描述

EPRO MMS6418是一款双通道测量放大器,专为精确监测关键旋转机械中的相对和绝对轴膨胀而设计。作为EPRO(现为艾默生)MMS 6000机器监控系统的一部分,它在预测性维护和机器保护中发挥着至关重要的作用。

主要特点和规格

双通道操作:MMS6418提供两个独立的测量通道,每个通道均针对特定类型的位移测量进行定制:

通道1(绝对膨胀):设计用于与半桥电路或差动变压器配置中的电感式位移传感器(例如EPRO PR 9350系列)配合使用。此通道通常测量相对于固定点的绝对轴位移。

通道2(相对膨胀):主要用于与PR 6418系列等传感器配合使用。此通道测量相对膨胀,通常是两个部件之间的长度差或轴在其壳体内的相对运动。

测量范围:

通道1:灵活的测量范围取决于所连接的传感器类型,测量频率范围为0-100 Hz(-3dB)。

通道2:通常提供±10 mm或±20 mm等测量范围,测量频率范围为0-10 Hz(-3dB)。

信号处理:

计算能力:该模块可以处理来自两个通道的信号,计算总和值或差值,这对于确定整体轴振动或偏心率特别有用。

精度:高精度,通常约为测量范围的±1%。

分辨率:提供高分辨率(例如,电压输出为9位)。

输出:

模拟电压输出:每通道一个电压输出(例如,0…+10 V),与传感器信号成比例,可用于连接示波器或其他诊断设备。

电流输出:可提供隔离电流输出(例如0/4-20mA),以便与DCS(分布式控制系统)、PLC(可编程逻辑控制器)或专用振动分析系统集成。

传感器激励:该模块为每个通道提供独立的缓冲传感器电源输出,并采用特定的载波频率(例如,通道1为4.75 kHz,通道2为1963 Hz)。这些输出具有对地平衡、开路和短路保护功能,确保传感器可靠运行。

通信接口:

RS232:前面板RS232接口允许使用PC进行本地配置和数据读取。

RS485:用于与主机或EPRO MMS 6800诊断系统进行数据交换。

诊断功能:

状态LED:前面板上配备LED,用于指示“通道清除”状态和警报情况。

自检功能:包括内部自检功能,用于监控模块和所连接传感器的健康状况,从而提高系统可靠性。

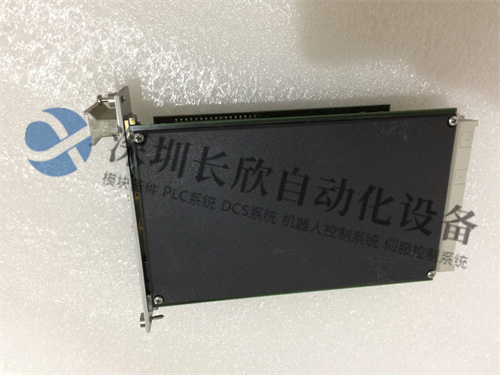

物理特性:

外形尺寸:通常为插卡式,设计用于安装在EPRO MMS 6000机架系统(例如19英寸机架)中。

尺寸和重量:紧凑型设计,典型重量约为0.3公斤。

电源:采用标称24 VDC电源,通常由机架背板提供。

应用:

涡轮机监测:是监测蒸汽、燃气和水力涡轮机轴膨胀的必备工具,这对于防止转子-定子摩擦以及确保启动、停机和负载变化期间的安全运行至关重要。

压缩机和大型电机:用于监测轴向轴的位置和相对运动,有助于检测轴承磨损或推力不平衡。

其他旋转机械:适用于任何需要精确测量位移或膨胀以进行状态监测和保护的机械。

The EPRO MMS6418 is a dual-channel measuring amplifier designed for precise monitoring of relative and absolute shaft expansion in critical rotating machinery.As part of the EPRO(now Emerson)MMS 6000 machine monitoring system,it plays a vital role in predictive maintenance and machine protection.

