描述

DANAHER FSA80是丹纳赫(Danaher)旗下的一款高性能直流伺服放大器,专为工业自动化领域设计,适用于复杂控制系统中的信号放大与处理。以下是其核心产品特性的综合概述:

一、核心功能与技术参数

基本性能

-工作电压:18.5 VDC至36 VDC,支持宽范围输入,适应不同工业环境需求。

-处理速度:50 MHz,可实时响应高速控制指令,适用于高动态响应系统。

-输出频率:50 Hz,满足伺服电机的精确控制需求。

环境适应性

-温度范围:-40°C至+85°C,支持极端环境下的长期稳定运行,防护等级未明确标注但符合工业级标准。

-湿度耐受:5%至95%(非冷凝),适用于潮湿或多尘场景。

接口与结构

-模块化设计:采用控制室安装方式,尺寸为22.4 cm×39.4 cm×27.9 cm,重量1.38 kg,便于集成与维护。

-认证标准:通过UL认证,符合国际安全规范。

二、设计特点与优势

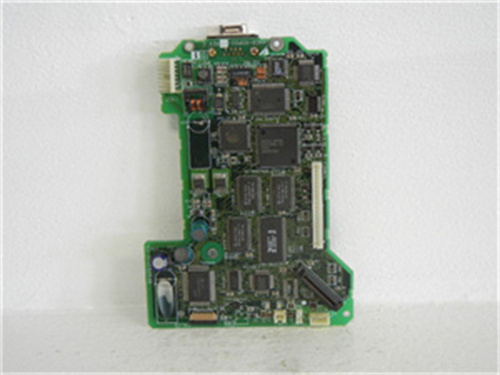

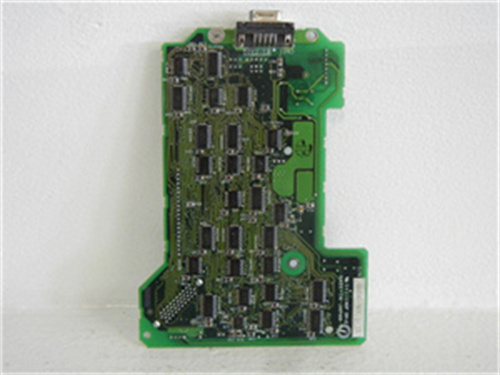

电子元件加固

-内部电子元件经过加固处理,降低静态灵敏度,减少干扰影响,并提供长期可靠性。

-需遵循严格安装流程,如检查运输包装、避免损坏及正确接线,以确保长期无故障运行。

抗干扰设计

-屏蔽与隔离:控制电缆与信号电缆需独立布线(建议间距≥8英寸),并进行屏蔽处理,减少电磁干扰。

-交叉布线规范:若需与电源或电机电缆交叉,应以90°角布置,降低耦合效应。

兼容性与扩展性

-支持与伺服驱动器(如科尔摩根系列)协同工作,适用于金属加工、液压系统控制等场景。

-可通过定制化接口适配不同品牌控制系统(如西门子、福克斯波罗)。

三、典型应用场景

流程工业自动化

-用于PID回路优化、APC(先进过程控制)及智能操作导航系统,提升装置自控率与稳定性。

-例如,在“零手动”工厂中,FSA80通过回路健康管理与参数优化,降低人工干预需求。

伺服控制系统

-驱动高精度伺服电机,实现金属切割、三维几何加工等复杂运动控制。

-额定功率覆盖300 W至50,000 W范围,适应从小型设备到大型生产线的多样化需求。

安全与应急系统

-结合冗余设计(如三重模件冗余TMR结构),应用于紧急停车(ESD)、火灾与气体检测等安全关键领域。

DANAHER FSA80 is a high-performance DC servo amplifier from Danaher,designed for the field of industrial automation and suitable for signal amplification and processing in complex control systems.The following is a comprehensive overview of its core product features:

I.Core functions and technical parameters

Basic performance

-Operating voltage:18.5 VDC to 36 VDC,supports a wide range of inputs,and adapts to the needs of different industrial environments.

-Processing speed:50 MHz,can respond to high-speed control instructions in real time,suitable for high dynamic response systems.

-Output frequency:50 Hz,to meet the precise control needs of servo motors.

Environmental adaptability

-Temperature range:-40°C to+85°C,supports long-term stable operation in extreme environments,and the protection level is not clearly marked but meets industrial standards.

-Humidity tolerance:5%to 95%(non-condensing),suitable for humid or dusty scenes.

Interface and structure

-Modular design:Control room installation,size 22.4 cm×39.4 cm×27.9 cm,weight 1.38 kg,easy integration and maintenance.

-Certification standard:UL certified,in compliance with international safety standards.

2.Design features and advantages

Electronic component reinforcement

-Internal electronic components are reinforced to reduce static sensitivity,reduce interference effects,and provide long-term reliability.

-Strict installation procedures must be followed,such as checking the transport packaging,avoiding damage,and properly wiring to ensure long-term trouble-free operation.

Anti-interference design

-Shielding and isolation:Control cables and signal cables must be independently wired(recommended spacing≥8 inches)and shielded to reduce electromagnetic interference.

-Cross wiring specifications:If it is necessary to cross with the power or motor cable,it should be arranged at a 90°angle to reduce the coupling effect.

Compatibility and scalability

-Supports working with servo drives(such as the Kollmorgen series),suitable for metal processing,hydraulic system control and other scenarios.

-Can be adapted to different brands of control systems(such as Siemens,Foxboro)through customized interfaces.

3.Typical application scenarios

Process industry automation

-Used for PID loop optimization,APC(advanced process control)and intelligent operation navigation system to improve the automatic control rate and stability of the device.

-For example,in a”zero manual”factory,FSA80 reduces the need for manual intervention through loop health management and parameter optimization.

Servo control system

-Drive high-precision servo motors to achieve complex motion control such as metal cutting and three-dimensional geometric processing.

-Rated power covers the range of 300 W to 50,000 W,adapting to the diverse needs from small equipment to large production lines.

Safety and emergency system

-Combined with redundant design(such as triple module redundant TMR structure),it is applied to safety-critical areas such as emergency shutdown(ESD),fire and gas detection.