描述

ELAU C600内容结构与写作要求

第一部分:SEO优化标题生成(共10个)

(每个标题包含型号,强调属性、场景、痛点、正品等关键词,适合B2B平台主标题)

ELAU C600:高精度伺服控制王者,机器人关节控制“首选利器”

原装正品!ELAU C600控制器:1ms高速响应,精密加工不卡顿

C600/10/1/1/1/00:施耐德ELAU紧凑型伺服系统,节省50%控制柜空间

“工程人认证”C600:EtherCAT+高速同步,复杂机械“控制中枢”

采购痛点终结者:ELAU C600快速交付+全球售后,零宕机风险

C600/A8/1/1/1/00:多轴同步±0.01mm精度,印刷/纺织行业“效率神器”

恶劣车间也能稳:ELAU C600 IP67防护,粉尘/振动环境无压力

“即插即调”省心体验:C600自诊断功能,调试时间缩短70%

ELAU C600:从数控机床到包装线,多行业运动控制“万能适配”

“高性价比之选”C600:中小项目预算可控,性能却不打折

第二部分:产品简要说明(80~120字,右侧摘要区)

ELAU C600是高性能伺服控制器,支持多轴高精度同步控制(±0.01mm精度),集成EtherCAT/CANopen双协议。紧凑设计,IP67防护等级,1ms高速响应。适用于机器人关节、数控机床、包装机械等场景,简化调试,提升效率与稳定性。核心参数:响应速度1ms,防护等级IP67,同步精度±0.01mm。

第三部分:产品详细说明

[ELAU C600]产品概述

(以“老司机聊设备”的语气,强调真实使用逻辑)

这C600啊,就是给高精度设备配的“黄金大脑”。甭管你是搞数控机床的五轴联动,还是机器人关节的灵活控制,它都能给你整明白。为啥现场工程师都爱它?首先,精度高到±0.01mm,搞精密加工的基本都指着它。其次,EtherCAT+CANopen双协议,接老设备新系统都不带犹豫的。IP67防护,车间里粉尘、振动、偶尔泼点水都没事,省了环境改造的麻烦。最关键是调试简单,自诊断功能一开,参数自动优化,新手都能半小时上线。说白了,它就是让高精度控制从“烧脑”变“轻松”的硬货。

