描述

产品概述

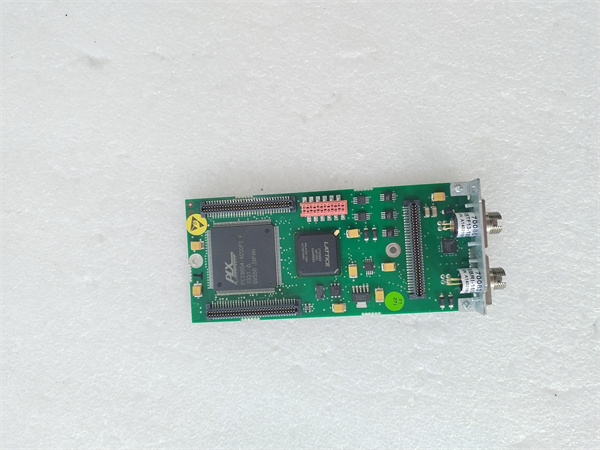

FANUC A860-0326-T103是一款高精度脉冲编码器,属于FANUC数控系统的核心组件,主要用于检测旋转轴的位置、方向和速度,并将机械运动转换为电信号输出。其设计兼顾高分辨率、紧凑结构和工业级可靠性,广泛应用于数控机床、机器人及自动化设备的运动控制。

核心功能特点

高分辨率与精度

支持高分辨率增量编码,能够精确检测旋转轴的微小位移,适用于高精度加工场景(如纳米级轮廓控制)。

内部采用纳米插补技术(AI nanoContour control),通过将微米级指令转换为纳米级输出,提升加工表面质量和精度。

紧凑型设计

体积小巧,适配紧凑型机械结构,便于集成到数控机床主轴、机器人关节等空间受限的设备中。

宽温域与抗干扰能力

工作温度范围:覆盖工业环境常见温度区间,适应高温、低温及多尘环境。

抗电磁干扰(EMI)设计:符合工业级标准,确保信号传输稳定性。

多场景兼容性

支持与FANUC数控系统(如16i*系列)无缝集成,适配预读控制(G08P1)和高精度轮廓控制(G05P10000)功能,优化加工路径与速度曲线。

技术参数

物理规格

结构形式:紧凑型模块化设计,符合工业安装标准。

重量:未明确标注,但推测为轻量化设计(典型编码器重量约0.5-1.5 kg)。

电气性能

输入电压:兼容FANUC数控系统标准电压(如24 V DC)。

输出信号:脉冲信号(A/B相差90°,支持Z相索引脉冲)。

环境适应性

防护等级:IP67(防尘防水),适应恶劣工业环境。

振动耐受性:符合数控机床主轴高振动场景需求。

典型应用场景

数控机床

主轴旋转检测,确保切削精度与同步控制。

工业机器人

关节轴位移监测,实现高精度轨迹跟踪。

自动化生产线

输送带速度与位置反馈,优化生产节拍。

Product Overview

FANUC A860-0326-T103 is a high-precision pulse encoder,which belongs to the core component of the FANUC CNC system.It is mainly used to detect the position,direction and speed of the rotation axis and convert mechanical movement into electrical signal output.Its design takes into account high resolution,compact structure and industrial-grade reliability,and is widely used in motion control of CNC machine tools,robots and automation equipment.

Core functional features

High resolution and accuracy

Supports high-resolution incremental coding,which can accurately detect tiny displacements of the rotation axis,and is suitable for high-precision processing scenarios(such as nano-level contour control).

Nanointerpolation technology(AI nanoContour control)is used internally to improve processing surface quality and accuracy by converting micron-scale instructions into nano-scale output.

Compact design

It is small in size and is suitable for compact mechanical structure,making it easy to integrate into space-constrained equipment such as CNC machine tool spindles and robot joints.

Wide temperature domain and anti-interference ability

Working temperature range:Cover the common temperature range of industrial environments and adapt to high-temperature,low-temperature and dusty environments.

Anti-electromagnetic interference(EMI)design:complies with industrial-grade standards to ensure signal transmission stability.

Multi-scenario compatibility

Supports seamless integration with FANUC CNC systems(such as the 16i*series),adapts to read-pre-control(G08P1)and high-precision profile control(G05P10000)functions,and optimizes machining path and speed curves.

Technical parameters

Physical specifications

Structural form:compact modular design,compliant with industrial installation standards.

Weight:Not explicitly marked,but it is supposed to be a lightweight design(typical encoder weight is about 0.5-1.5 kg).

Electrical performance

Input voltage:Compatible with FANUC CNC system standard voltage(such as 24 V DC).

Output signal:Pulse signal(A/B phase difference is 90°,supporting Z-phase index pulse).

Environmental adaptability

Protection level:IP67(dust-proof and waterproof),adapting to harsh industrial environments.

Vibration resistance:Meets the high vibration scenario requirements of CNC machine tool spindle.

Typical application scenarios

CNC machine tool

Spindle rotation detection ensures cutting accuracy and synchronous control.

Industrial robots

Joint axis displacement monitoring to achieve high-precision trajectory tracking.

Automated production line

Conveyor belt speed and position feedback,optimize production beat.