描述

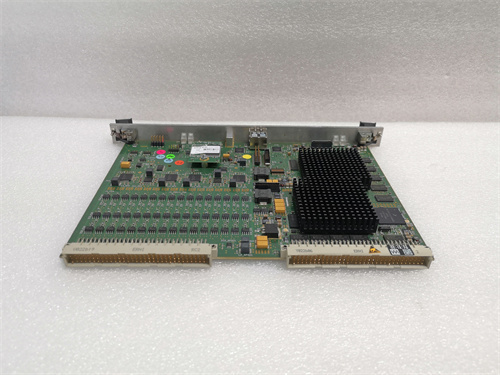

FISHER-ROSEMOUNT KJ2002X1-CA1是一款高性能工业控制器模块,专为复杂工业场景设计,集数据采集、处理与控制功能于一体。以下是其核心功能与技术特点的综合解析:

一、核心功能

数据采集与处理

-支持高精度数据采集,兼容多种传感器和执行器信号,可处理模拟量及数字量输入。

-内置高速处理器与嵌入式系统软件,支持复杂算法(如机器学习、深度学习)及信号滤波,满足实时性要求。

控制执行

-通过定制化控制软件实现电机、阀门等执行机构的精准动作控制,适用于化工、石油、电力等高可靠性需求场景。

通信与集成

-支持多种工业协议(如Modbus、Profinet),可灵活接入DCS、SCADA等系统。

-支持与主流操作系统及第三方应用集成,适应不同工业自动化架构。

二、技术特点

高可靠性与稳定性

-采用冗余设计与容错机制,确保在严苛工业环境中稳定运行。

-工业级防护认证(如IP55),适应高温、高湿及电磁干扰环境。

模块化与灵活性

-紧凑型设计(尺寸未详),支持快速安装与扩展。

-提供多种输入/输出接口,可适配不同传感器与执行器类型。

智能配置与维护

-友好的用户界面支持快速配置,无需复杂编程。

-支持远程诊断与维护,降低停机时间。

三、典型应用领域

化工与石油行业

-用于反应釜温度控制、压力监控及紧急切断阀联动。

电力与能源

-电网设备状态监测、发电机组保护逻辑控制。

制药与食品加工

-生产流程自动化、卫生级设备控制。

智能制造

-工业机器人运动控制、智能物流系统协同。

四、设计优势

低功耗与长寿命:采用节能型处理器,支持长时间无故障运行。

兼容性:无缝对接主流PLC(如西门子、罗克韦尔)及DCS系统。

可扩展性:通过模块堆叠或网络扩展,满足大型项目需求。

FISHER-ROSEMOUNT KJ2002X1-CA1 is a high-performance industrial controller module designed for complex industrial scenarios,integrating data acquisition,processing and control functions.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions

Data acquisition and processing

-Supports high-precision data acquisition,compatible with a variety of sensor and actuator signals,and can process analog and digital inputs.

-Built-in high-speed processor and embedded system software,support complex algorithms(such as machine learning,deep learning)and signal filtering to meet real-time requirements.

Control execution

-Through customized control software,precise motion control of actuators such as motors and valves is achieved,which is suitable for high-reliability demand scenarios such as chemical,petroleum,and electricity.

Communication and integration

-Supports a variety of industrial protocols(such as Modbus,Profinet),and can be flexibly connected to DCS,SCADA and other systems.

-Supports integration with mainstream operating systems and third-party applications to adapt to different industrial automation architectures.

II.Technical features

High reliability and stability

-Adopts redundant design and fault-tolerant mechanism to ensure stable operation in harsh industrial environments.

-Industrial protection certification(such as IP55),adaptable to high temperature,high humidity and electromagnetic interference environment.

Modularity and flexibility

-Compact design(size not specified),supports fast installation and expansion.

-Provides a variety of input/output interfaces,which can adapt to different types of sensors and actuators.

Intelligent configuration and maintenance

-Friendly user interface supports fast configuration without complex programming.

-Supports remote diagnosis and maintenance to reduce downtime.

III.Typical application areas

Chemical and petroleum industry

-Used for reactor temperature control,pressure monitoring and emergency shut-off valve linkage.

Power and energy

-Power grid equipment status monitoring,generator set protection logic control.

Pharmaceutical and food processing

-Production process automation,sanitary equipment control.

Intelligent manufacturing

-Industrial robot motion control,intelligent logistics system collaboration.

IV.Design advantages

Low power consumption and long life:Energy-saving processors are used to support long-term trouble-free operation.

Compatibility:Seamless connection with mainstream PLC(such as Siemens,Rockwell)and DCS systems.

Scalability:Meet the needs of large projects through module stacking or network expansion.