描述

EPRO MMS6620产品详情解析

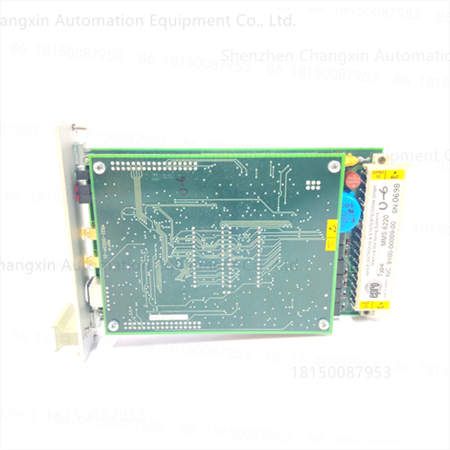

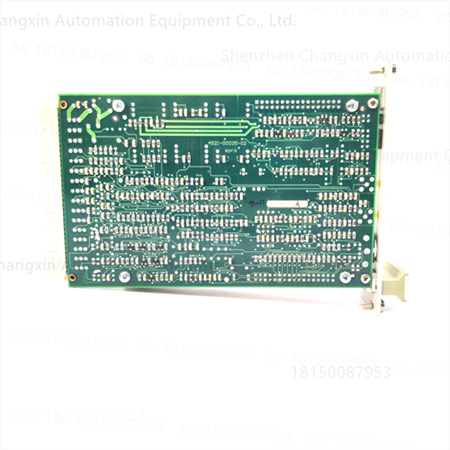

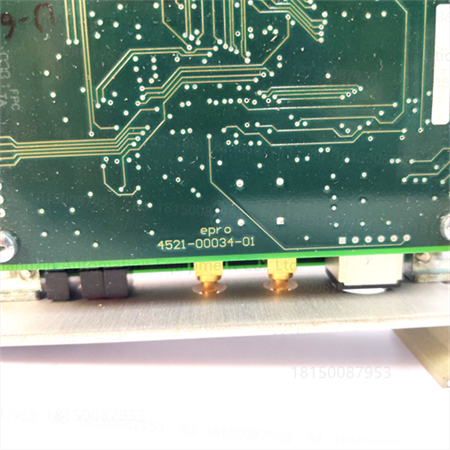

EPRO MMS6620是PRÜFTECHNIK(普卢福)集团旗下EPRO品牌推出的一款高端多通道振动与动态压力监测模块,专为高速旋转机械(如燃气轮机、航空发动机、蒸汽轮机、高速压缩机)的复杂状态监测需求设计。该模块集成了高采样率振动信号采集、动态压力测量、温度补偿、实时频谱分析等功能,支持同步多参数监测、高速数据传输、高级故障诊断,广泛应用于电力、航空航天、石油化工、冶金等行业的高端设备预测性维护。以下从产品定位、核心功能、技术规格、应用场景及选型建议五方面详细解析:

一、产品定位与核心功能

所属系统

PRÜFTECHNIK Condition Monitoring Platform:作为EPRO系列监测系统的旗舰模块,MMS6620可独立运行或集成至VIBGUARD 7000、VIBROWAVE Pro等高级监测平台,实现设备状态实时可视化、故障预警与深度数据分析。

模块类型:

高速振动+动态压力监测模块:支持同时采集振动(加速度/速度/位移)、动态压力、温度等参数,满足高速机械(如转子动力学分析、气动激励监测)的复杂监测需求。

核心优势

超高速信号采集:单通道最高512kHz采样率,支持超声频段(20kHz~100kHz)振动监测,捕捉高速机械的微小故障特征(如齿轮微点蚀、轴承早期剥落)。

动态压力同步监测:集成高频压力传感器接口燃烧室压力波动、气动噪声、转子叶片通过频率等动态压力信号分析。

多参数同步触发:支持振动+压力+温度同步触发采集,确保故障信号的时间相关性(如燃烧振荡与振动耦合分析)。

高级信号处理:内置阶次跟踪、包络解调、时频分析(STFT)等算法,支持变速机械(如变频驱动泵)和非平稳信号的故障诊断。

高可靠性设计:采用冗余电源、热插拔模块、工业级元器件,适应-40℃~+85℃极端环境,满足ATEX/IECEx防爆认证(可选)。

二、技术规格与参数

1.振动信号采集

参数规格

通道数4/8通道(可选,型号如MMS6620-4、MMS6620-8)

