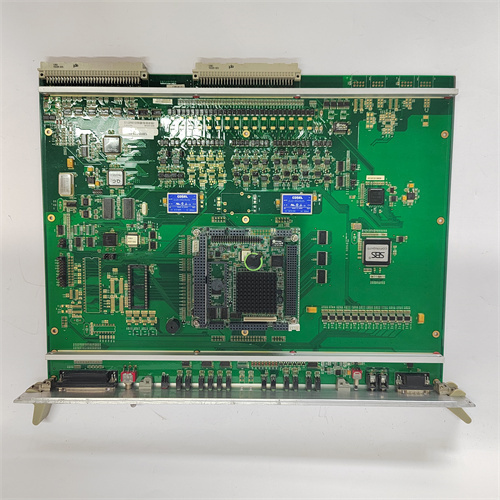

描述

DDK NFT-401RM1A-S是一款高性能扭矩转换器,专为工业应用设计,具备高扭矩能力、精确转换效率及耐用性,适用于多种复杂机械系统。以下是其核心功能与技术特点的综合解析:

一、核心功能与技术参数

高扭矩转换能力

-最大扭矩:39.2 Nm

-最大转速:250 rpm

-重量:2.1 kg

-通过紧凑型设计实现高效扭矩传输,适用于空间受限的工业场景。

精确控制与动态响应

-集成高速阻尼器,可抑制转速超过1000 rpm时的超调现象,确保平稳运行。

-支持多单元高级通信功能,数据处理速度比旧型号提升3倍,与以太网速度相当。

耐用性与可靠性

-耐用结构设计,适用于长期高强度工况,如汽车制造、包装机械及输送系统。

-支持模块化扩展,兼容DDK控制器系列(如SAN4-24),便于系统集成。

二、应用场景

工业机械

-包装机械:精准控制传送带或分拣系统的扭矩输出。

-汽车制造:用于装配线螺栓拧紧、机器人关节动力传输。

智能制造

-半导体行业:协作机器人(Cobots)、AGV/AMR动力分配。

-实验室自动化:精密设备运动控制。

能源与化工

-燃气轮机保护装置:动态扭矩调节与过载保护。

三、设计特点

模块化与兼容性

-支持Profi总线、CC链路、以太网等通信协议,可无缝对接主流PLC及DCS系统。

-控制模块灵活扩展,适应不同规模的自动化需求。

维护便捷性

-前面板状态指示灯实时显示运行状态,支持热插拔维护。

-选配CF存储卡模块,可离线存储大量数据。

智能化功能

-内置自动调谐与步进器功能,简化伺服系统调试。

-智能诊断算法可预测潜在故障,减少停机时间。

DDK NFT-401RM1A-S is a high-performance torque converter designed for industrial applications.It has high torque capacity,precise conversion efficiency and durability,and is suitable for a variety of complex mechanical systems.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and technical parameters

High torque conversion capability

-Maximum torque:39.2 Nm

-Maximum speed:250 rpm

-Weight:2.1 kg

-Efficient torque transmission through compact design,suitable for industrial scenarios with limited space.

Precise control and dynamic response

-Integrated high-speed damper can suppress overshoot when the speed exceeds 1000 rpm to ensure smooth operation.

-Support multi-unit advanced communication functions,and the data processing speed is 3 times faster than the old model,which is equivalent to Ethernet speed.

Durability and reliability

-Durable structural design,suitable for long-term high-intensity working conditions,such as automotive manufacturing,packaging machinery and conveying systems.

-Support modular expansion,compatible with DDK controller series(such as SAN4-24),easy system integration.

2.Application scenarios

Industrial machinery

-Packaging machinery:Precisely control the torque output of conveyor belts or sorting systems.

-Automobile manufacturing:used for assembly line bolt tightening and robot joint power transmission.

Intelligent manufacturing

-Semiconductor industry:collaborative robots(Cobots),AGV/AMR power distribution.

-Laboratory automation:precision equipment motion control.

Energy and chemical industry

-Gas turbine protection device:dynamic torque regulation and overload protection.

3.Design features

Modularity and compatibility

-Supports communication protocols such as Profi bus,CC link,Ethernet,etc.,and can seamlessly connect to mainstream PLC and DCS systems.

-Flexible expansion of control modules to meet automation needs of different scales.

Maintenance convenience

-The front panel status indicator displays the operating status in real time and supports hot-swap maintenance.

-Optional CF memory card module can store large amounts of data offline.

Intelligent functions

-Built-in automatic tuning and stepper functions to simplify servo system debugging.

-Intelligent diagnostic algorithms can predict potential failures and reduce downtime.