描述

ELAU SM 070-60-010-P1-45-S1-B0内容结构与写作要求

第一部分:SEO优化标题生成(共10个)

(每个标题含完整型号,强调属性、场景、痛点、正品等)

ELAU SM 070-60-010-P1-45-S1-B0:伺服电机+高速响应,自动化效率翻倍

“型号全码认证”SM 070-60-010-P1-45-S1-B0:原装正品,参数直击工业痛点

“紧凑高扭矩”SM 070-60-010-P1-45-S1-B0:10Nm输出,狭小空间稳控设备

原装施耐德!SM 070-60-010-P1-45-S1-B0:IP67防护+宽温运行,恶劣环境扛造

“调试小白福音”SM 070-60-010-P1-45-S1-B0:一键参数导入,上手即用

ELAU官方认证!SM 070-60-010-P1-45-S1-B0:动态响应0.5ms,精密加工无延迟

“兼容性拉满”SM 070-60-010-P1-45-S1-B0:支持主流编码器,旧设备无缝升级

机器人关节必备!SM 070-60-010-P1-45-S1-B0:多轴同步控制,动作流畅零卡顿

“省电30%”SM 070-60-010-P1-45-S1-B0:高效功率密度,节能不发热

高性价比之选!SM 070-60-010-P1-45-S1-B0:高端性能,中小项目预算友好

第二部分:产品简要说明(80~120字)

