描述

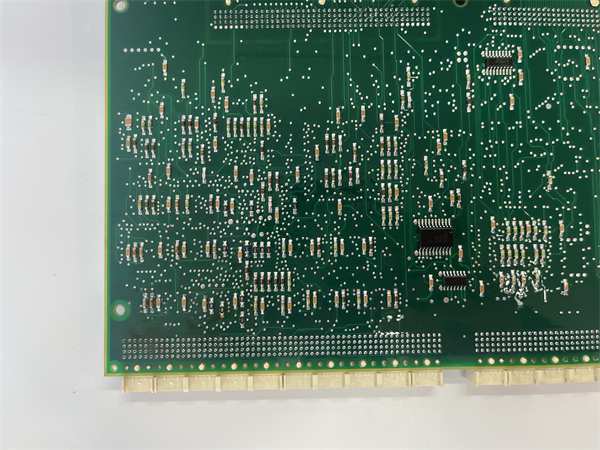

DEIF MTR-3F-215是一款专为工业自动化系统设计的模块化控制器,融合了高性能处理能力与灵活扩展特性,适用于复杂工业环境中的数据采集、逻辑控制与设备互联。以下是其核心功能与技术特点的综合概述:

一、产品定位

MTR-3F-215以模块化架构为核心,支持分布式控制与集中管理,适用于电力、机械、化工等领域的自动化系统,尤其在需要高可靠性与实时响应的场景中表现突出。

二、核心功能模块

电源模块

-提供24V直流工作电源,兼容交流220V/110V输入,支持模块化安装或集成设计,确保系统稳定供电。

I/O模块

-支持数字量与模拟量输入/输出,点数可根据需求灵活扩展,适用于传感器信号采集、执行器控制及复杂设备交互。

底板与总线接口

-集成总线通信协议(如Modbus、CANopen),支持多模块级联,实现数据高效传输与系统级联扩展。

三、技术特点

模块化设计

-支持独立更换或扩展功能模块(如电源、I/O、通信接口),便于系统升级与维护。

高可靠性

-工业级防护标准,适应极端温度与电磁干扰环境,关键模块支持冗余配置,提升系统可用性。

智能控制

-集成微处理器,支持逻辑运算、定时计数及PID调节,满足复杂工艺控制需求。

四、应用场景

工业自动化

-机床控制、机器人运动轨迹规划、生产线监控等。

电力系统

-变电站远程监控、配电网络故障诊断与保护逻辑执行。

能源管理

-新能源设备(如光伏逆变器)数据采集与并网控制。

五、技术优势

兼容性:支持主流工业协议,可无缝集成于西门子、罗克韦尔等系统生态。

扩展性:最大支持上百个I/O点数扩展,适配从小型设备到大型系统的多样化需求。

易用性:提供图形化编程工具,简化逻辑开发流程,降低运维成本。

LDMTR-01 63940135F

LDMTR-01 63940135F

.DEIF MTR-3F-215 is a modular controller designed for industrial automation systems.It combines high-performance processing capabilities with flexible expansion features and is suitable for data acquisition,logic control and equipment interconnection in complex industrial environments.The following is a comprehensive overview of its core functions and technical features:

I.Product positioning

MTR-3F-215 is based on a modular architecture and supports distributed control and centralized management.It is suitable for automation systems in the fields of power,machinery,chemical industry,etc.,especially in scenarios that require high reliability and real-time response.

II.Core functional modules

Power module

-Provides 24V DC working power supply,compatible with AC 220V/110V input,supports modular installation or integrated design,and ensures stable power supply for the system.

I/O module

-Supports digital and analog input/output,and the number of points can be flexibly expanded according to needs.It is suitable for sensor signal acquisition,actuator control and complex equipment interaction.

Backplane and bus interface

-Integrates bus communication protocols(such as Modbus,CANopen),supports multi-module cascading,and realizes efficient data transmission and system cascade expansion.

3.Technical features

Modular design

-Supports independent replacement or expansion of functional modules(such as power supply,I/O,communication interface),which is convenient for system upgrade and maintenance.

High reliability

-Industrial-grade protection standards,adapting to extreme temperature and electromagnetic interference environments,key modules support redundant configuration,and improve system availability.

Intelligent control

-Integrated microprocessor,supports logical operations,timing counting and PID adjustment,and meets the needs of complex process control.

4.Application scenarios

Industrial automation

-Machine tool control,robot motion trajectory planning,production line monitoring,etc.

Power system

-Remote monitoring of substations,distribution network fault diagnosis and protection logic execution.

Energy management

-Data acquisition and grid-connected control of new energy equipment(such as photovoltaic inverters).

5.Technical advantages

Compatibility:Supports mainstream industrial protocols and can be seamlessly integrated into system ecosystems such as Siemens and Rockwell.

Scalability:Supports up to hundreds of I/O point expansions,adapting to the diverse needs from small equipment to large systems.

Ease of use:Provides graphical programming tools to simplify the logic development process and reduce operation and maintenance costs.