描述

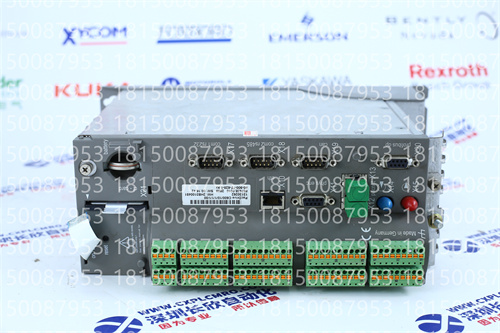

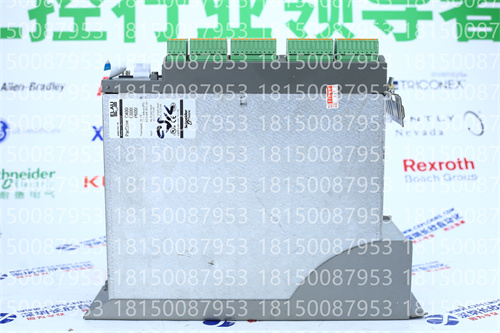

ELAU PACDrive C60010111000产品详情

ELAU PACDrive C60010111000是ELAU(现属施耐德电气旗下,专注于运动控制与自动化解决方案)推出的一款高性能PAC(Programmable Automation Controller,可编程自动化控制器),专为复杂运动控制、高速同步、多轴协调等高端自动化场景设计。该产品集成PLC逻辑控制、运动控制、HMI交互于一体,支持EtherCAT实时通信,广泛应用于包装机械、印刷设备、机器人、纺织机械等行业,是高精度、高柔性自动化系统的核心控制单元。

一、产品定位与核心功能

1.目标应用场景

包装机械:

作为立式包装机、枕式包装机、给袋式包装机的主控制器,协调送料、封口、切袋、打印等多轴同步运动,实现高速包装(每分钟1000包以上)与精准定位(±0.1mm)。

典型应用:食品、药品、日化行业的自动化包装线。

印刷设备:

用于凹版印刷机、柔版印刷机、数字印刷机的张力控制与套色系统,通过多轴闭环控制确保印刷套准精度±0.05mm,减少材料浪费。

工业机器人:

集成于6轴工业机器人、SCARA机器人的控制系统,支持逆运动学解算、轨迹规划、碰撞检测,实现高速拾放(Pick&Place)、焊接、装配等复杂任务。

纺织机械:

作为经编机、圆纬机、提花机的主控单元,协调上百个纱嘴、织针、送经的同步运动,提升织物密度与花纹精度。

2.核心功能

多轴同步运动控制:

支持最多64轴实时同步控制,通过EtherCAT总线实现纳秒级通信延迟,确保多轴运动的高协调性(如机器人关节、印刷辊筒、纺织纱嘴)。

内置电子凸轮、电子齿轮、飞剪等高级运动控制算法,简化复杂运动编程。

高性能逻辑控制:

基于IEC 61131-3标准,支持梯形图(LD)、功能块图(FBD)、结构化文本(ST)等5种编程语言,兼容传统PLC应用。

扫描周期<1ms,可实时处理高速计数、脉冲输出、PID调节等任务。

集成化设计:

融合PLC、运动控制器、HMI服务器功能于一体,减少系统组件数量,降低硬件成本与布线复杂度。

支持Web服务器功能,可通过浏览器远程监控与调试,提升维护效率。

开放性与兼容性:

支持OPC UA、Modbus TCP、Profinet等工业通信协议,可与西门子、罗克韦尔、倍福等品牌设备无缝集成。

提供C/C++、MATLAB/Simulink接口,支持自定义算法开发与仿真验证。

二、技术规格与性能参数

1.硬件参数

处理器:

Intel Atom E3800系列(四核,1.9GHz),具备低功耗(10W)与高计算性能,满足实时控制与数据处理需求。

内存与存储:

2GB DDR3L RAM,支持最大8GB扩展,确保复杂程序流畅运行。

8GB eMMC固态存储,可存储用户程序、历史数据、配方参数。

I/O接口:

本地I/O:

数字量输入:16路(24V DC,光耦隔离),支持高速计数(最高1MHz)。

数字量输出:16路(24V DC,0.5A),支持PWM输出与脉冲训练。

模拟量输入:4路(0-10V/4-20mA,12位分辨率),用于温度、压力、张力等信号采集。

模拟量输出:2路(0-10V/4-20mA),用于阀门、变频器控制。

总线接口:

