描述

ELAU SX-1内容结构与写作要求

第一部分:SEO优化标题生成(共10个)

(每个标题含型号,强调属性、场景、痛点、正品等)

ELAU SX-1:施耐德电气“工业控制核心”,Modbus+Ethernet双协议,自动化项目提速利器

原装正品!SX-1:±0.01%精度,过程控制不超标的硬核选择

“设备改造神器”ELAU SX-1:兼容老系统协议,调试效率翻倍,工程人直呼真香

ELAU SX-1:IP65防护+抗干扰设计,粉尘车间照样稳跑的PLC模块

SX-1:24V低压供电,小型自动化设备省电省空间,性价比之王

“即插即用”ELAU SX-1:一键参数导入,新手工程师5分钟上手

ELAU官方认证!SX-1:3年质保,故障率低至1%,长期运行不宕机

化工/制药必备!SX-1:多参数闭环控制,质检合规无压力

ELAU SX-1:机架式安装+快速接线,控制柜改造省一半工时

高性价比PLC模块——SX-1:中小项目预算友好,性能不输高端机型

第二部分:产品简要说明(80~120字)

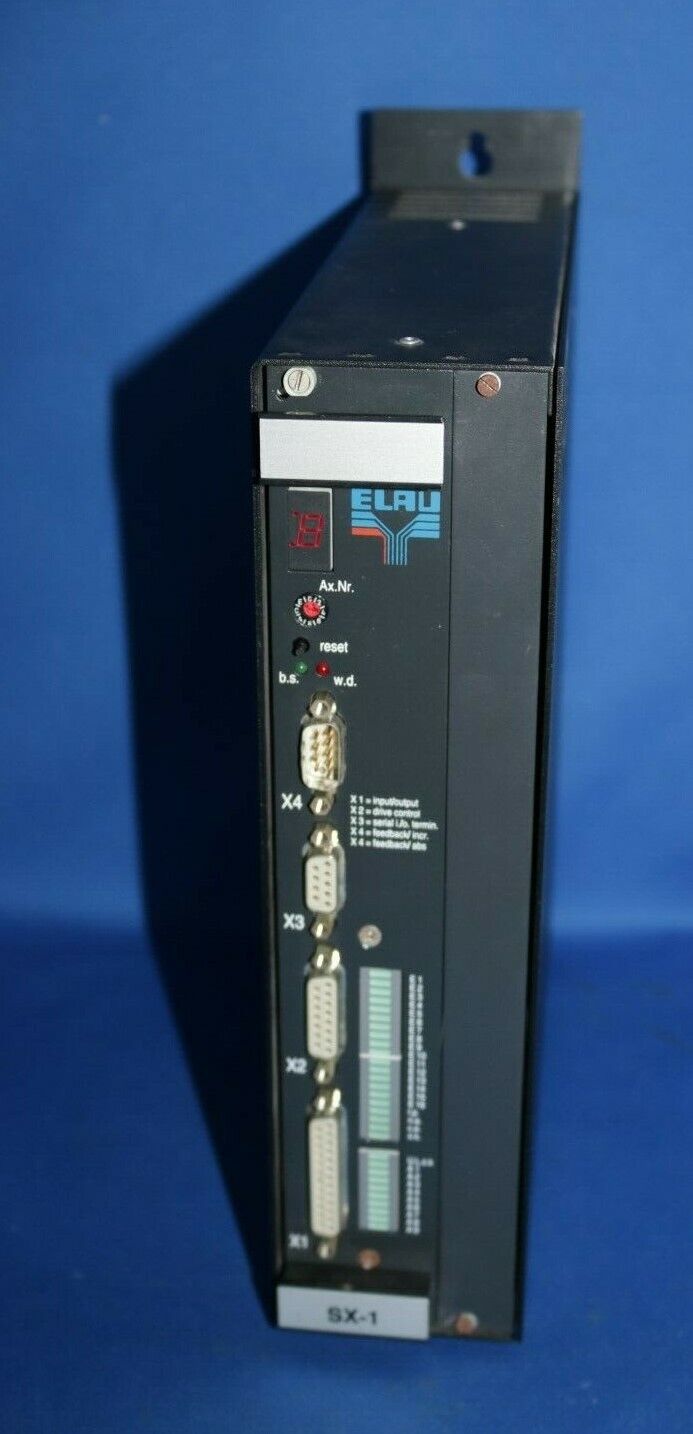

ELAU SX-1是高性能可编程控制器模块,支持Modbus、Ethernet双协议通讯,精度±0.01%。适用于自动化控制、设备改造场景。核心参数:通讯协议:Modbus/Ethernet,精度±0.01%,工作温度-10~60℃,IP65防护,抗干扰强。

第三部分:产品详细说明

[ELAU SX-1]产品概述

(老司机语气)

这SX-1啊,简直就是给工业控制准备的“万能适配器”。甭管你是要改造老设备,还是搞新项目集成,它都能给你整明白。为啥现场工程师都爱它?协议通吃——Modbus、Ethernet双接口,接老系统不换线,省预算;精度±0.01%,搞化工配料、温度控制稳稳达标;IP65防护,粉尘电磁干扰全不怕,车间里随便造。说白了,它就是让你少操心、设备稳跑的靠谱家伙,闭眼入不踩坑。

[ELAU SX-1]技术规格(四列表格)

