备控制,实现工业自动化生产的智能化和高效化。

可与METSO的DCS/PLC系统无缝集成,形成完整的自动化解决方案。

过程控制与监控:

在石油、化工、电力等行业,用于监控生产过程中的各种参数,如温度、压力、流量等,确保生产过程的稳定和安全。

METSO D201376 Product Details

METSO D201376 is an analog input module produced by Metso,commonly used in industrial automation control systems.The following is the detailed information of this product:

Core parameters

Brand:METSO(Metso)

Model:D201376

Type:Analog input module

Interface:Supports multiple input channels and can connect to a variety of sensors or devices

Programming and configuration:Easily configured using the existing CCW programming software

Control interface:With a graphical control interface,intuitive operation

Debugging function:Powerful engineering debugging function,supporting remote debugging

Data visualization:Real-time display of I/O module status,backplane bus and CPU module operating data,presented in a modeled screen

Channel point function saving:Supports saving and loading the configuration of the output or input point of the I/O module

Functional features

Graphical control interface:

Users only need to click a button or enter a value to control the output of the relevant I/O module,without any programming operation,which reduces the threshold for use.

Supports adding descriptions of output or input points of I/O modules,and can easily correspond I/O points to field devices,improving the maintainability and readability of the system.

Powerful engineering debugging function:

After downloading the program,even if the I/O module is not connected to peripheral devices,you can directly view the program operation status through the engineering assistant to simulate the actual operation of the field process.

Supports remote debugging.When the computer and the controller are in the same network segment,you only need to enter the controller IP address to access and debug the controller.

Data visualization and modeling:

Provides an intuitive I/O model view,displays the I/O module status,backplane bus and CPU module operation data in real time,and presents it in a modeled screen for user monitoring and management.

User-friendly interface:

Supports free scaling and movement,easy operation,and improves the user experience.

Application scenario

Industrial automation control system:

Used for data acquisition,signal processing and equipment control to realize the intelligence and efficiency of industrial automation production.

Can be seamlessly integrated with METSO’s DCS/PLC system to form a complete automation solution.

Process control and monitoring:In the petroleum,chemical,electric power and other industries,it is used to monitor various parameters in the production process,such as temperature,pressure,flow,etc.,to ensure the stability and safety of the production process.