2个EtherCAT主站端口,支持环形拓扑与冗余通信,确保总线故障时的系统可靠性。

1个EtherNet/IP端口,用于与HMI、SCADA系统通信。

1个USB 3.0端口,用于程序下载、日志导出。

电源与防护:

输入电压:24V DC±20%,功耗<50W,适应工业现场电源波动。

防护等级****:IP20,需安装于控制柜内,避免灰尘与液体直接接触。

工作温度:0℃至+55℃(存储温度:-25℃至+70℃),适应常规工业环境。

2.软件参数

操作系统:

ELAU PACDrive OS(基于Linux实时内核),提供确定性任务调度与低延迟通信。

编程软件:

Schneider Electric SoMachine Motion(原ELAU PacDrive SMC),支持离线仿真、在线调试、远程诊断。

兼容CODESYS 3.5,可导入现有CODESYS程序,降低迁移成本。

运动控制库:

内置电子凸轮、电子齿轮、飞剪、同步跟踪等200+个功能块,支持拖拽式编程,缩短开发周期。

安全功能:

支持SIL2/PLd安全等级,集成安全扭矩关闭(STO)、安全限速(SSL)等功能,符合IEC 61508标准。

三、产品特点与优势

1.高性能与高实时性

EtherCAT总线优势:

采用EtherCAT分布式时钟(DC)技术,实现各从站时钟同步误差<1μs,确保多轴运动的高协调性。

支持热插拔与拓扑重构,可在运行中添加/移除从站设备,提升系统灵活性。

硬实时任务调度:

通过专用运动控制内核,将运动任务优先级置于逻辑任务之上,避免逻辑运算占用运动控制资源,确保轨迹精度与响应速度。

2.集成化与易用性

三合一设计:

融合PLC、运动控制器、HMI服务器功能,减少系统组件数量,降低硬件成本与布线复杂度。

例如:传统方案需PLC+运动控制器+HMI触摸屏,而C60010111000仅需1台控制器+1块触摸屏即可实现相同功能。

图形化编程工具:

提供运动控制向导,用户可通过拖拽功能块、配置参数快速生成凸轮表、电子齿轮比,无需手动编写复杂代码。

支持3D运动仿真,可在虚拟环境中验证机械动作,减少现场调试时间。

.ELAU PACDrive C60010111000 Product Details

The ELAU PACDrive C60010111000 is a high-performance PAC(Programmable Automation Controller)from ELAU(now a subsidiary of Schneider Electric,specializing in motion control and automation solutions).It is designed for high-end automation scenarios such as complex motion control,high-speed synchronization,and multi-axis coordination.This product integrates PLC logic control,motion control,and HMI interaction,supporting EtherCAT real-time communication.It is widely used in industries such as packaging machinery,printing equipment,robotics,and textile machinery,serving as the core control unit for high-precision and highly flexible automation systems.

I.Product Positioning and Core Functions

1.Target Application Scenarios

Packaging Machinery:

Serving as the main controller for vertical packaging machines,pillow packaging machines,and bag-feeding packaging machines,it coordinates multi-axis synchronized motion,including feeding,sealing,bag cutting,and printing,achieving high-speed packaging(over 1,000 packages per minute)and precise positioning(±0.1mm).Typical Applications:Automated packaging lines in the food,pharmaceutical,and daily chemical industries.

Printing Equipment:

Used in the tension control and color registration systems of gravure,flexographic,and digital printing presses,multi-axis closed-loop control ensures print registration accuracy of±0.05mm,reducing material waste.

Industrial Robotics:

Integrated into the control systems of 6-axis industrial robots and SCARA robots,it supports inverse kinematics,trajectory planning,and collision detection,enabling complex tasks such as high-speed pick&place,welding,and assembly.

Textile Machinery:

Serving as the main control unit for warp knitting machines,circular knitting machines,and jacquard machines,it coordinates the synchronized motion of hundreds of yarn feeders,needles,and warp let-offs,improving fabric density and pattern accuracy.

2.Core Functions:

Multi-Axis Synchronous Motion Control:

Supports real-time synchronized control of up to 64 axes,achieving nanosecond-level communication latency via the EtherCAT bus,ensuring highly coordinated multi-axis motion(e.g.,robot joints,printing rollers,and textile yarn feeders).Built-in advanced motion control algorithms such as electronic cam,electronic gear,and flying shear simplify complex motion programming.

