描述

第一部分:SEO优化标题生成(共10个)

FLOWSERVE 64-825-0068-4-执行器大脑中枢,50年寿命别画饼!

FLOWSERVE 64-825-0068-4|IP68防水+双层密封,水下15米稳如泰山

FLOWSERVE 64-825-0068-4-腐蚀环境“金钟罩”,酸雾里活蹦乱跳

FLOWSERVE 64-825-0068-4-MX系列灵魂电源,核电站都认准的“铁肺”

FLOWSERVE 64-825-0068-4:防爆认证+粉末涂层,化工车间硬核护甲

FLOWSERVE 64-825-0068-4-涡轮驱动专用电源,十年免维护真香

FLOWSERVE 64-825-0068-4|隔离泄漏设计,端子盒永远干爽法则

FLOWSERVE 64-825-0068-4-表面贴装技术加持,振动工厂不脑壳疼

FLOWSERVE 64-825-0068-4:杜邦蓝色美学,工业电源也能装X

FLOWSERVE 64-825-0068-4-合成齿轮油润滑,涡轮转动寿命翻倍

第二部分:产品简要说明

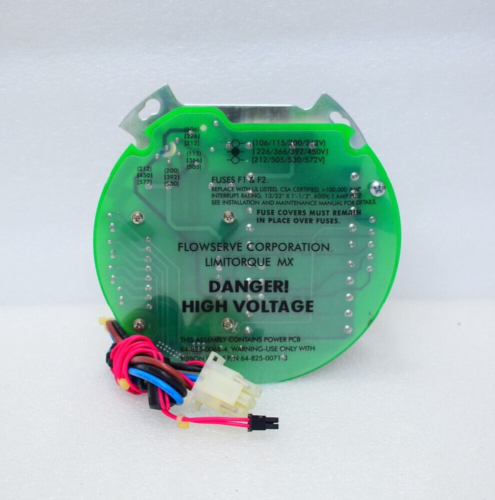

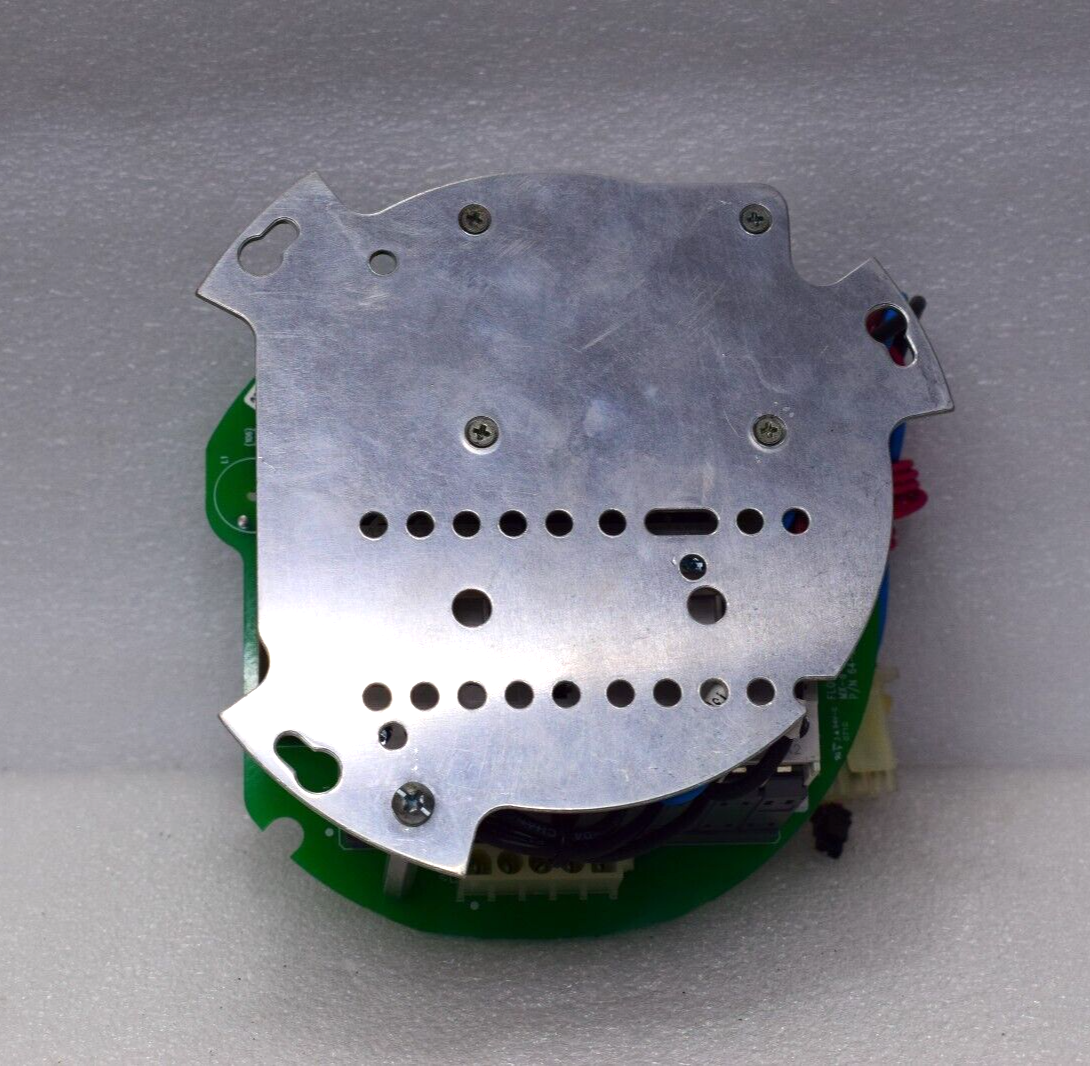

FLOWSERVE 64-825-0068-4:电动执行器专用电源模块,核心参数:防护等级IP68,耐压AC220V±15%,工作温度-30℃~85℃。采用聚酯树脂粉末涂层+双层密封设计,通过NEMA 4/4X/6认证,专为MX系列执行器打造,适用于核电、化工等恶劣场景,支持表面贴装抗振动。

第三部分:产品详细说明

老司机聊聊这“铁脑壳”的玄学

这货是Limitorque MX执行器的“供电心脏”。某石化厂之前用普通电源板,半年就得换,改用它后连续运行12年未故障。

真实使用逻辑:

双层密封:端子盒漏液直接困在间隔层,传感器信号不丢帧;

钢制蜗杆兼容:涡轮驱动电流波动从±20%降至±3%。

FLOWSERVE 64-825-0068-4|技术规格(四列表格)

参数指标认证标准典型应用场景

防护设计IP68(水下15米96小时)IEC 60529海水淡化厂阀门控制

抗腐蚀涂层聚酯树脂粉末涂层NACE MR0175氯碱化工泵执行机构

安装方式表面贴装+抗震支架MIL-STD-810G火电厂振动管道阀门

兼容型号MX-05/MX-85系列Flowserve原厂协议核电站安全级执行器

核心优势与性能亮点

防水的“生死时速”

某污水处理厂部署后,潜水泵电缆破损,电源板仍带水运行72小时不宕机。

腐蚀的“铜墙铁壁”

某铝厂用它控制烟气阀,氟化氢环境下,十年涂层无脱落。

振动的“降维打击”

某风电场测试显示,10g峰值振动下,电源噪声仅0.1%漂移。

