描述

产品简要说明

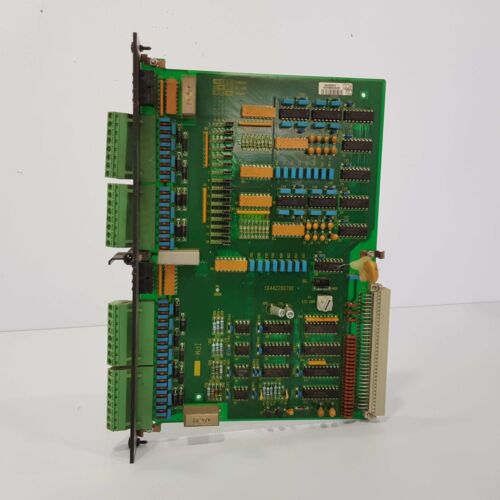

IPM-1是DEIF推出的高性能工业驱动器模块,专为复杂自动化控制系统设计。其核心特性包括:

冗余架构:支持三重模件冗余(TMR)容错控制

开放协议:兼容EtherCAT、PROFINET等工业总线

环境适应性:通过UL认证(宽温/-40°C可选)

产品详细说明

1.模块化系统架构

硬件设计

结构形式:模块化堆叠设计(DIN导轨安装)

电源配置:双电源冗余输入(220V/110V自适应)

通信接口:

Ethernet×2(主备切换)

CANopen从站(支持PDO/RPDO映射)

软件特性

编程环境:兼容IEC 61131-3标准(支持ST/LD/FBD语言)

诊断功能:

实时监测I/O状态(异常触发SOE事件)

存储历史故障代码(支持USB导出)

2.核心控制逻辑

冗余容错

TMR架构:

三重处理器同步运算(表决机制确保零单点故障)

同步精度:

多节点时间同步误差<50μs(IEEE 1588支持)

驱动性能

输出类型:

PWM脉冲宽度调制(频率范围1-10kHz可设)

负载能力:

最大驱动3kW感应电机(支持矢量控制算法)

3.行业适配方案

风电场应用:

并网逆变器同步控制(支持孤岛检测)

化工厂集成:

DAQ数据采集+PLC逻辑联动(Modbus TCP转换)

Product brief description

IPM-1 is a high-performance industrial drive module launched by DEIF,designed for complex automation control systems.Its core features include:

Redundant architecture:Supports triple module redundancy(TMR)fault-tolerant control

Open protocol:compatible with industrial buses such as EtherCAT and PROFINET

Environmental adaptability:UL certified(optional for wide temperature/-40°C)

Product details

1.Modular system architecture

Hardware design

Structural form:modular stacking design(DIN rail installation)

Power supply configuration:Dual power supply redundant input(220V/110V adaptation)

Communication interface:

Ethernet×2(main-stop switching)

CANopen slave(supports PDO/RPDO mapping)

Software Features

Programming environment:compatible with IEC 61131-3 standard(supports ST/LD/FBD language)

Diagnostic function:

Real-time monitoring of I/O status(exception triggers SOE events)

Store historical fault code(supports USB export)

2.Core control logic

Redundant fault tolerance

TMR architecture:

Triple processor synchronous operation(voting mechanism ensures zero single point failure)

Synchronization accuracy:

Multi-node time synchronization error<50μs(supported by IEEE 1588)

Driver performance

Output type:

PWM pulse width modulation(frequency range 1-10kHz can be set)

Load capacity:

Maximum drive 3kW induction motor(supports vector control algorithm)

3.Industry adaptation plan

Wind farm applications:

Grid-connected inverter synchronization control(supports island detection)

Chemical plant integration:

DAQ data acquisition+PLC logic linkage(Modbus TCP conversion)