描述

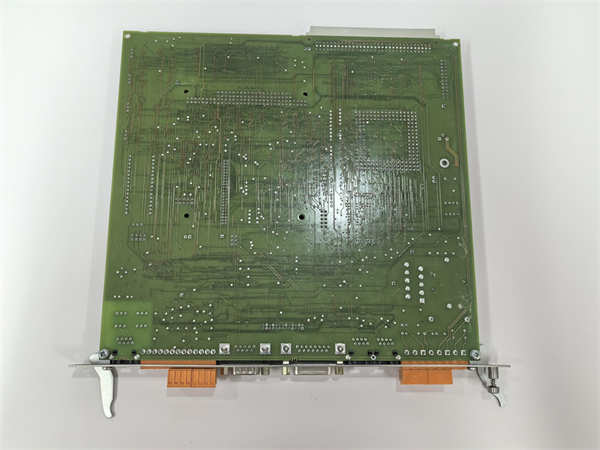

EMERSON A6824R 9199-00098-13技术工控解析:工业通信与冗余监控的高可靠性接口模块

一、产品概述

EMERSON A6824R 9199-00098-13是艾默生(Emerson)推出的ModBus和机架接口模块,专为旋转机械保护系统设计,符合API 670标准。该模块支持Modbus RTU(串行)和Modbus TCP/IP(以太网)双协议通信,可冗余配置,适用于蒸汽、燃气、压缩机及水力涡轮机械的机械健康监测与保护。其核心功能包括数据采集、传输及系统集成,是艾默生AMS 6500监控系统的关键组件。

二、核心功能与技术特性

1.通信协议与冗余设计

双协议支持:

Modbus RTU:通过RS-485串口传输数据,速率19.2 kbps,配置奇偶校验与停止位。

Modbus TCP/IP:通过RJ45接口实现以太网通信,支持10BaseT协议。

冗余路径:可同时配置两种协议作为冗余链路,提升系统可靠性。

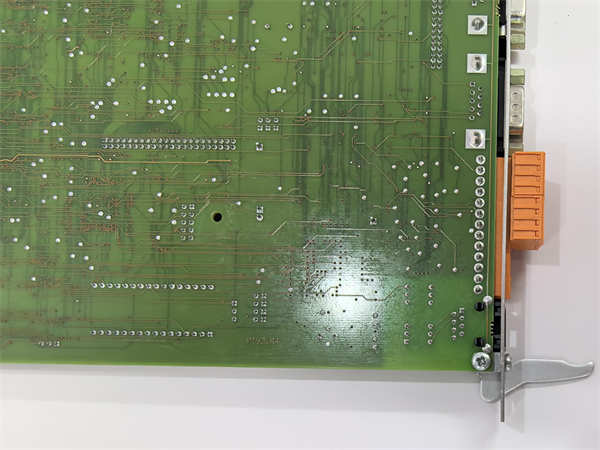

2.硬件规格与兼容性

物理参数:

尺寸:4TE宽度(19.98mm),3U高度,支持19英寸机架安装(兼容IMR6500系列)。

电源:24V DC输入,最大功耗5W。

环境适应性:

工作温度:0°C–65°C,存储温度-30°C–85°C。

防护等级:IP 00(模块)与IP 21(前板),符合工业级振动与冲击标准(IEC 68-2)。

3.数据管理与集成

数据类型:

支持采集速度、振动(1/2x/1x)、间隙值、报警状态、相位等机械参数。

系统集成:

与DeltaV DCS、Ovation等控制系统无缝对接,提供实时数据监控与报警功能。

可连接A6000显示器(最多8台),实现集中化管理。

三、典型应用场景

旋转机械保护

监测汽轮机、压缩机的振动、转速等参数,触发保护动作(如紧急停机)。

工业过程控制

作为API 670机械保护系统的核心模块,与AMS 6500监控器配合,确保设备安全运行。

智能工厂集成

通过Modbus协议与上位机系统(如SCADA)通信,支持数据可视化与远程诊断。

P152.R4

P152.R4

EMERSON A6824R 9199-00098-13 Technical Industrial Control Analysis:High Reliability Interface Module for Industrial Communication and Redundant Monitoring

1.Product Overview

EMERSON A6824R 9199-00098-13 is a ModBus and rack interface module from Emerson,designed for rotary mechanical protection systems and comply with API 670 standards.This module supports dual protocol communication between Modbus RTU(serial)and Modbus TCP/IP(Ethernet)and can be redundantly configured,suitable for mechanical health monitoring and protection of steam,gas,compressors and hydraulic turbine machinery.Its core functions include data acquisition,transmission and system integration,and are a key component of Emerson’s AMS 6500 monitoring system.

2.Core functions and technical characteristics

1.Communication protocol and redundancy design

Dual protocol support:

Modbus RTU:Transfer data through the RS-485 serial port,with a rate of 19.2 kbps,and configure parity and stop bits.

Modbus TCP/IP:Enables Ethernet communication through the RJ45 interface and supports 10BaseT protocol.

Redundant path:Two protocols can be configured as redundant links at the same time to improve system reliability.

2.Hardware specifications and compatibility

Physical parameters:

Dimensions:4TE width(19.98mm),3U height,support for 19-inch rack mount(compatible with IMR6500 series).

Power supply:24V DC input,maximum power consumption 5W.

Environmental adaptability:

Operating temperature:0°C–65°C,storage temperature-30°C–85°C.

Protection level:IP 00(module)and IP 21(front plate),complies with industrial-grade vibration and impact standards(IEC 68-2).

3.Data management and integration

Data type:

Supports the acquisition of mechanical parameters such as speed,vibration(1/2x/1x),gap value,alarm status,phase,etc.

System integration:

Seamlessly connect with control systems such as DeltaV DCS,Ovation,etc.,providing real-time data monitoring and alarm functions.

A6000 monitors can be connected(up to 8 units)for centralized management.

3.Typical application scenarios

Rotary mechanical protection

Monitor the vibration,speed and other parameters of the turbine and compressor,and trigger protection actions(such as emergency shutdown).

Industrial process control

As the core module of the API 670 mechanical protection system,it cooperates with the AMS 6500 monitor to ensure the safe operation of the equipment.

Smart factory integration

Communication with host computer systems(such as SCADA)through the Modbus protocol,supporting data visualization and remote diagnosis.