描述

产品概述

EPRO PR6423/003-030是一款电涡流式轴振动传感器,属于EPRO(原飞利浦)MMS系列工业监测系统的核心组件。该传感器采用非接触式测量技术,专为旋转机械的动态位移、振动、轴偏心等参数监测设计,广泛应用于发电厂、石油、化工、压缩机、汽轮机等高精度工业场景。

技术参数

测量范围

量程:±1.0 mm(线性范围2.0 mm)

灵敏度:8 mV/μm(典型值)

频率响应:0.5 Hz至10 kHz(动态测量)

物理特性

探头直径:8 mm

螺纹规格:M10×1或3/8-24UNF(英制)

安装长度:55 mm(标准型号)

电缆类型:铠装或非铠装,长度可选1-8米,末端可选自锁式防水接头或裸线

环境适应性

工作温度:-35°C至+380°C(高温型号需选配)

防护等级:IP67(标准型号)或IP20(部分配置)

防爆等级:Eex ib IIC T6/T4(需加装安全栅)

电气性能

供电电压:-24 V DC

输出信号:

模拟电压:-4 V至-20 V DC(线性输出)

可选4-20 mA电流输出(需配置前置器)

抗干扰能力:符合IEC 60034-14标准,信噪比≥78 dB

核心功能特点

非接触式测量

基于电涡流效应,通过高频线圈与金属轴表面的电磁耦合实现动态位移监测,避免机械磨损。

高精度与稳定性

线性误差≤1.0%(满量程),温漂零点误差≤0.05%/K,时漂误差≤0.01%/24小时。

支持温度补偿(-30°C至+120°C),消除环境温度对测量的影响。

多场景适配

测量类型:轴振动、轴位移、油膜厚度、轴瓦磨损、轴偏心等。

兼容系统:可与EPRO MMS 3000/6000系列监测系统、DCS或PLC接口,支持Modbus、4-20 mA等协议。

抗干扰设计

采用双层屏蔽电缆与差分信号传输技术,抑制电磁干扰(如变频器谐波、电焊机瞬态干扰)。

安装灵活性

支持螺纹安装或法兰安装,螺纹长度可选(25 mm至115 mm),适应不同空间需求。

典型应用场景

电力行业

汽轮机、发电机轴承振动监测(报警阈值≤50μm p-p)。

工业旋转设备

压缩机、泵、风机的轴位移与振动保护。

特殊环境

高温(如燃气轮机高压缸)或防爆区域(如化工厂)。

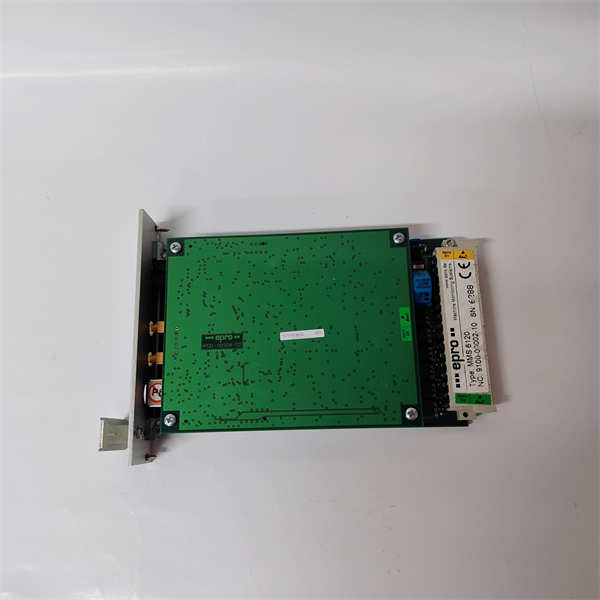

MMS6120 9100-00002-10

MMS6120 9100-00002-10

Product Overview

EPRO PR6423/003-030 is an eddy current shaft vibration sensor,which is the core component of the EPRO(formerly Philips)MMS series industrial monitoring system.The sensor adopts non-contact measurement technology and is designed for the monitoring parameters of rotating machinery such as dynamic displacement,vibration,shaft eccentricity,etc.,and is widely used in high-precision industrial scenarios such as power plants,petroleum,chemicals,compressors,and steam turbines.

Technical parameters

Measurement range

Range:±1.0 mm(linear range 2.0 mm)

Sensitivity:8 mV/μm(typical)

Frequency response:0.5 Hz to 10 kHz(dynamic measurement)

Physical characteristics

Probe diameter:8 mm

Thread specification:M10×1 or 3/8-24UNF(Imperial)

Installation length:55 mm(standard model)

Cable type:Armored or non-armored,length 1-8 meters,ends can be selected from locked waterproof joints or bare wires

Environmental adaptability

Operating temperature:-35°C to+380°C(high temperature model requires optional)

Protection level:IP67(standard model)or IP20(partial configuration)

Explosion-proof grade:Eex ib IIC T6/T4(requires safety barrier)

Electrical performance

Supply voltage:-24 V DC

Output signal:

Analog voltage:-4 V to-20 V DC(linear output)

Optional 4-20 mA current output(protect required)

Anti-interference ability:complies with IEC 60034-14 standard,signal-to-noise ratio≥78 dB

Core functional features

Contactless measurement

Based on the eddy current effect,dynamic displacement monitoring is achieved through electromagnetic coupling between the high-frequency coil and the metal shaft surface to avoid mechanical wear.

High precision and stability

Linear error≤1.0%(full scale),temperature drift zero point error≤0.05%/K,time drift error≤0.01%/24 hours.

Supports temperature compensation(-30°C to+120°C)to eliminate the impact of ambient temperature on measurements.

Multi-scene adaptation

Measurement types:shaft vibration,shaft displacement,oil film thickness,bearing shell wear,shaft eccentricity,etc.

Compatible system:It can interface with EPRO MMS 3000/6000 series monitoring system,DCS or PLC,and supports Modbus,4-20 mA and other protocols.

Anti-interference design

Double-layer shielded cable and differential signal transmission technology are used to suppress electromagnetic interference(such as inverter harmonics and transient interference of welding machines).

Installation flexibility

Supports threaded or flange installation,with optional thread length(25 mm to 115 mm)to meet different space needs.

Typical application scenarios

Electricity Industry

Steam turbine and generator bearing vibration monitoring(alarm threshold≤50μm p-p).

Industrial rotary equipment

Axial displacement and vibration protection of compressors,pumps,and fans.

Special environment

High temperature(such as high pressure cylinder of gas turbine)or explosion-proof areas(such as chemical plants).