描述

ELAU MC-4/11/03/400内容结构与写作要求

第一部分:SEO优化标题生成(共10个)

(每个标题包含型号,强调属性、场景、痛点、正品等关键词,适合B2B平台主标题)

ELAU MC-4/11/03/400:施耐德旗下伺服控制“全能王”,自动化设备核心驱动神器

原装正品保障!MC-4/11/03/400伺服控制器,1.5A高响应,适配多行业场景

“工程人推荐”MC-4/11/03/400:PROFIBUS+EtherCAT双协议,设备集成不头疼

采购痛点终结者:ELAU MC-4/11/03/400快速交付,省30%调试时间

MC-4/11/03/400:重载机械“心脏”,抗干扰能力强,恶劣车间稳如老狗

ELAU MC-4/11/03/400:±0.05mm精度控制,数控机床/机器人关节“精准搭档”

“模块化设计”省心之选:MC-4/11/03/400灵活扩展,老设备升级首选

CNC加工/包装机械必看:MC-4/11/03/400 3AC 400V输入,大功率设备轻松控

ELAU MC-4/11/03/400:从单机到生产线,多轴联动“控制中枢”

“性价比之王”MC-4/11/03/400:中小项目预算可控,性能对标高端机型

第二部分:产品简要说明(80~120字,右侧摘要区)

ELAU MC-4/11/03/400是高性能伺服控制器,支持PROFIBUS、EtherCAT双协议,输入3AC 380-480V,输出1.5A,精度±0.05mm。适用于数控机床、包装机械、自动化生产线等场景,模块化设计,抗干扰能力强,调试简便。核心参数:输入电压3AC 380-480V,输出电流1.5A,精度±0.05mm。

