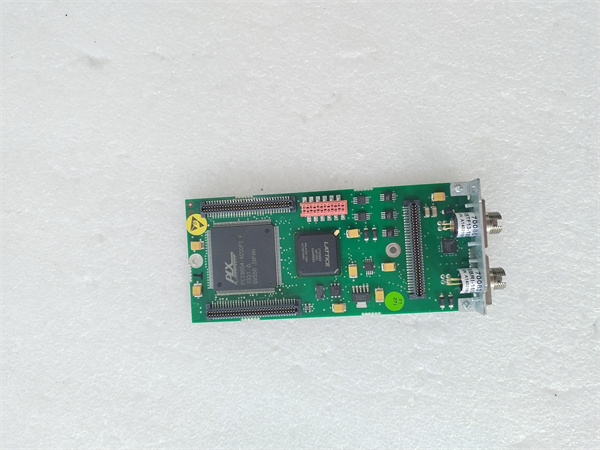

描述

DIGIFAS7105是一款高性能数字伺服放大器,专为伺服电机控制设计,广泛应用于工业自动化领域。以下是其核心功能与技术特点的综合解析:

一、核心功能定位

伺服电机控制

作为DIGIFS系列的一部分,DIGIFAS7105通过数字信号处理技术,为伺服电机提供高精度位置、速度和转矩控制,适用于对动态响应和稳定性要求严苛的应用场景。

高分辨率反馈

支持高分辨率编码器反馈,实现亚微米级定位精度,满足医疗设备、精密加工等领域的精确运动需求。

二、技术参数

型号:DIGIFAS7105

品牌:DIGIFAS

重量:7.8公斤

系列:控制系统

输入输出选项:支持多种模拟/数字信号接口,兼容主流工业协议,可灵活扩展外部设备。

三、设计特点

紧凑型设计

体积小巧,便于集成到空间受限的设备中,如机器人手臂、医疗机械等。

数字信号处理

采用先进的DSP技术,实现快速数据处理与响应,带宽性能达工业级标准。

兼容性

支持多厂商驱动器接口,可与主流伺服系统无缝协作,降低系统开发成本。

四、应用场景

机器人技术

用于六轴机器人、协作机器人等精密运动控制,实现复杂轨迹跟踪与高速响应。

工厂自动化

应用于装配线、CNC机床等设备,提升生产效率与加工精度。

医疗设备

支持医疗影像设备、手术机器人等高精度定位需求,确保操作安全与准确性。

五、优势与可靠性

高可靠性:通过工业级认证,适应高温、振动等严苛环境。

可编程性:支持用户自定义控制算法加载,满足个性化功能需求。

低功耗设计:优化能源效率,降低长期运营成本。

DIGIFAS7105 is a high-performance digital servo amplifier designed for servo motor control and widely used in industrial automation.The following is a comprehensive analysis of its core functions and technical features:

1.Core Function Positioning

Servo Motor Control

As part of the DIGIFS series,DIGIFAS7105 provides high-precision position,speed and torque control for servo motors through digital signal processing technology,suitable for application scenarios with strict requirements on dynamic response and stability.

High-resolution feedback

Supports high-resolution encoder feedback to achieve sub-micron positioning accuracy,meeting the precise motion requirements of medical equipment,precision machining and other fields.

2.Technical Parameters

Model:DIGIFAS7105

Brand:DIGIFAS

Weight:7.8 kg

Series:Control System

Input and output options:Supports a variety of analog/digital signal interfaces,compatible with mainstream industrial protocols,and can flexibly expand external devices.

3.Design Features

Compact design

Small size makes it easy to integrate into space-constrained devices such as robot arms,medical machinery,etc.

Digital Signal Processing

Adopts advanced DSP technology to achieve fast data processing and response,and bandwidth performance reaches industrial standards.

Compatibility

Supports multi-vendor driver interfaces,can work seamlessly with mainstream servo systems,and reduce system development costs.

IV.Application scenarios

Robotics

Used for precision motion control of six-axis robots,collaborative robots,etc.,to achieve complex trajectory tracking and high-speed response.

Factory automation

Applied to assembly lines,CNC machine tools and other equipment to improve production efficiency and processing accuracy.

Medical equipment

Supports high-precision positioning requirements such as medical imaging equipment and surgical robots to ensure operational safety and accuracy.

V.Advantages and reliability

High reliability:Passed industrial-grade certification,adaptable to harsh environments such as high temperature and vibration.

Programmability:Supports user-defined control algorithm loading to meet personalized functional requirements.

Low power design:Optimize energy efficiency and reduce long-term operating costs.