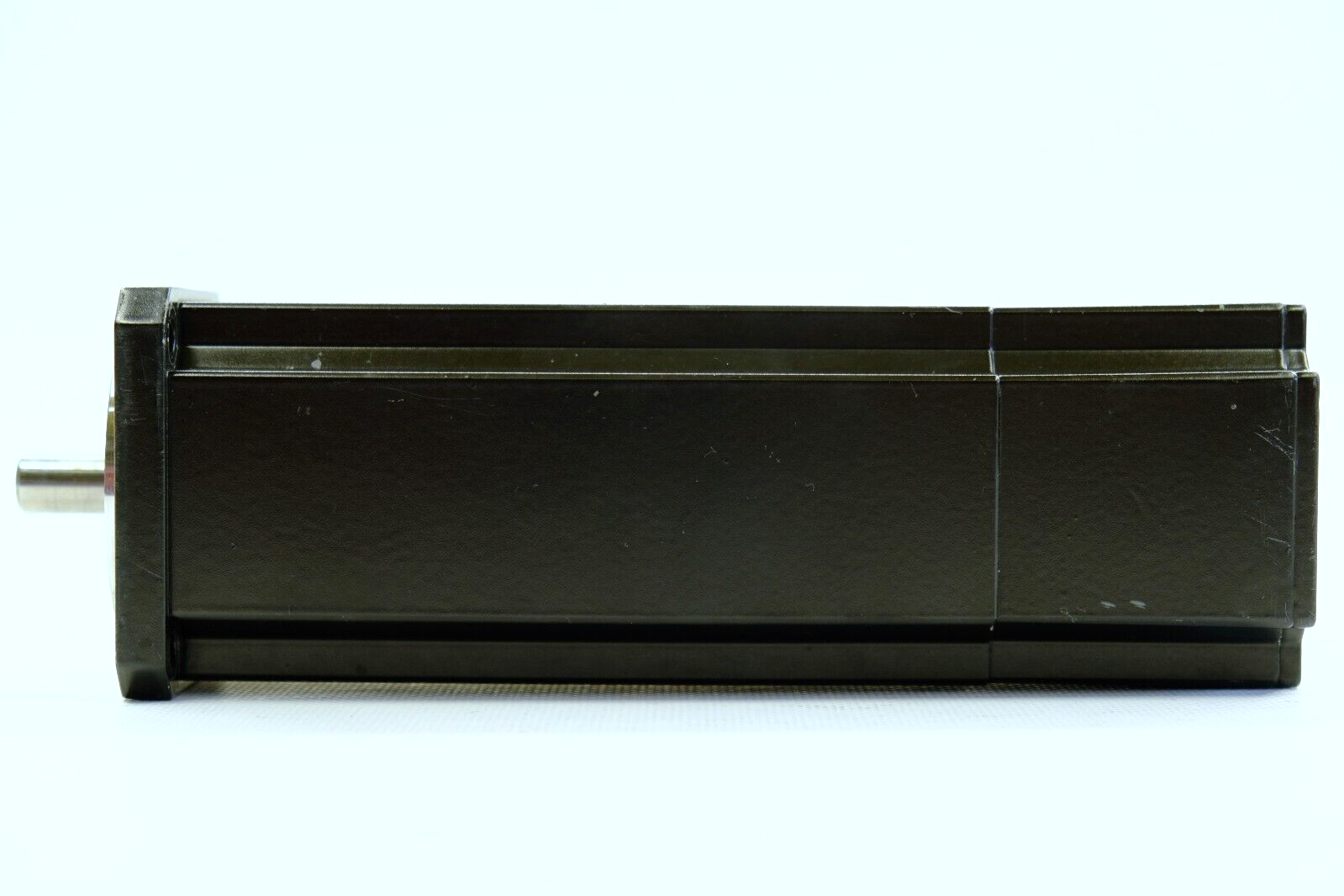

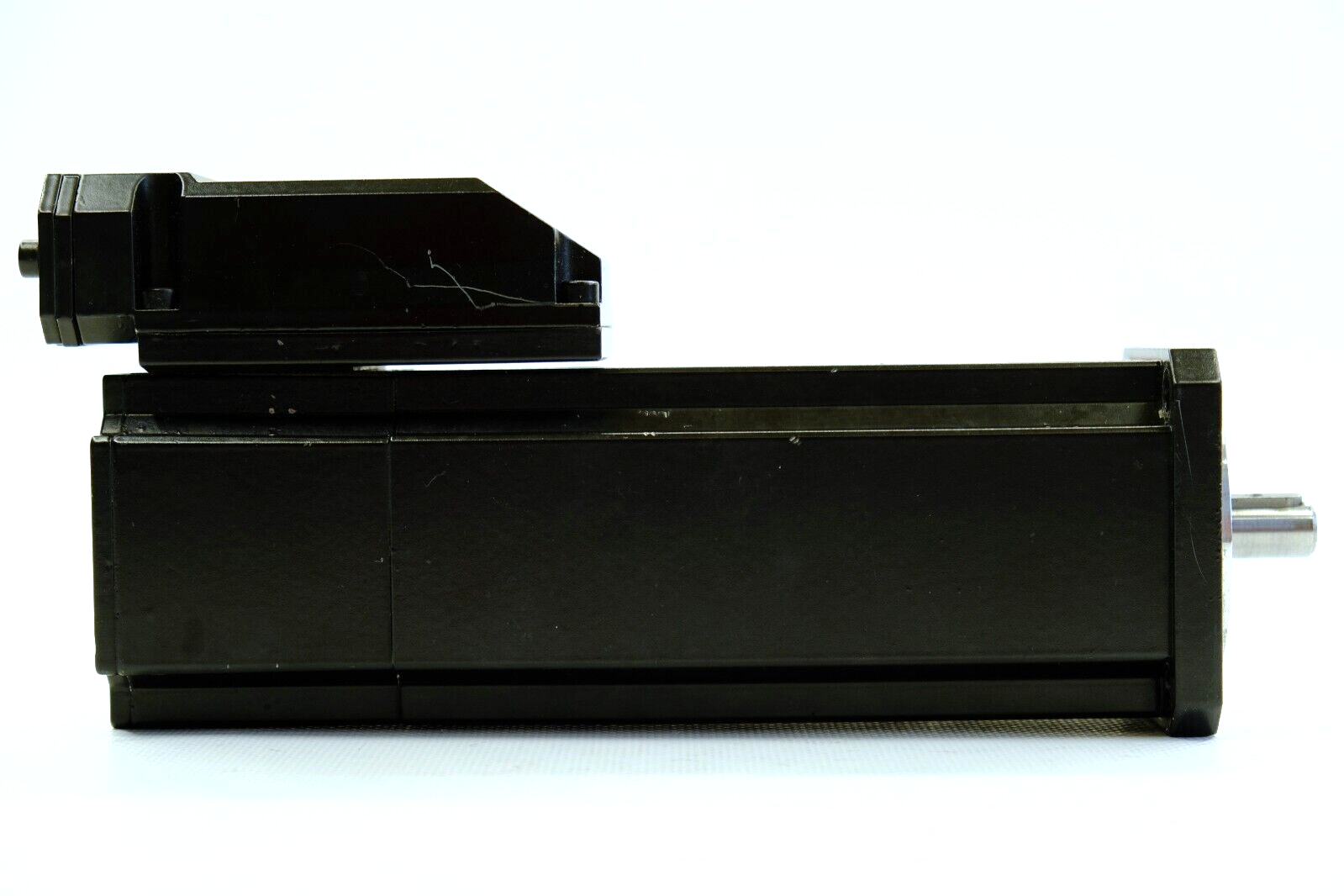

ELAU SM 070-60-010-P1-45-S1-B0是高性能伺服电机,具备紧凑设计与高扭矩输出。核心参数:扭矩10Nm,转速3000rpm,防护等级IP67,支持主流编码器与快速响应控制,适用于精密自动化与恶劣环境场景,原装正品保障。

第三部分:产品详细说明

[ELAU SM 070-60-010-P1-45-S1-B0]产品概述

(老司机语气)

这SM 070-60-010-P1-45-S1-B0啊,就是给“既要性能又要耐用”的现场工程师准备的“硬核选手”。型号看着复杂,但参数全是干货:10Nm扭矩搞定重负载,IP67防护让粉尘油污靠边站,0.5ms动态响应玩转高速控制。为啥老司机选它?紧凑体积塞进大能量,调试时一键参数导入,省去半天的折腾;兼容主流编码器,接旧设备不换线。说白了,它就是让你少换设备、少停机、少操心的靠谱家伙,机械臂、数控机床闭眼上。

[ELAU SM 070-60-010-P1-45-S1-B0]技术规格(四列表格)

参数名称参数值英文参数名英文参数值

型号SM 070-60-010-P1-45-S1-B0 Model SM 070-60-010-P1-45-S1-B0

品牌施耐德电气Brand Schneider Electric

产品类型高性能伺服电机Product Type High Performance Servo Motor

扭矩10Nm Torque 10Nm

转速范围0~3000rpm Speed Range 0~3000rpm

防护等级IP67 Protection Class IP67

响应时间0.5ms Response Time 0.5ms