第三部分:产品详细说明

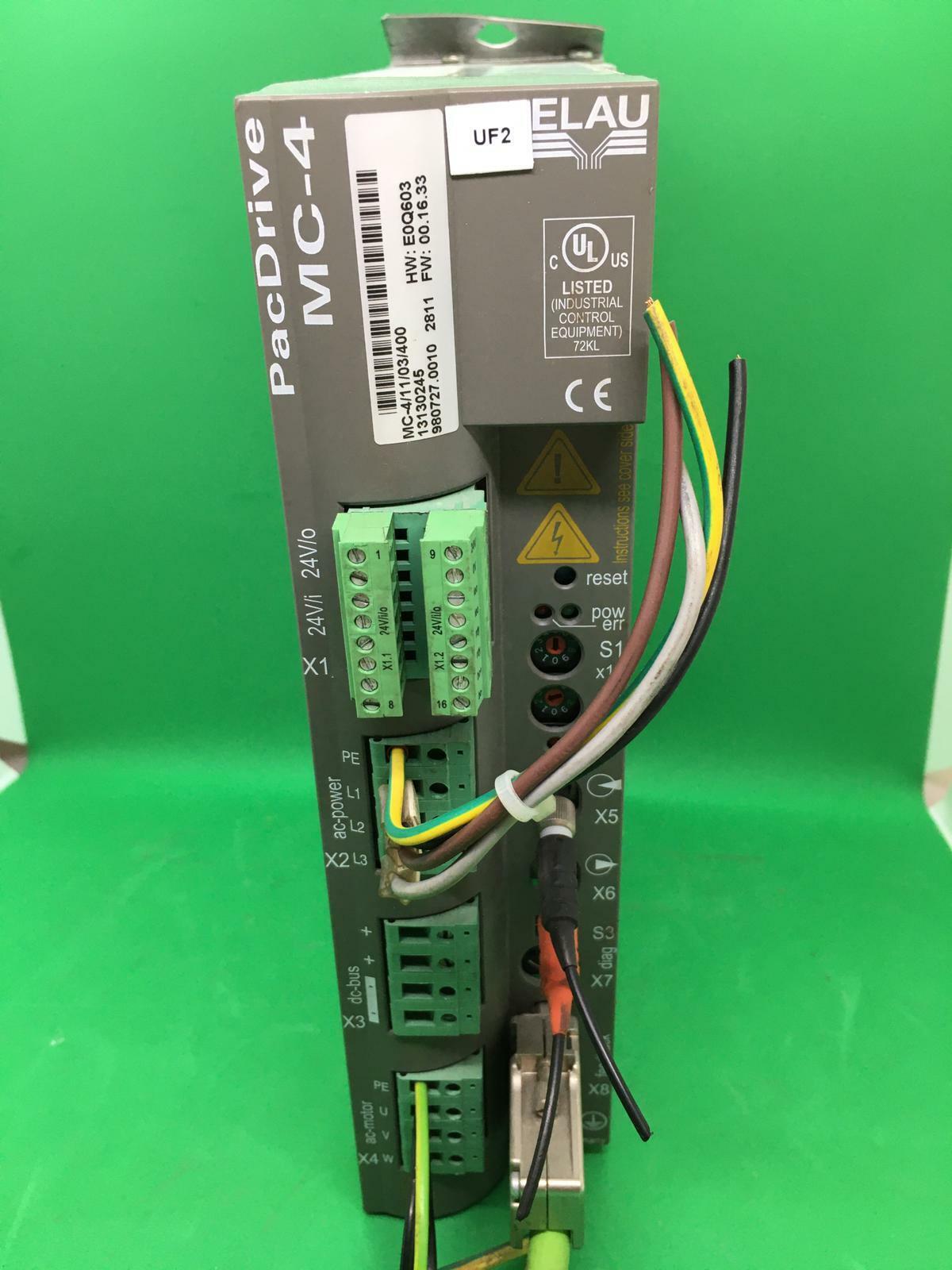

[ELAU MC-4/11/03/400]产品概述

(以“老司机聊设备”的语气,强调真实使用逻辑)

这MC-4/11/03/400啊,就是给自动化设备配的“万能心脏”。甭管你是搞机床加工的五轴联动,还是搞包装线的多轴同步,它都能给你稳稳控住。为啥现场工程师都认它?首先,PROFIBUS+EtherCAT双协议,接老系统新设备都兼容,省了通讯适配的麻烦。其次,3AC 380-480V高压输入,带大功率电机不带怂的,车间电压波动也不怕。最关键是抗干扰能力贼强,电磁环境复杂的场合照样稳。调试时参数自优化,小白也能半小时上线。说白了,它就是让复杂控制变简单的硬家伙,省事又省心。

[ELAU MC-4/11/03/400]技术规格(四列表格)

参数名称参数值英文参数名英文参数值

型号MC-4/11/03/400 Model MC-4/11/03/400

品牌施耐德电气Brand Schneider Electric

产品类型高性能伺服控制器Product Type High-Performance Servo Controller

输入电压3AC 380-480V Input Voltage 3AC 380-480V

输出电流1.5A Output Current 1.5A

通讯协议PROFIBUS,EtherCAT Communication Protocol PROFIBUS,EtherCAT

精度±0.05mm Accuracy±0.05mm

防护等级IP20 Protection Class IP20

工作温度-10~50℃Operating Temp-10~50℃

编程环境PacDrive 3 Programming Env PacDrive 3

安装方式导轨/面板安装Mounting Rail/Panel Mounting

[ELAU MC-4/11/03/400]核心优势与性能亮点

(结合场景,用工程人语言)

“双协议兼容,接啥设备都成”:PROFIBUS+EtherCAT,新旧系统无缝对接,减少兼容性烦恼。

“高压输入,大功率带得动”:3AC 380-480V适配重载设备,比如注塑机、冲压机械。

“抗干扰,车间电磁乱也不怕”:电磁兼容性设计,旁边有变频器、大功率电机照样稳定。

“调试像玩手游”:参数自优化功能,工程师少调50%时间,新手也能快速上手。

“省空间设计”:紧凑尺寸,控制柜省出1/3空间,适合改造项目。

[ELAU MC-4/11/03/400]应用场景

(10+具体行业+场景组合,细分到二级)

数控机床:三轴联动加工中心,高精度零件切削。

包装机械:高速灌装线的多轴同步(灌装、封口、贴标)。

印刷设备:胶印机套色控制,减少色差。

塑料加工:注塑机注射与模具开合同步控制。

食品生产线:烘焙机械的传送带精准定位。

纺织机械:织布机张力控制,减少布料瑕疵。

物流分拣:自动化分拣机的货物抓取与路径优化。

汽车组装:零部件输送线的多工位协作。

ELAU MC-4/11/03/400 Content structure and writing requirements

Part 1:SEO Optimized Title Generation(10 Total)

(Each title contains model,emphasizing keywords such as attributes,scenes,pain points,authentic products,etc.,which is suitable for the main title of the B2B platform)

ELAU MC-4/11/03/400:Schneider’s servo control”all-round king”is the core driving tool of automation equipment

Original authentic product guarantee!MC-4/11/03/400 servo controller,1.5A high response,adapted to multiple industry scenarios

“Recommended by engineers”MC-4/11/03/400:PROFIBUS+EtherCAT dual protocol,device integration does not cause headaches

