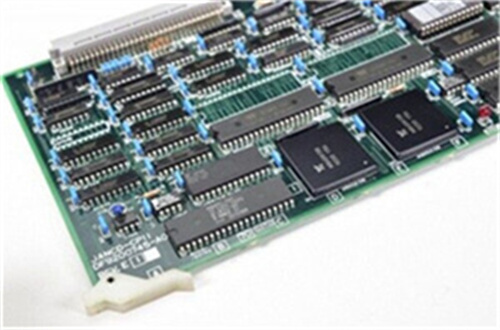

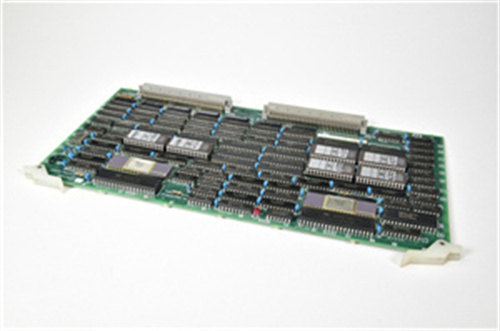

描述

DEIF SCM-1是丹麦DEIF公司开发的多功能模块化设备,广泛应用于电力系统、工业自动化及能源管理等领域。根据其功能不同,SCM-1可分为测量模块、通信模块、控制模块等类型,以下是其核心功能与技术特性的综合概述:

一、测量模块(Surge Current Monitor 1)

核心功能

-电流监测:专为检测电流突波(如浪涌电流)设计,用于电力系统中发电机保护和过载预警。

-参数测量:支持电压、电流、频率、功率因数等电气参数的高精度测量,确保电力系统运行在安全范围内。

-数据记录与报警:记录历史数据并触发阈值报警,辅助故障诊断与系统优化。

-通信接口:支持RS-232、RS-485等协议,可集成至监控系统或数据记录设备。

应用场景

-发电机组保护、微电网系统、工业配电网络。

二、通信模块

核心功能

-协议转换:支持Modbus RTU/TCP、CANbus等工业协议,实现不同设备间的无缝通信。

-接口灵活:提供RS-232、RS-485、Ethernet等接口,适配多种工业环境。

-数据处理:具备预处理与协议转换能力,减轻上位机负担,提升传输效率。

-工业级设计:抗震动、抗干扰,适用于严苛环境。

应用场景

-发电机组控制、电网自动化、楼宇自动化、船舶动力系统。

三、控制模块

核心功能

-精密控制:集成电机、传感器与执行器的控制与监测,支持PID算法及多协议通信。

-远程管理:通过上位机实现参数配置、固件升级与状态监控。

-多接口支持:提供多种输入/输出接口,兼容工业自动化系统(如PLC、DCS)。

应用场景

-电机控制系统、过程控制、自动化生产线。

四、同步模块

核心功能

-电源同步:实现发电机组与主电源的精确同步,优化负载分配与电力传输效率。

-多通道测量:同时监测多个电源的电压、电流参数,确保系统稳定性。

-工业级可靠性:适用于发电厂、变电站等关键基础设施。

DEIF SCM-1 is a multifunctional modular device developed by DEIF of Denmark.It is widely used in power systems,industrial automation and energy management.According to its functions,SCM-1 can be divided into measurement module,communication module,control module and other types.The following is a comprehensive overview of its core functions and technical characteristics:

I.Measurement module(Surge Current Monitor 1)

Core functions

-Current monitoring:Designed for detecting current surges(such as surge current)for generator protection and overload warning in power systems.

-Parameter measurement:Supports high-precision measurement of electrical parameters such as voltage,current,frequency,and power factor to ensure that the power system operates within a safe range.

-Data recording and alarm:Record historical data and trigger threshold alarms to assist fault diagnosis and system optimization.

-Communication interface:Supports RS-232,RS-485 and other protocols,and can be integrated into monitoring systems or data recording devices.

Application scenarios

-Generator protection,microgrid systems,industrial distribution networks.

2.Communication module

Core functions

-Protocol conversion:Supports industrial protocols such as Modbus RTU/TCP,CANbus,etc.to achieve seamless communication between different devices.

-Flexible interface:Provides RS-232,RS-485,Ethernet and other interfaces,suitable for a variety of industrial environments.

-Data processing:With pre-processing and protocol conversion capabilities,it reduces the burden on the host computer and improves transmission efficiency.

-Industrial-grade design:Anti-vibration and anti-interference,suitable for harsh environments.

Application scenarios

-Generator control,power grid automation,building automation,ship power system.

3.Control module

Core functions

-Precision control:Integrated control and monitoring of motors,sensors and actuators,supporting PID algorithm and multi-protocol communication.

-Remote management:Parameter configuration,firmware upgrade and status monitoring are realized through the host computer.

-Multi-interface support:Provides a variety of input/output interfaces,compatible with industrial automation systems(such as PLC,DCS).

Application scenarios

-Motor control system,process control,automated production line.

4.Synchronization module

Core functions

-Power synchronization:Achieve precise synchronization between the generator set and the main power supply,optimize load distribution and power transmission efficiency.

-Multi-channel measurement:Simultaneously monitor the voltage and current parameters of multiple power supplies to ensure system stability.

-Industrial-grade reliability:Applicable to key infrastructure such as power plants and substations.