传感器类型加速度(IEPE)、速度(磁电式)、位移(电涡流/激光位移)

输入范围加速度:±100g(高频优化);速度:0~500mm/s(峰值);位移:0~2mm(峰峰值)

采样频率单通道最高512kHz(可分频设置,如256kHz、128kHz)

分辨率24位ADC,动态范围>110dB

抗混叠滤波硬件滤波(截止频率可配置至200kHz)+软件数字滤波(如FIR/IIR滤波器)

EPRO MMS6620 Product Details

The EPRO MMS6620,launched by EPRO,a brand within the PRÜFTECHNIK Group,is a high-end multi-channel vibration and dynamic pressure monitoring module designed specifically for the complex condition monitoring needs of high-speed rotating machinery(such as gas turbines,aircraft engines,steam turbines,and high-speed compressors).The module integrates high-sampling-rate vibration signal acquisition,dynamic pressure measurement,temperature compensation,and real-time spectrum analysis.It supports simultaneous multi-parameter monitoring,high-speed data transmission,and advanced fault diagnosis.It is widely used for predictive maintenance of high-end equipment in industries such as power generation,aerospace,petrochemicals,and metallurgy.The following is a detailed analysis of the product’s positioning,core functions,technical specifications,application scenarios,and selection recommendations:

1.Product Positioning and Core Functions

System

PRÜFTECHNIK Condition Monitoring Platform:As the flagship module of the EPRO series of monitoring systems,the MMS6620 can operate independently or be integrated into advanced monitoring platforms such as VIBGUARD 7000 and VIBROWAVE Pro,enabling real-time visualization of equipment status,fault warnings,and in-depth data analysis.Module Type:

High-SpeedVibration+Dynamic Pressure Monitoring Module:Supports simultaneous acquisition of vibration(acceleration/velocity/displacement),dynamic pressure,temperature,and other parameters,meeting the complex monitoring needs of high-speed machinery(such as rotor dynamics analysis and aerodynamic excitation monitoring).

Core Advantages

Ultra-High-SpeedSignal Acquisition:Single-channel sampling rate up to 512kHz,supporting ultrasonic frequency band(20kHz-100kHz)vibration monitoring,capturing subtle fault characteristics of high-speed machinery(such as gear micropitting and premature bearing spalling).

Synchronous Dynamic Pressure Monitoring:Integrated high-frequency pressure sensor interface analyzes dynamic pressure signals such as combustion chamber pressure fluctuations,aerodynamic noise,and rotor blade pass frequency.

Multi-Parameter Synchronous Triggering:Supports simultaneous triggering of vibration,pressure,and temperature acquisition,ensuring temporal correlation of fault signals(such as analysis of combustion oscillation and vibration coupling).

Advanced Signal Processing:Built-in algorithms such as order tracking,envelope demodulation,and time-frequency analysis(STFT)support fault diagnosis of variable-speed machinery(such as variable-frequency drive pumps)and non-stationary signals.High-reliability design:Utilizing redundant power supplies,hot-swappable modules,and industrial-grade components,it withstands extreme operating temperatures of-40°C to+85°C and meets ATEX/IECEx explosion-proof certification(optional).

II.Technical Specifications and Parameters

1.Vibration Signal Acquisition

Parameters

Number of Channels:4/8 channels(optional,models such as MMS6620-4 and MMS6620-8)

Sensor Type:Acceleration(IEPE),Velocity(Magnetoelectric),Displacement(Eddy Current/Laser Displacement)

Input Range:Acceleration:±100g(high-frequency optimized);Velocity:0-500mm/s(peak);Displacement:0-2mm(peak-to-peak)

Sampling Frequency:Up to 512kHz per channel(dividable,e.g.,256kHz,128kHz)

Resolution:24-bit ADC,dynamic range>110dB

Anti-aliasing Filtering:Hardware filtering(configurable cutoff frequency up to 200kHz)+software digital filtering(e.g.,FIR/IIR filter)

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101