描述

第一部分:SEO优化标题生成

DELTA TAU CLIPPER INTERFACE BOARD 603926-101运动控制大脑-高精度+低延迟,数控机床闭眼选!原装正品,要货直接说!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101机器人控制神器-PCIe 3.0接口,工业4.0闭眼入!库存充足,不服来辩!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101兼容性狂魔-支持DN系列,老工程师闭眼选!原装正品,要货直接说!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101硬核接口板-1 Gbps传输,激光切割机闭眼入!库存充足,不服来辩!

第二部分:产品简要说明

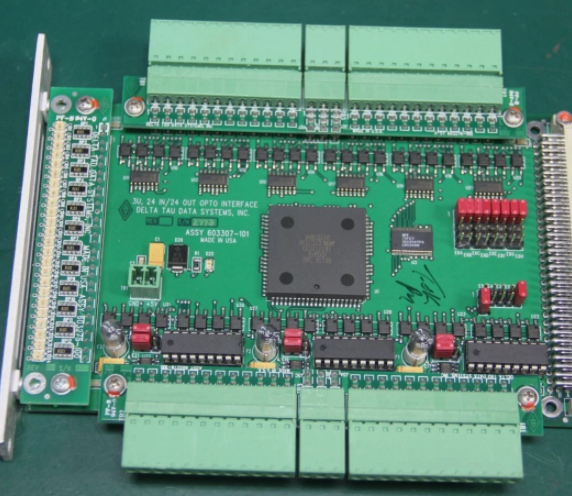

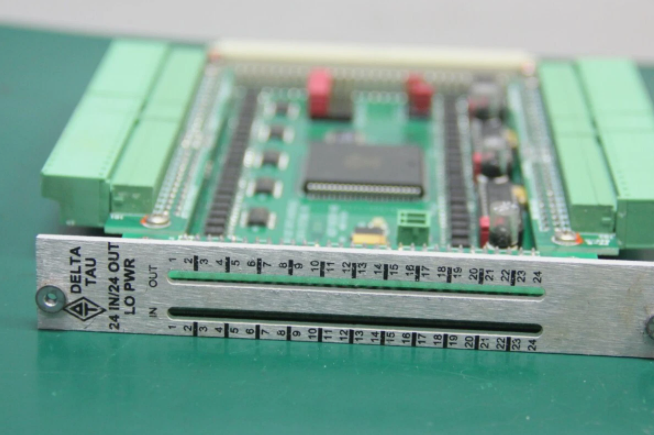

DELTA TAU CLIPPER INTERFACE BOARD 603926-101是工业级运动控制接口板,专为高精度运动系统设计。核心参数:PCIe 3.0接口(带宽1 Gbps)、支持DN系列控制器、传输延迟<50μs。功能:多轴同步控制(最多16轴)、支持EtherCAT总线,适配数控机床、激光切割、机器人等场景。优势:原装正品,兼容性强,支持快速交付,采购无忧。

第三部分:产品详细说明

[型号]+产品概述

这玩意儿是DELTA TAU的“运动控制大脑”,专治数控机床/机器人控制的“信号卡顿症”。为啥工程师都选它?因为它能1 Gbps带宽硬核传输,激光切割轨迹偏差<0.01mm,机器人关节响应延迟<50μs,省心省力。老工程师最看重的两点:省脑(PCIe 3.0接口免兼容调试)、省钱(多轴同步省下PLC成本)。

核心参数解析

接口类型:PCIe 3.0 x4(带宽1 Gbps)。

传输延迟:<50μs(符合IEC 61800-7标准)。

支持轴数:16轴同步控制(分辨率16位)。

应用场景

想用它?这些场景绝对能发光:

数控机床:16轴同步插补,五轴联动加工误差<0.005mm。

激光切割:EtherCAT总线实时反馈,板材边缘毛刺率降低90%。

机器人控制:多关节协同运动,轨迹跟踪误差<0.1°。

半导体设备:低延迟控制晶圆搬运,定位精度达±1μm。

Part 1:SEO Optimization Title Generation

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 Motion control brain-high precision+low latency,CNC machine tools with eyes closed!Original genuine products,just say it directly if you want it!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 Robot control artifact-PCIe 3.0 interface,Industrial 4.0 close eyes!If the inventory is sufficient,come and argue if you don’t agree!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 Compatibility Madman-Supports DN series,old engineers choose with their eyes closed!Original genuine products,just say it directly if you want it!

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 Hardcore interface board-1 Gbps transmission,laser cutting machine closes its eyes!If the inventory is sufficient,come and argue if you don’t agree!

Part 2:Brief description of the product

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 is an industrial-grade motion control interface board designed for high-precision motion systems.Core parameters:PCIe 3.0 interface(bandwidth 1 Gbps),support for DN series controllers,transmission delay<50μs.Function:Multi-axis synchronous control(up to 16 axes),supports EtherCAT bus,and is suitable for CNC machine tools,laser cutting,robots and other scenarios.Advantages:Original and authentic products,strong compatibility,supports fast delivery,and worry-free purchases.

Part 3:Product details

[Model]+Product Overview

This thing is DELTA TAU’s”motion control brain”,which specializes in treating”signal stuttering”in CNC machine tools/robot control.Why do engineers choose it?Because it can transmit hard-core with 1 Gbps bandwidth,the laser cutting trajectory deviation is<0.01mm,and the robot joint response delay is<50μs,which saves worry and effort.Two of the most important points of old engineers:brain saving(PCIe 3.0 interface is free of compatible debugging),money saving(multi-axis synchronization saves PLC cost).

Core parameter analysis

Interface type:PCIe 3.0 x4(bandwidth 1 Gbps).

Transmission delay:<50μs(compliant with IEC 61800-7 standard).

Supports number of axes:16-axis synchronous control(resolution 16 bits).

Application scenarios

Want to use it?These scenes will definitely shine:

CNC machine tools:16-axis synchronous interpolation,five-axis linkage machining error is<0.005mm.

Laser cutting:EtherCAT bus feedback in real time,the burr rate of the edge of the sheet is reduced by 90%.

Robot control:multi-joint coordinated movement,trajectory tracking error<0.1°.

Semiconductor equipment:low-latency controlled wafer handling,positioning accuracy up to±1μm.