Key Features and Specifications

Dual-Channel Operation:The MMS6418 offers two independent measuring channels,each tailored for specific types of displacement measurements:

Channel 1(Absolute Expansion):Designed to work with inductive displacement transducers(e.g.,EPRO PR 9350 series)in a half-bridge circuit or differential transformer configuration.This channel typically measures absolute shaft movement relative to a fixed point.

Channel 2(Relative Expansion):Primarily for use with sensors like the PR 6418 series.This channel measures relative expansion,often the difference in length between two components or the relative movement of a shaft within its casing.

Measurement Ranges:

Channel 1:Flexible measuring ranges depending on the connected sensor type,with a measuring frequency range of 0-100 Hz(-3dB).

Channel 2:Typically offers measuring ranges such as±10 mm or±20 mm,with a measuring frequency range of 0-10 Hz(-3dB).

Signal Processing:

Calculation Capabilities:The module can process signals from both channels to calculate sum or difference values,which is particularly useful for determining overall shaft vibration or eccentricity.

Accuracy:High accuracy,typically specified around±1%of the measuring range.

Resolution:Provides high resolution(e.g.,9-bit for voltage outputs).

Outputs:

Analog Voltage Outputs:One voltage output per channel(e.g.,0…+10 V),proportional to the sensor signal,useful for connecting to oscilloscopes or other diagnostic equipment.

Current Outputs:Can provide isolated current outputs(e.g.,0/4-20mA)for integration with DCS(Distributed Control Systems),PLCs(Programmable Logic Controllers),or dedicated vibration analysis systems.

Sensor Excitation:The module provides separate,buffered sensor supply outputs for each channel with specific carrier frequencies(e.g.,4.75 kHz for Channel 1 and 1963 Hz for Channel 2).These outputs are balanced to ground,open-circuit,and short-circuit proof,ensuring reliable sensor operation.

Communication Interfaces:

RS232:A front-panel RS232 interface allows for local configuration and data readout using a PC.

RS485:For data exchange with a host computer or the EPRO MMS 6800 diagnosis system.

Diagnostic Features:

Status LEDs:Equipped with LEDs on the front panel to indicate”Channel Clear”status and alarm conditions.

Self-Check Functions:Includes internal self-checking to monitor the health of the module and connected sensors,enhancing system reliability.

Physical Characteristics:

Form Factor:Typically a plug-in card designed for installation in the EPRO MMS 6000 rack system(e.g.,a 19-inch rack).

Dimensions and Weight:Compact design,with a typical weight around 0.3 kg.

Power Supply:Operates on a nominal 24 VDC power supply,typically provided by the rack’s backplane.

Applications:

Turbine Monitoring:Essential for monitoring shaft expansion in steam,gas,and hydro turbines,which is critical for preventing rotor-stator rubs and ensuring safe operation during startup,shutdown,and load changes.

Compressors and Large Motors:Used to monitor axial shaft position and relative movements,helping to detect bearing wear or thrust imbalances.

Other Rotating Machinery:Applicable to any machinery where precise displacement or expansion measurement is critical for condition monitoring and protection.

ABB型号:GBU72 3BHE055094R0002型号:3BHE055094R0002 GBU72型号:GBU72型号:3BHE055094R0002型号:3BHE031197R0001型号:3BHB030310R0001型号:73BHE055094R0002 GBU72型号:73BHE055094R0002型号:GBU72型号:ABB PCS6000 PRODUCT FAMLIYABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB 型号:GBU72 3BHE055094R0002 型号:3BHE055094R0002 GBU72 型号:GBU72 型号:3BHE055094R0002 型号:3BHE031197R0001 型号:3BHB030310R0001 型号:73BHE055094R0002 GBU72 型号:73BHE055094R0002 型号:GBU72 型号:ABB PCS6000 PRODUCT FAMLIYABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101