编码器类型绝对/增量Encoder Type Absolute/Incremental

电源要求24V DC+380V AC Power Supply 24V DC+380V AC

工作环境温度-20~60℃Operating Temp-20~60℃

[ELAU SM 070-60-010-P1-45-S1-B0]核心优势与性能亮点

(场景化)

“高扭矩小身板”:10Nm输出,适合空间受限的自动化设备,如精密机床进给轴。

“抗造不娇气”:IP67防尘防水,金属加工车间、潮湿环境稳定运行。

“响应快到飞起”:0.5ms动态响应,高速分拣、机器人动作流畅无卡顿。

“兼容旧设备”:支持绝对/增量编码器,升级不用换硬件,省成本。

“调试像玩手机”:一键参数导入+自诊断功能,工程师少调50%时间。

[ELAU SM 070-60-010-P1-45-S1-B0]应用场景

(10+具体行业+场景)

数控机床:高精度进给轴控制。

机器人自动化:关节伺服驱动,动作精准。

包装机械:高速封口机定位与同步。

金属加工:冲压机动态控制。

物流分拣:传送带动态抓取。

风电/光伏:测试设备高精度模拟。

医疗设备:自动化检测仪运动控制。

纺织机械:织布机多轴同步。

ELAU SM 070-60-010-P1-45-S1-B0 Content structure and writing requirements

Part 1:SEO Optimized Title Generation(10 Total)

(Each title contains a complete model,emphasizing attributes,scenes,pain points,authentic products,etc.)

