描述

FCP280 RH924YA产品详情

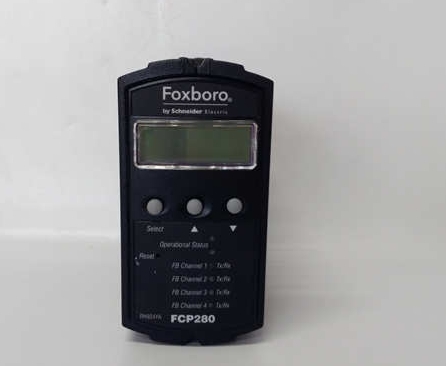

FCP280 RH924YA是Foxboro(福克斯波罗)推出的一款高性能现场控制处理器,广泛应用于工业自动化和过程控制领域。以下是该产品的详细信息:

核心功能与特性:

强大的数据处理和通讯能力:支持复杂控制算法和任务,提供快速响应,可处理高密度工业数据,适用于严苛的控制场景。

高扩展性:支持多达128个紧凑型或标准200系列FBM(现场总线模块),或128个100系列FBM与200系列FBM的组合,无需额外现场总线通信模块。

容错设计:采用双控制模块专利技术,支持冗余操作,显著提升系统可靠性,降低故障停机风险。

自托管模式:即使无主机工作站,仍可基于有效控制数据库自主启动,保障系统独立性。

在线升级功能:支持在线图像容错升级(OLUG),无需中断生产过程即可完成系统更新。

实时监控与诊断:配备液晶显示器(LCD),实时显示字母错误、角色状态和系统参数,支持故障快速定位与处理。

技术参数:

网络连接:通过标准光纤或铜质100 Mbps以太网电缆连接至Mesh控制网络系统,确保稳定可靠的通信。

环境适应性:通过G3等级严苛环境认证,可在极端工业环境下长期稳定运行。

安全认证:通过Archilles Level2和ISASecure EDSA Level1网络安全认证,保障数据传输安全性。

硬件配置:搭载基于ARM的500MHz芯片组,配备128MB SDRAM内存和128MB闪存,支持高速数据处理。

控制性能:功能块执行速度达16,000个/秒,可组态8,000个控制模块,扫描周期覆盖0.05秒至60分钟。

应用领域:

能源行业:用于发电厂、石油天然气上游/中游的连续控制、逻辑控制和顺序控制。

化工与冶金:在精炼、石化、冶金等流程工业中实现数据采集、报警检测和动态优化。

基础设施:支持交通信号系统、楼宇自动化系统的远程监控与智能调度。

环保与水处理:应用于污水处理厂的工艺参数监测与设备联动控制。

系统兼容性:

硬件兼容:与早期Foxboro自动化平台硬件兼容并存,支持无缝升级。

软件集成:支持EXACT(专家自适应控制整定算法)和EXACT MV(多变量控制)等算法,可通过功能控制块灵活配置控制方案。

模块化设计:支持任意CP(控制处理器)模块参数的跨设备连接,满足复杂控制需求。

FCP280 RH924YA Product Details

FCP280 RH924YA is a high-performance field control processor launched by Foxboro,which is widely used in industrial automation and process control.The following is the detailed information of the product:

Core functions and features:

Powerful data processing and communication capabilities:Supports complex control algorithms and tasks,provides fast response,can handle high-density industrial data,and is suitable for demanding control scenarios.

High scalability:Supports up to 128 compact or standard 200 series FBMs(fieldbus modules),or a combination of 128 100 series FBMs and 200 series FBMs,without the need for additional fieldbus communication modules.

Fault-tolerant design:Adopts patented dual control module technology to support redundant operation,significantly improves system reliability,and reduces the risk of downtime due to failures.

Self-hosted mode:Even without a host workstation,it can still start autonomously based on an effective control database to ensure system independence.

Online upgrade function:Supports online image fault-tolerant upgrade(OLUG),and system updates can be completed without interrupting the production process.

Real-time monitoring and diagnosis:equipped with a liquid crystal display(LCD),which displays letter errors,role status and system parameters in real time,and supports rapid fault location and processing.

Technical parameters:

Network connection:connected to the Mesh control network system through a standard optical fiber or copper 100 Mbps Ethernet cable to ensure stable and reliable communication.

Environmental adaptability:Passed the G3 level harsh environment certification and can operate stably and long-term in extreme industrial environments.

Security certification:Passed Archilles Level2 and ISASecure EDSA Level1 network security certification to ensure data transmission security.

Hardware configuration:Equipped with an ARM-based 500MHz chipset,equipped with 128MB SDRAM memory and 128MB flash memory,supporting high-speed data processing.

Control performance:The function block execution speed reaches 16,000/second,8,000 control modules can be configured,and the scan cycle covers 0.05 seconds to 60 minutes.

Application areas:

Energy industry:used for continuous control,logic control and sequential control of power plants,upstream/midstream oil and gas.

Chemical and Metallurgical:Data collection,alarm detection and dynamic optimization in process industries such as refining,petrochemicals,and metallurgy.

Infrastructure:Support remote monitoring and intelligent scheduling of traffic signal systems and building automation systems.

Environmental Protection and Water Treatment:Applied to process parameter monitoring and equipment linkage control in sewage treatment plants.

System Compatibility:

Hardware Compatibility:Compatible and coexistent with the hardware of the early Foxboro automation platform,supporting seamless upgrades.

Software Integration:Supports algorithms such as EXACT(Expert Adaptive Control Setting Algorithm)and EXACT MV(Multivariable Control),and can flexibly configure control schemes through functional control blocks.

Modular Design:Supports cross-device connection of any CP(Control Processor)module parameters to meet complex control requirements.