描述

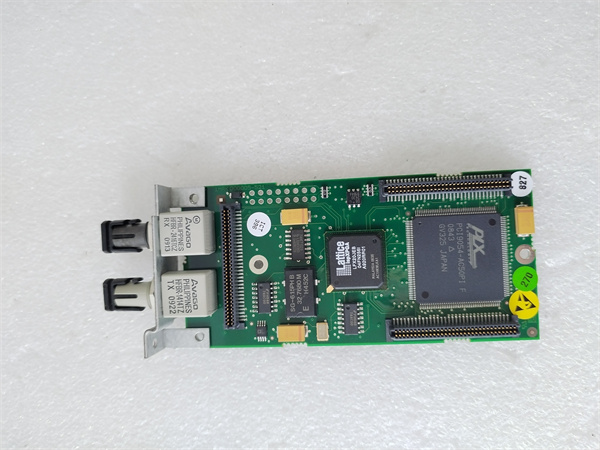

EPRO IMR6000/10是一款高性能的PLC模块卡件,专为工业自动化系统设计,具备广泛的控制功能与高可靠性。以下是其核心特性与技术参数的综合概述:

一、技术参数

电气规格

-电压:24V DC

-输入电流:100-400A

-重量:2kg

-包装:完整封装

-产地:瑞士

环境适应性

-工作温度:0-60℃(符合DIN 40040标准)

-存储温度:-40-85℃

-振动耐受:符合IEC 68-2-29标准,98 m/s²(9.98G)峰值加速度

-电磁兼容性(EMC):通过EN 50081/EN 50082-1/2认证

二、核心功能

多协议通信

-支持RS485接口,传输速率9.6-115.2 kbps

-兼容Modbus等工业协议,可与上位机无缝通信

模块化扩展

-作为背板框架,支持多种I/O模块扩展,如16通道继电器输出、模拟量输入等

-允许布尔逻辑、时滞配置,灵活定制控制策略

数据采集与监控

-集成A/D转换单元,支持模拟量到数字量的实时转换

-支持PID或模糊控制算法,适用于高精度控制场景

运动控制能力

-兼容NC(数字控制)原理,支持多轴运动控制与曲线插补

-脉冲输入/输出频率可达几十kHz,满足伺服系统需求

三、应用场景

工业控制

-用于金属加工、化工、电力等领域,实现开关量与模拟量混合控制

-支持数据采集与远程监控,优化设备运维效率

机械保护

-配合传感器模块,监测旋转机械(如压缩机、涡轮)的振动、温度等参数

-提供报警输出与逻辑控制,预防设备故障

智能电网

-实时记录用电数据,支持分时计价与负荷管理

四、设计优势

高可靠性:冗余供电设计(18-31.2V DC),符合IEC 654-2标准

灵活性:支持定制化逻辑编程,适应复杂控制需求

维护便捷:模块化结构便于更换与扩展

EPRO IMR6000/10 is a high-performance PLC module card designed for industrial automation systems with a wide range of control functions and high reliability.The following is a comprehensive overview of its core features and technical parameters:

I.Technical parameters

Electrical specifications

-Voltage:24V DC

-Input current:100-400A

-Weight:2kg

-Packaging:Complete package

-Origin:Switzerland

Environmental adaptability

-Operating temperature:0-60℃(compliant with DIN 40040 standard)

-Storage temperature:-40-85℃

-Vibration tolerance:compliant with IEC 68-2-29 standard,98 m/s²(9.98G)peak acceleration

-Electromagnetic compatibility(EMC):certified by EN 50081/EN 50082-1/2

II.Core functions

Multi-protocol communication

-Support RS485 interface,transmission rate 9.6-115.2 kbps

-Compatible with industrial protocols such as Modbus,and can communicate seamlessly with the host computer

Modular expansion

-As a backplane framework,it supports a variety of I/O module expansions,such as 16-channel relay output,analog input,etc.

-Allows Boolean logic and time delay configuration,and flexible customization of control strategies

Data acquisition and monitoring

-Integrated A/D conversion unit,supports real-time conversion from analog to digital

-Supports PID or fuzzy control algorithms,suitable for high-precision control scenarios

Motion control capabilities

-Compatible with NC(digital control)principles,supports multi-axis motion control and curve interpolation

-Pulse input/output frequency can reach tens of kHz,meeting the needs of servo systems

III.Application scenarios

Industrial control

-Used in metal processing,chemical industry,electric power and other fields to achieve mixed control of switch quantity and analog quantity

-Support data acquisition and remote monitoring to optimize equipment operation and maintenance efficiency

Mechanical protection

-Cooperate with sensor modules to monitor vibration,temperature and other parameters of rotating machinery(such as compressors and turbines)

-Provide alarm output and logic control to prevent equipment failure

Smart grid

-Real-time recording of electricity consumption data,supporting time-of-use pricing and load management

IV.Design advantages

High reliability:redundant power supply design(18-31.2V DC),in compliance with IEC 654-2 standard

Flexibility:supports customized logic programming,adapting to complex control requirements

Easy maintenance:modular structure facilitates replacement and expansion