描述

主要特性和规格

功能:数字轴向位置保护系统(DAPS)。

通道:基于微控制器的三通道测量系统。该系统可实现轴位置的冗余和高可靠性监控,通常采用三选二(2oo3)表决逻辑来控制报警输出,从而增强安全性。

传感器兼容性:主要设计用于EPRO/Emerson的电感式位移传感器(例如涡流探头)。这些传感器可对轴位置进行连续、非接触式测量。

输出信号:

电流输出:通常每个通道提供两个电流输出(例如0/4-20mA),其中至少一个为电气隔离输出。这些输出可馈入分布式控制系统(DCS)、可编程逻辑控制器(PLC)或专用振动分析系统。

报警输出:具有多个限值输出(每通道最多6个),通常为无源继电器触点或防短路二进制24V输出。当超过预设的位移阈值时,这些输出会激活,发出潜在问题的信号。

安全特性:

高安全级别:通过密码保护增强配置。

自检功能:持续自检电子电路和传感器,确保系统完整性。故障通过输出触点和显示屏(如有配备)上的纯文本消息指示。

模拟量比较:在三个通道之间进行模拟量比较,以检测传感器或测量链的差异。

冗余电源:支持为监测器和背板提供冗余直流电源输入,从而提高可靠性。

通信接口:

RS232接口:位于前端,用于使用PC进行本地参数输入和配置。

RS485接口:用于与主机或其他模块进行数据交换。

PROFIBUS-DP接口(可选):可无缝集成到更大型的工业自动化网络中。

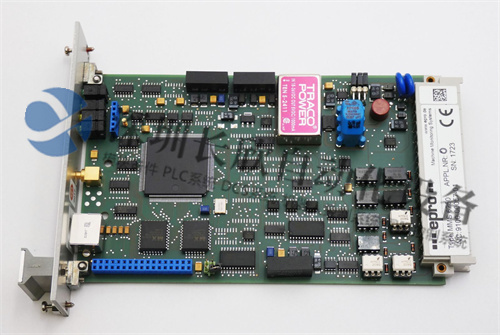

物理特性:

外形尺寸:通常为模块卡,可安装于机架系统(例如19英寸机架)。

尺寸:约3.1厘米(宽)x 19.1厘米(深)x 12.8厘米(高)或类似尺寸,具体取决于具体型号。

重量:约0.56千克(或0.7千克/0.8千克,具体取决于具体型号和包装)。

性能:

精度:通常约为满量程的±0.1%。

分辨率:高分辨率,可能精确到0.001毫米,可精确监测微小位移。

采样率:连续数据记录,采样率约为100 Hz。

应用:

对于涡轮机监测系统至关重要,可取代老式的机械位置控制和保护系统。

适用于数控机械、冶金、石油天然气和石化行业,防止因轴过度运动而导致的设备损坏。

这对于预测性维护策略至关重要,使操作员能够实时监控设备健康状况并主动干预。

Key Features and Specifications

Function:Digital Axial Position Protection System(DAPS).

Channels:Microcontroller-based 3-channel measuring system.This allows for redundant and highly reliable monitoring of shaft position,often with a 2-out-of-3(2oo3)voting logic for alarm outputs to enhance safety.

Sensor Compatibility:Primarily designed for use with inductive displacement sensors(e.g.,eddy current probes)from EPRO/Emerson.These sensors provide continuous,non-contact measurement of shaft position.

Output Signals:

Current Outputs:Typically provides two current outputs(e.g.,0/4-20mA)per channel,with at least one being electrically isolated.These outputs can be fed into Distributed Control Systems(DCS),Programmable Logic Controllers(PLC),or dedicated vibration analysis systems.

Alarm Outputs:Features multiple limit value outputs(up to 6 per channel)which are often potential-free relay contacts or short-circuit proof binary 24V outputs.These activate when pre-set displacement thresholds are exceeded,signaling a potential issue.

Safety Features:

High Safety Level:Enhanced by password protection for configuration.

Self-Test Functions:Continuous self-monitoring of electronic circuits and sensors to ensure the system’s integrity.Faults are indicated via output contacts and plain text messages on a display(if equipped).

Analog Comparison:Performs analog comparison between the three channels to detect sensor or measurement chain discrepancies.

Redundant Supplies:Supports redundant DC power inputs for both the monitors and the backplane,increasing reliability.

Communication Interfaces:

RS232 Interface:Located on the front for local parameter input and configuration using a PC.

RS485 Interface:For data exchange with a host computer or other modules.

PROFIBUS-DP Interface(Optional):Allows for seamless integration into larger industrial automation networks.

Physical Characteristics:

Form Factor:Typically a module card designed to fit into a rack system(e.g.,19-inch racks).

Dimensions:Approximately 3.1 cm(width)x 19.1 cm(depth)x 12.8 cm(height)or similar,depending on the specific variant.

Weight:Around 0.56 kg(or 0.7 kg/0.8 kg depending on the exact model and packaging).

Performance:

Accuracy:Often specified around±0.1%of full scale.

Resolution:High resolution,potentially down to 0.001 mm,for precise monitoring of small displacements.

Sampling Rate:Continuous data logging,with sampling rates around 100 Hz.

Application:

Critical for turbine monitoring systems,replacing older mechanical position control and protection systems.

Used in CNC machinery,metallurgy,oil and gas,and petrochemicals to prevent equipment damage due to excessive shaft movement.

Crucial for predictive maintenance strategies,allowing operators to monitor equipment health in real-time and intervene proactively.

ABB 型号:GBU72 3BHE055094R0002 型号:3BHE055094R0002 GBU72 型号:GBU72 型号:3BHE055094R0002 型号:3BHE031197R0001 型号:3BHB030310R0001 型号:73BHE055094R0002 GBU72 型号:73BHE055094R0002 型号:GBU72 型号:ABB PCS6000 PRODUCT FAMLIYABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101