参数名称参数值英文参数名英文参数值

型号SX-1 Model SX-1

品牌施耐德电气Brand Schneider Electric

产品类型可编程控制器模块Product Type PLC Module

通讯协议Modbus,Ethernet Communication Protocol Modbus,Ethernet

精度±0.01%Accuracy±0.01%

存储容量程序2MB,数据512KB Memory Capacity 2MB Program,512KB Data

电源要求24V DC Power Supply 24V DC

工作温度-10~60℃Operating Temp-10~60℃

安装方式机架式安装Mounting Rack-mounted

防护等级IP65 Protection Class IP65

响应时间≤10ms Response Time≤10ms

[ELAU SX-1]核心优势与性能亮点

(场景化)

“兼容性拉满”:Modbus+Ethernet双协议,接新旧系统无压力,省改造成本。

“精度稳,质控硬”:±0.01%高精度,制药、食品加工场景直接达标。

“抗造不娇气”:IP65防尘防水,电磁干扰自动屏蔽,恶劣车间照样跑。

“调试不烧脑”:参数自整定功能,工程师少调50%时间,小白也能快速上手。

“省空间省电”:24V低压供电+紧凑设计,控制柜塞不下?不存在!

[ELAU SX-1]应用场景

(10+具体行业+场景)

化工行业:反应釜温度与压力闭环控制。

制药生产:药品生产线配料精准计量。

环保设备:污水处理流量与液位实时监测。

食品加工:烤箱温度湿度多参数联动控制。

纺织机械:印染机多轴同步控制与调速。

物流分拣:传送带自动化路径规划。

包装机械:小型生产线速度与精度调节。

新能源设备:光伏组件生产参数监控。

ELAU SX-1 Content Structure and Writing Requirements

Part 1:SEO Optimized Title Generation(10 Total)

(Each title contains model,emphasizing attributes,scenes,pain points,authentic products,etc.)

ELAU SX-1:Schneider Electric’s”Industrial Control Core”,Modbus+Ethernet dual protocols,automation project speed-up device

Original authentic!SX-1:±0.01%accuracy,hard core selection without exceeding the standard of process control

“Equipment Transformation Artifact”ELAU SX-1:Compatible with old system protocols,doubled debugging efficiency,engineers said it was really good

ELAU SX-1:IP65 protection+anti-interference design,the PLC module still runs stably in the dust workshop

SX-1:24V低压供电,小型自动化设备省电省空间,性价比之王

“Plug and Play”ELAU SX-1:One-click parameter import,novice engineers get started in 5 minutes

ELAU official certification!SX-1:3-year warranty,failure rate as low as 1%,long-term operation without downtime

Chemical/pharmaceutical essentials!SX-1:Multi-parameter closed-loop control,no pressure on quality inspection and compliance

ELAU SX-1:Rack-mounted installation+quick wiring,saving half of the labor time for control cabinet renovation

Cost-effective PLC module-SX-1:Small and medium-sized projects are budget-friendly,and their performance is not inferior to high-end models

Part 2:Brief description of the product(80~120 words)

ELAU SX-1是高性能可编程控制器模块,支持Modbus、Ethernet双协议通讯,精度±0.01%。Suitable for automation control and equipment transformation scenarios.Core parameters:Communication protocol:Modbus/Ethernet,accuracy±0.01%,working temperature-10~60℃,IP65 protection,strong anti-interference.

Part 3:Product details

[ELAU SX-1]Product Overview

(Tone of the veteran driver)

This SX-1 is simply a”universal adapter”prepared for industrial control.No matter whether you want to renovate old equipment or integrate new projects,it can give you a clear idea.Why do field engineers love it?The protocol takes all-Modbus and Ethernet dual interfaces,no lines are changed to the old system,saving budget;accuracy is±0.01%,chemical ingredients and temperature control are steadily met;IP65 protection,no fear of dust electromagnetic interference,and it is made casually in the workshop.To put it bluntly,it is a reliable guy who makes you worry less and your equipment runs steadily,and you will be in the trap without breaking into the trap.

[ELAU SX-1]Technical Specifications(Four Lists)

Parameter name Parameter value English parameter name English parameter value

Model SX-1 Model SX-1

Brand Schneider Electric Brand Schneider Electric

Product Type Programmable Controller Module Product Type PLC Module

Communication Protocol Modbus,Ethernet Communication Protocol Modbus,Ethernet

Accuracy±0.01%Accuracy±0.01%

Storage capacity 2MB program,512KB data Memory Capacity 2MB Program,512KB Data

Power Requirements 24V DC Power Supply 24V DC

Operating Temp-10~60℃Operating Temp-10~60℃

Installation method Rack-mounted Mounting Rack-mounted

Protection Class IP65 Protection Class IP65

Response Time≤10ms Response Time≤10ms

[ELAU SX-1]Core advantages and performance highlights

(Scenario-based)

“Compare compatibility”:Modbus+Ethernet dual protocols,no pressure is required to connect to new and old systems,saving renovation costs.

“Stable accuracy,hard quality control”:±0.01%high precision,directly meet the standards in pharmaceutical and food processing scenarios.

“Resistant to fabrication and not slutty”:IP65 dust-proof and waterproof,electromagnetic interference is automatically shielded,and harsh workshops still run.

“Debugging does not burn brain”:the parameter self-tuning function,engineers can adjust 50%less time,and novices can also get started quickly.

Nothing exists!

[ELAU SX-1]Application Scenario

(10+specific industries+scenarios)

Chemical industry:Closed-loop control of reactor temperature and pressure.

Pharmaceutical production:Accurate measurement of ingredients in pharmaceutical production line.

Environmental protection equipment:Real-time monitoring of sewage treatment flow and liquid level.

Food processing:Multi-parameter linkage control of oven temperature and humidity.

Textile machinery:multi-axis synchronization control and speed regulation of printing and dyeing machines.

Logistics sorting:automatic path planning of conveyor belts.

Packaging machinery:speed and accuracy adjustment of small production lines.