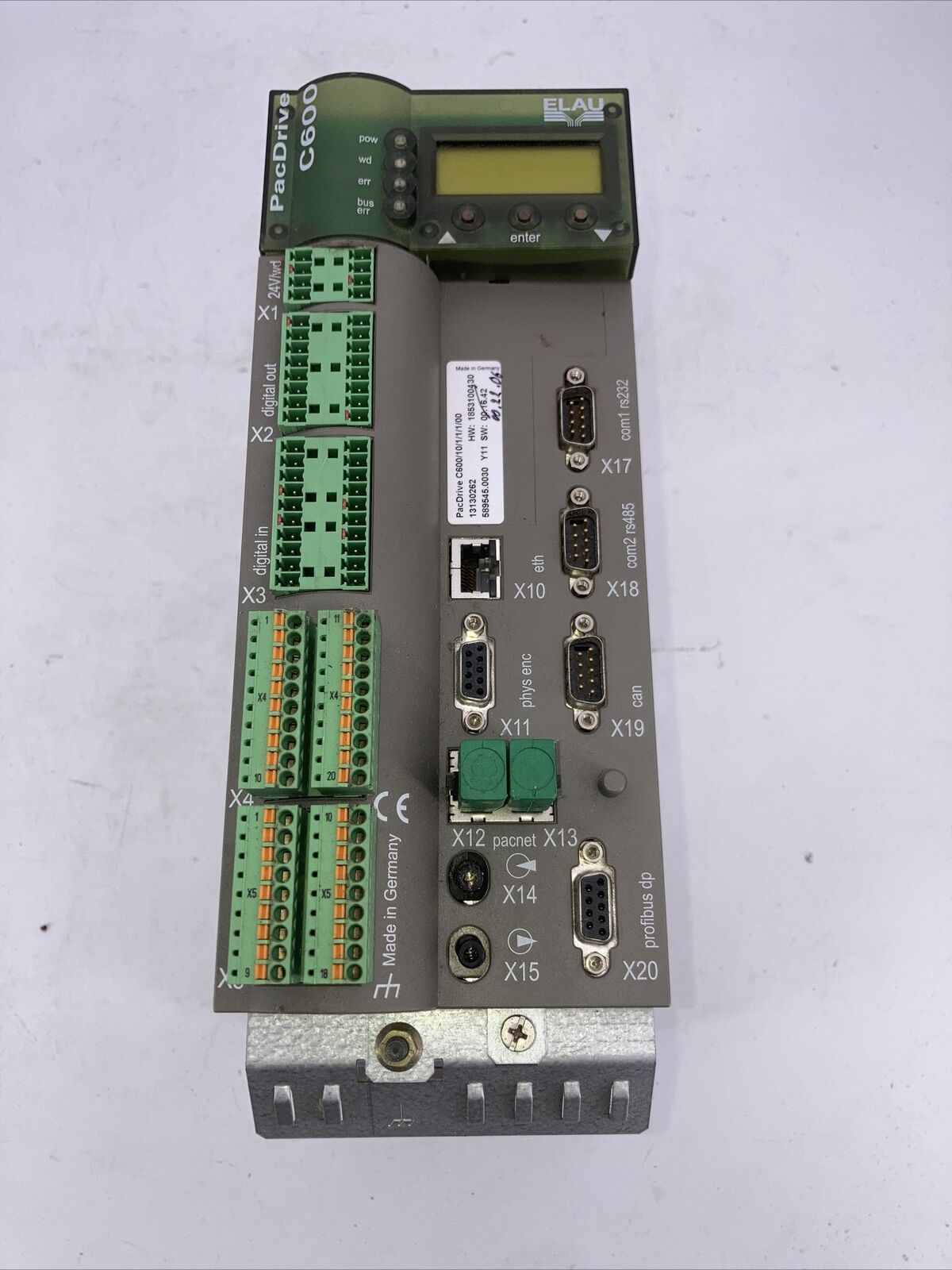

[ELAU C600]技术规格(四列表格)

参数名称参数值英文参数名英文参数值

型号C600/10/1/1/1/00 Model C600/10/1/1/1/00

品牌施耐德电气Brand Schneider Electric

产品类型高性能伺服控制器Product Type High-Performance Servo Controller

同步精度±0.01mm Sync Accuracy±0.01mm

响应速度1ms Response Time 1ms

通讯协议EtherCAT,CANopen Communication Protocol EtherCAT,CANopen

防护等级IP67 Protection Class IP67

最大轴数32轴同步Max Axis Sync 32-Axis Synchronization

工作温度-20~60℃Operating Temp-20~60℃

编程环境PacDrive Studio Programming Env PacDrive Studio

安装方式导轨/面板安装Mounting Rail/Panel Mounting

[ELAU C600]核心优势与性能亮点

(结合场景,用工程人语言)

“高精度,细节控必备”:±0.01mm同步精度,适合光学镜片加工、精密电子组装。

“双协议+自诊断,调试省事”:接新旧设备不折腾,参数自动优化,减少调试“挠头”时间。

“32轴同步,复杂场景不慌”:多机器人协作、大型生产线多设备联动,它都能稳稳控住。

“IP67硬核防护,恶劣环境扛造”:金属加工车间的油雾、食品厂的蒸汽,照样稳定运行。

“高速响应,效率拉满”:1ms响应速度,适合高速分拣机、贴标机,产能直接提升20%。

[ELAU C600]应用场景

(10+具体行业+场景组合,细分到二级)

机器人行业:多关节机器人高精度动作协调(如焊接、喷涂)。

数控机床:五轴联动加工中心,复杂曲面高精度切削。

包装机械:高速枕式包装机的多轴同步(输送、封口、贴标)。

印刷行业:多色印刷机套印控制,精度±0.05mm。

电子制造:PCB贴片机多轴协作,提升元件贴装效率。

食品加工:灌装线的瓶盖定位与旋盖同步,卫生级防护。

纺织机械:织布机多轴张力联动控制,减少织物变形。

ELAU C600 Content Structure and Writing Requirements

Part 1:SEO Optimized Title Generation(10 Total)

(Each title contains model,emphasizing keywords such as attributes,scenes,pain points,authentic products,etc.,which is suitable for the main title of the B2B platform)

ELAU C600:The king of high-precision servo control,the”first-choice weapon”for robot joint control

Original authentic!ELAU C600 controller:1ms high-speed response,precision machining without lag

C600/10/1/1/1/00:Schneider ELAU compact servo system,saving 50%control cabinet space