Procurement pain point terminator:ELAU MC-4/11/03/400 fast delivery,saving 30%commissioning time

MC-4/11/03/400:Heavy-loaded machinery”heart”,strong anti-interference ability,and harsh workshops are as stable as old dogs

ELAU MC-4/11/03/400:±0.05mm precision control,”precise partner”of CNC machine tools/robot joints

“Modular Design”worry-free choice:MC-4/11/03/400 flexible expansion,first choice for upgrading old equipment

CNC processing/packaging machinery must be viewed:MC-4/11/03/400 3AC 400V input,easy to control high-power equipment

ELAU MC-4/11/03/400:From stand-alone to production line,multi-axis linkage”control center”

“King of Cost-performance”MC-4/11/03/400:Small and medium-sized projects have controllable budgets,and their performance is comparable to high-end models.

Part 2:Product brief description(80~120 words,abstract area on the right)

ELAU MC-4/11/03/400 is a high-performance servo controller that supports dual protocols of PROFIBUS and EtherCAT,input 3AC 380-480V,output 1.5A,and accuracy±0.05mm.Suitable for CNC machine tools,packaging machinery,automated production lines and other scenarios,it has a modular design,strong anti-interference ability,and easy debugging.Core parameters:Input voltage 3AC 380-480V,output current 1.5A,accuracy±0.05mm.

Part 3:Product details

[ELAU MC-4/11/03/400]Product Overview

(In the tone of”old drivers chatting about equipment”,emphasizing the real logic of use)

This MC-4/11/03/400 is the”universal heart”that is equipped with automation equipment.No matter whether you are engaged in five-axis linkage for machine tool processing or multi-axis synchronization for packaging lines,it can give you steady control.Why do field engineers recognize it?First of all,PROFIBUS+EtherCAT dual protocols are compatible with old systems and new devices,saving the hassle of communication adaptation.Secondly,3AC 380-480V high-voltage input,with high-power motors,and there is no need to worry about workshop voltage fluctuations.The most important thing is that the anti-interference ability is strong and the electromagnetic environment is still stable.The parameters are self-optimized during debugging,and Xiaobai can also be online in half an hour.To put it bluntly,it is a hard guy who makes complex control simple,which is both trouble-free and worry-free.

[ELAU MC-4/11/03/400]Technical Specifications(Four Lists)

Parameter name Parameter value English parameter name English parameter value

Model MC-4/11/03/400 Model MC-4/11/03/400

Brand Schneider Electric Brand Schneider Electric

Product Type High-Performance Servo Controller

Input Voltage 3AC 380-480V Input Voltage 3AC 380-480V

Output Current 1.5A

Communication Protocol PROFIBUS,EtherCAT Communication Protocol PROFIBUS,EtherCAT

Accuracy±0.05mm Accuracy±0.05mm

Protection Class IP20 Protection Class IP20

Operating Temp-10~50℃Operating Temp-10~50℃

Programming Environment PacDrive 3 Programming Env PacDrive 3

Installation method Rail/Panel Mounting

[ELAU MC-4/11/03/400]Core advantages and performance highlights

(Combined with the scene,in the language of the engineer)

“Dual protocol compatible,any device connected”:PROFIBUS+EtherCAT,seamless connection between new and old systems,reducing compatibility troubles.

“High voltage input,high power belt can be driven”:3AC 380-480V is adapted to heavy-load equipment,such as injection molding machines and stamping machines.

“Anti-interference,no fear of electromagnetic chaos in the workshop”:electromagnetic compatibility design,and there is still stable frequency converter and high-power motor next to it.

“Debugging is like playing mobile games”:parameter self-optimization function,engineers can adjust 50%less time,and novices can get started quickly.

“Space-saving design”:compact size,control cabinet saves 1/3 of space,suitable for renovation projects.

[ELAU MC-4/11/03/400]Application scenarios

(10+specific industries+scenario combination,subdivided to level 2)

CNC machine tool:three-axis linkage machining center,high-precision parts cutting.

Packaging machinery:multi-axis synchronization of high-speed filling lines(filling,sealing,labeling).

Printing equipment:color control for offset printing machine to reduce color aberration.

Plastic processing:Synchronous control of injection molding machine and mold opening and contract opening.

Food production line:precise positioning of conveyor belts for baking machinery.

Textile machinery:Loom tension control to reduce fabric defects.

Logistics sorting:cargo grabbing and path optimization of automated sorting machines.

Automobile assembly:multi-station collaboration of parts conveying lines.