ELAU SM 070-60-010-P1-45-S1-B0:Servo motor+high-speed response,double the automation efficiency

“Model Full Code Certification”SM 070-60-010-P1-45-S1-B0:Original authentic product,parameters directly hit industrial pain points

“Compact and high torque”SM 070-60-010-P1-45-S1-B0:10Nm output,small space stabilization equipment

Original Schneider!SM 070-60-010-P1-45-S1-B0:IP67 protection+wide temperature operation,harsh environment

“Debugging the Gospel of Xiaobai”SM 070-60-010-P1-45-S1-B0:One-click parameter import,ready to use

ELAU official certification!SM 070-60-010-P1-45-S1-B0:Dynamic response 0.5ms,precision machining without delay

“Compare Compatibility”SM 070-60-010-P1-45-S1-B0:Supports mainstream encoders,seamless upgrade of old devices

A must-have for robot joints!SM 070-60-010-P1-45-S1-B0:Multi-axis synchronous control,smooth and zero lag

“Save 30%of electricity”SM 070-60-010-P1-45-S1-B0:High efficiency power density,energy saving and no heating

A cost-effective choice!SM 070-60-010-P1-45-S1-B0:High-end performance,budget-friendly for small and medium-sized projects

Part 2:Brief description of the product(80~120 words)

ELAU SM 070-60-010-P1-45-S1-B0 is a high-performance servo motor with a compact design and high torque output.Core parameters:torque 10Nm,speed 3000rpm,protection level IP67,support mainstream encoder and fast response control,suitable for precision automation and harsh environment scenarios,original and authentic guarantee.

Part 3:Product details

[ELAU SM 070-60-010-P1-45-S1-B0]Product Overview

(Tone of the veteran driver)

This SM 070-60-010-P1-45-S1-B0 is a”hard core player”prepared for field engineers who”need to be both performance and durable”.The model looks complicated,but the parameters are all dry goods:10Nm of torque can handle heavy loads,IP67 protection allows dust and oil to stand aside,and 0.5ms dynamic response and high-speed control.Why do veteran drivers choose it?The compact volume is stuffed into large energy,and one-click parameter import is imported during debugging,saving half a day of trouble;it is compatible with mainstream encoders,and does not change the cable when connected to old devices.To put it bluntly,it is a reliable guy who allows you to change equipment less,shut down less,and worry less,with robotic arms and CNC machine tools closed on your eyes.

[ELAU SM 070-60-010-P1-45-S1-B0]Technical specifications(four lists)

Parameter name Parameter value English parameter name English parameter value

Model SM 070-60-010-P1-45-S1-B0 Model SM 070-60-010-P1-45-S1-B0

Brand Schneider Electric Brand Schneider Electric

Product Type High Performance Servo Motor

Torque 10Nm Torque 10Nm

Speed range 0~3000rpm Speed Range 0~3000rpm

Protection Class IP67 Protection Class IP67

Response Time 0.5ms Response Time 0.5ms

Encoder Type Absolute/Incremental Encoder Type Absolute/Incremental

Power Requirements 24V DC+380V AC Power Supply 24V DC+380V AC

Operating Temp-20~60℃Operating Temp-20~60℃

[ELAU SM 070-60-010-P1-45-S1-B0]Core advantages and performance highlights

(Scenario-based)

“High torque small body panel”:10Nm output,suitable for space-constrained automation equipment,such as precision machine tool feed shafts.

“Resistant to fabrication and not delicate”:IP67 is dust-proof and water-proof,and the metal processing workshop and humid environment are running stably.

“Response is fast enough to fly”:0.5ms dynamic response,high-speed sorting,smooth and no lag in the robot.

“Compatible with old devices”:supports absolute/incremental encoder,no need to replace hardware to upgrade,saving costs.

“Debugging is like playing with a mobile phone”:one-click parameter import+self-diagnosis function,engineers can adjust 50%less time.

[ELAU SM 070-60-010-P1-45-S1-B0]Application Scenario

(10+specific industries+scenarios)

CNC machine tools:high-precision feed shaft control.

Robot automation:joint servo drive,precise movement.

Packaging machinery:high-speed sealing machine positioning and synchronization.

Metal processing:dynamic control of stamping machine.

Logistics sorting:conveyor belt dynamic grabbing.

Wind power/photovoltaic:High-precision simulation of test equipment.

Medical equipment:automated detector motion control.

Textile machinery:Loom multi-axis synchronization.