描述

一、产品概述

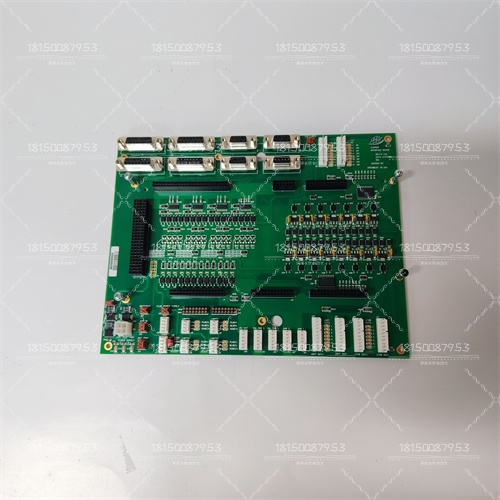

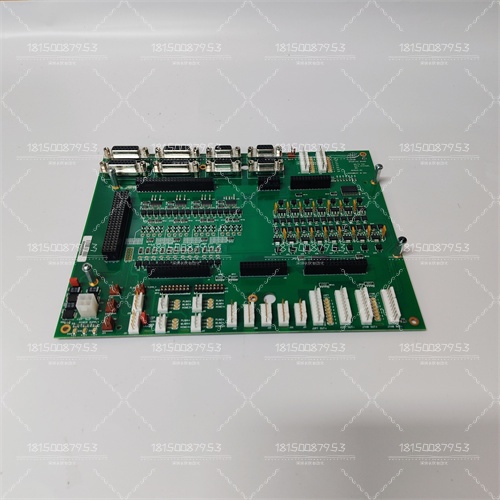

DELTA TAU CLIPPER INTERFACE BOARD 603926-101是Delta Tau Data Systems(现属Parker Hannifin旗下Motion Systems分部)生产的一款高性能运动控制接口板,专为CLIPPER系列运动控制器(如CME2、CME2-P、CME2-C等)设计。该板卡作为控制器与外部设备(如伺服驱动器、步进电机、I/O模块)之间的桥梁,支持高速通信、多轴同步控制及实时数据交换,广泛应用于工业自动化、机器人、CNC加工、半导体设备等高精度运动控制场景。

二、技术规格与功能

1.核心功能

多轴运动控制接口:

支持4-8轴同步控制(具体轴数取决于CLIPPER控制器型号),可驱动伺服电机、步进电机或直线电机。

提供PWM(脉宽调制)或模拟量(±10V)输出,兼容主流伺服驱动器(如Yaskawa、Siemens、Panasonic)。

高速通信能力:

集成SERCOS III、EtherCAT、Powerlink等实时工业以太网协议,通信周期可达1ms或更低,确保多轴同步精度。

支持RS-232/RS-485串口通信,用于参数配置或与上位机(如PLC、HMI)交互。

扩展I/O功能:

提供16-32路数字输入/输出(DI/DO),支持24V DC信号,可用于限位开关、急停按钮、传感器等连接。

可选配模拟量输入(AI)模块,用于温度、压力等模拟信号采集。

实时反馈处理:

支持编码器接口(如A/B/Z相、SSI、Hiperface),可接收电机位置、速度反馈,实现闭环控制。

部分型号集成**resolver(旋转变压器)**解码功能,适用于恶劣环境下的位置检测。

2.关键参数

参数规格

型号603926-101(CLIPPER系列专用接口板)

兼容控制器Delta Tau CLIPPER CME2/CME2-P/CME2-C等

轴数支持4-8轴(视控制器型号)

通信协议SERCOS III、EtherCAT、Powerlink、RS-232/RS-485

I/O配置16 DI/16 DO(标准),可扩展至32 DI/32 DO

模拟量输出±10V(分辨率12-16位),用于伺服驱动器速度/扭矩控制

编码器接口差分A/B/Z相(最高20MHz),支持SSI/Hiperface(需硬件选项)

工作电压24V DC(±10%),功耗<50W

环境适应性工作温度:0℃~+60℃;存储温度:-20℃~+85℃;防护等级IP20(室内安装)

尺寸标准PCI/PCIe板卡尺寸(具体取决于型号),可插入工业PC或专用控制器机箱

三、典型应用场景

工业机器人控制:

驱动6轴机械臂,实现高精度轨迹规划(如焊接、装配、喷涂)。

通过EtherCAT实时通信,确保多轴同步误差<10μs。

CNC加工中心:

控制主轴、进给轴的联动,实现复杂曲面加工(如五轴联动铣削)。

集成编码器反馈,实现位置闭环控制,精度达±0.001mm。

半导体设备:

驱动晶圆传输机器人、光刻机定位平台,满足纳米级运动控制需求。

支持SSI编码器,实现高分辨率位置检测(如1nm分辨率)。

包装机械:

控制飞剪、横切、贴标等高速运动,生产效率提升30%以上。

通过RS-485与PLC协同,实现多设备联动。

1.Product Overview

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 is a high-performance motion control interface board produced by Delta Tau Data Systems(now part of Parker Hannifin’s Motion Systems division),designed for CLIPPER series motion controllers(such as CME2,CME2-P,CME2-C,etc.).As a bridge between the controller and external devices(such as servo drives,stepper motors,I/O modules),the board supports high-speed communication,multi-axis synchronous control and real-time data exchange,and is widely used in high-precision motion control scenarios such as industrial automation,robotics,CNC processing,and semiconductor equipment.

2.Technical specifications and functions

1.Core functions

Multi-axis motion control interface:

Supports 4-8 axis synchronous control(the specific number of axes depends on the CLIPPER controller model),and can drive servo motors,stepper motors or linear motors.

Provides PWM(pulse width modulation)or analog(±10V)output,compatible with mainstream servo drives(such as Yaskawa,Siemens,Panasonic).

High-speed communication capability:

Integrates real-time industrial Ethernet protocols such as SERCOS III,EtherCAT,Powerlink,etc.,with a communication cycle of 1ms or less to ensure multi-axis synchronization accuracy.

Supports RS-232/RS-485 serial communication for parameter configuration or interaction with a host computer(such as PLC,HMI).

Extended I/O function:

Provides 16-32 digital input/output(DI/DO),supports 24V DC signals,and can be used for limit switches,emergency stop buttons,sensors,etc.

Optional analog input(AI)module for analog signal acquisition such as temperature and pressure.

Real-time feedback processing:

Supports encoder interface(such as A/B/Z phase,SSI,Hiperface),which can receive motor position and speed feedback to achieve closed-loop control.

Some models integrate**resolver**decoding function,which is suitable for position detection in harsh environments.

2.Key Parameters

Parameter Specification

Model 603926-101(CLIPPER series dedicated interface board)

Compatible controller Delta Tau CLIPPER CME2/CME2-P/CME2-C,etc.

Axis support 4-8 axes(depending on the controller model)

Communication protocol SERCOS III,EtherCAT,Powerlink,RS-232/RS-485

I/O configuration 16 DI/16 DO(standard),expandable to 32 DI/32 DO

Analog output±10V(resolution 12-16 bits),for servo drive speed/torque control

Encoder interface Differential A/B/Z phase(up to 20MHz),support SSI/Hiperface(hardware option required)

Operating voltage 24V DC(±10%),power consumption<50W

Environmental adaptability Operating temperature:0℃~+60℃;Storage temperature:-20℃~+85℃;Protection level IP20(Indoor Installation)

Dimensions Standard PCI/PCIe board size(depending on the model),can be inserted into an industrial PC or dedicated controller chassis

III.Typical Application Scenarios

Industrial Robot Control:

Drives 6-axis robotic arms to achieve high-precision trajectory planning(such as welding,assembly,spraying).

EtherCAT real-time communication ensures multi-axis synchronization error<10μs.

CNC Machining Center:

Controls the linkage of the spindle and feed axis to achieve complex surface processing(such as five-axis linkage milling).

Integrates encoder feedback to achieve position closed-loop control with an accuracy of±0.001mm.

Semiconductor Equipment:

Drives wafer transfer robots and lithography machine positioning platforms to meet nano-level motion control requirements.

Supports SSI encoders to achieve high-resolution position detection(such as 1nm resolution).

Packaging Machinery:

Controls high-speed movements such as flying shears,cross-cutting,and labeling,and increases production efficiency by more than 30%.

Cooperates with PLC through RS-485 to achieve multi-device linkage.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101