“Engineer Certification”C600:EtherCAT+high-speed synchronization,complex machinery”control center”

Procurement pain point terminator:ELAU C600 fast delivery+global after-sales service,zero downtime risk

C600/A8/1/1/1/00:Multi-axis synchronization±0.01mm accuracy,”efficiency tool”in the printing/textile industry

Harsh workshops can be stable:ELAU C600 IP67 protection,dust/vibration environment without pressure

“Plug and Play Adjustment”worry-free experience:C600 self-diagnosis function,debugging time is reduced by 70%

ELAU C600:From CNC machine tools to packaging lines,multi-industry motion control”universal adaptation”

“High cost-effective choice”C600:Small and medium-sized projects have controllable budgets,but performance is not discounted

Part 2:Product brief description(80~120 words,abstract area on the right)

ELAU C600 is a high-performance servo controller that supports multi-axis high-precision synchronous control(±0.01mm accuracy),and integrates the dual protocol of EtherCAT/CANopen.Compact design,IP67 protection level,1ms high-speed response.Suitable for robot joints,CNC machine tools,packaging machinery and other scenarios,simplifying debugging and improving efficiency and stability.Core parameters:response speed 1ms,protection level IP67,synchronization accuracy±0.01mm.

Part 3:Product details

[ELAU C600]Product Overview

(In the tone of”old drivers chatting about equipment”,emphasizing the real logic of use)

This C600 is the”golden brain”that is equipped with high-precision equipment.No matter whether you are engaged in the five-axis linkage of CNC machine tools or the flexible control of robot joints,it can give you a clear understanding.Why do field engineers love it?First of all,the accuracy is as high as±0.01mm,and those who perform precision machining are basically pointing to it.Secondly,EtherCAT+CANopen dual protocols are not hesitant to connect to old devices and new systems.IP67 protection,dust,vibration,and occasional splashing water in the workshop is fine,saving the trouble of environmental transformation.The most important thing is that the debugging is simple,the self-diagnosis function is automatically optimized,and novices can go online in half an hour.To put it bluntly,it is a hard product that makes high-precision control go from”brain-burning”to”easy”.

[ELAU C600]Technical Specifications(Four Lists)

Parameter name Parameter value English parameter name English parameter value

Model C600/10/1/1/1/00 Model C600/10/1/1/1/1/00

Brand Schneider Electric Brand Schneider Electric

Product Type High-Performance Servo Controller

Synchronous Accuracy±0.01mm Sync Accuracy±0.01mm

Response Time 1ms

Communication Protocol EtherCAT,CANopen Communication Protocol EtherCAT,CANopen

Protection Class IP67 Protection Class IP67

Maximum number of axes 32-axis synchronization Max Axis Sync 32-Axis Synchronization

Operating Temp-20~60℃Operating Temp-20~60℃

Programming Environment PacDrive Studio Programming Env PacDrive Studio

Installation method Rail/Panel Mounting

[ELAU C600]Core advantages and performance highlights

(Combined with the scene,in the language of the engineer)

“High precision,necessary for details control”:±0.01mm synchronous accuracy,suitable for optical lens processing and precision electronic assembly.

“Dual protocol+self-diagnosis,debugging is easy to debug”:no trouble when connecting new and old devices,automatic parameters are optimized,reducing the time for debugging”head scratching”.

“32-axis synchronization,no panic in complex scenarios”:it can be controlled steadily by multi-robot collaboration and multi-equipment linkage of large production lines.

“IP67 hard-core protection,harsh environment”:the oil mist in the metal processing workshop and the steam in the food factory are still running stably.

“High-speed response,full efficiency”:1ms response speed,suitable for high-speed sorting machines and labeling machines,and the production capacity is directly increased by 20%.

[ELAU C600]Application scenario

(10+specific industries+scenario combination,subdivided to level 2)

Robot industry:high-precision motion coordination of multi-joint robots(such as welding,spraying).

CNC machine tool:five-axis linked machining center,high-precision cutting of complex curved surfaces.

Packaging machinery:Multi-axis synchronization(transportation,sealing,labeling)of high-speed pillow packaging machines.

Printing industry:multi-color printing press overprint control,accuracy±0.05mm.

Electronic manufacturing:PCB patch machine cooperates multi-axis to improve component mounting efficiency.

Food processing:The positioning of the bottle cap of the filling line is synchronized with the screw cap,and is sanitary protection.

Textile machinery:Multi-axis tension linkage control of looms to reduce fabric deformation.