High-Performance Logic Control:

Based on the IEC 61131-3 standard,it supports five programming languages,including ladder diagram(LD),function block diagram(FBD),and structured text(ST),and is compatible with traditional PLC applications.

With a scan cycle of<1ms,it can handle tasks such as high-speed counting,pulse output,and PID control in real time.

Integrated Design:

Combining the functions of a PLC,motion controller,and HMI server,it reduces the number of system components,hardware costs,and wiring complexity.

Web server functionality enables remote monitoring and debugging via a browser,improving maintenance efficiency.

Openness and Compatibility:

Support for industrial communication protocols such as OPC UA,Modbus TCP,and Profinet enables seamless integration with equipment from brands such as Siemens,Rockwell,and Beckhoff.

Providing C/C++and MATLAB/Simulink interfaces enables custom algorithm development and simulation verification.II.Technical Specifications and Performance Parameters

1.Hardware Parameters

Processor:

Intel Atom E3800 series(quad-core,1.9GHz),featuring low power consumption(10W)and high computing performance,meeting real-time control and data processing requirements.

Memory and Storage:

2GB DDR3L RAM,expandable up to 8GB,ensuring smooth operation of complex programs.

8GB eMMC solid-state storage for storing user programs,historical data,and recipe parameters.

I/O Interfaces:

Local I/O:

Digital Inputs:16 channels(24V DC,optocoupler isolation),supporting high-speed counting(up to 1MHz).

Digital Outputs:16 channels(24V DC,0.5A),supporting PWM output and pulse training.

Analog Inputs:4 channels(0-10V/4-20mA,12-bit resolution),for acquiring signals such as temperature,pressure,and tension.Analog Output:2 channels(0-10V/4-20mA)for valve and inverter control.

Bus Interface:

2 EtherCAT master ports,supporting ring topology and redundant communication,ensuring system reliability in the event of bus failures.

1 EtherNet/IP port for communication with HMI and SCADA systems.

1 USB 3.0 port for program downloads and log exports.

Power Supply and Protection:

Input voltage:24V DC±20%,power consumption<50W,adaptable to power fluctuations in industrial sites.

Protection Rating****:IP20.Requires installation in a control cabinet to protect from dust and liquids.

Operating Temperature:0°C to+55°C(Storage Temperature:-25°C to+70°C),suitable for typical industrial environments.

2.Software Parameters

Operating System:

ELAU PACDrive OS(based on the Linux real-time kernel)provides deterministic task scheduling and low-latency communication.Programming Software:

Schneider Electric SoMachine Motion(formerly ELAU PacDrive SMC),supports offline simulation,online debugging,and remote diagnostics.

Compatible with CODESYS 3.5,existing CODESYS programs can be imported,reducing migration costs.

Motion Control Library:

Over 200 built-in function blocks,including electronic cams,electronic gears,flying shears,and synchronous tracking,support drag-and-drop programming,shortening development cycles.

Safety Functions:

Supports SIL2/PLd safety levels,integrates Safe Torque Off(STO)and Safely Limited Speed(SSL),and complies with IEC 61508 standards.

III.Product Features and Advantages

1.High Performance and Real-Time Performance

EtherCAT Bus Advantages:

Utilizing EtherCAT Distributed Clock(DC)technology,slave clock synchronization error is less than 1μs,ensuring highly coordinated multi-axis motion.

Supports hot-swapping and topology reconfiguration,allowing slave devices to be added/removed during operation,enhancing system flexibility.Hard Real-Time Task Scheduling:

A dedicated motion control core prioritizes motion tasks over logic tasks,preventing logic operations from occupying motion control resources and ensuring trajectory accuracy and responsiveness.

2.Integration and Ease of Use

Three-in-One Design:

Combining the functions of a PLC,motion controller,and HMI server,it reduces the number of system components,hardware costs,and wiring complexity.

For example,while traditional solutions require a PLC,motion controller,and HMI touch screen,the C60010111000 only requires one controller and one touch screen to achieve the same functionality.

Graphical Programming Tool:

Provides a motion control wizard that allows users to quickly generate cam tables and electronic gear ratios by dragging and dropping function blocks and configuring parameters,eliminating the need for complex manual code.

Support for 3D motion simulation allows for verification of mechanical motion in a virtual environment,reducing on-site debugging time.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101