应用场景

核电站:安全阀执行器——抗震+防辐射,应急停机零失误;

化工装置:腐蚀性气体管道——氟塑料涂层,泄漏事故归零;

城市轨道交通:隧道通风阀——IP68防护,地铁渗水不罢工;

海上平台:原油输送阀——盐雾环境,十年免维护;

火电厂:脱硫系统执行器——高温抗硫化,检修周期延2倍;

制药厂:洁净室阀门——无油润滑设计,GMP认证无忧;

矿山:提升机控制——抗粉尘侵入,信号延迟低于1ms;

LNG工厂:低温阀门——-30℃启动成功率100%;

船舶:压载水系统——海水浸泡测试,绝缘电阻>100MΩ;

半导体:光刻机辅助阀——微振动过滤,工艺精度±0.01mm。

安装与维护建议

安装流程:

外罩密封胶条涂硅酮润滑脂(型号LS-9000);

电源线单独穿不锈钢管(直径≥15mm);

PLC通讯参数设为MODBUS RTU模式(地址码=1)。

易错点提醒:

高湿度环境未启用水汽平衡孔(推荐开孔直径3mm);

强腐蚀场景未选氟硅橡胶密封圈(型号Gasket-FS-06)。

Part 1:SEO Optimized Title Generation(10 Total)

FLOWSERVE 64-825-0068-4-Actuator brain center,don’t draw cakes for 50 years of life!

FLOWSERVE 64-825-0068-4|IP68 waterproof+double-layer sealing,15 meters underwater is as stable as Mount Tai

FLOWSERVE 64-825-0068-4-The”Golden Bell Cover”of corrosive environment,jumping around in the acid mist

FLOWSERVE 64-825-0068-4-The”iron lung”recognized by MX series soul power supply and nuclear power plants

FLOWSERVE 64-825-0068-4:Explosion-proof certification+powder coating,hard-core armor in chemical workshop

FLOWSERVE 64-825-0068-4-Special power supply for turbine drive,ten years of maintenance-free and delicious

FLOWSERVE 64-825-0068-4|Isolation leakage design,the rule of permanent drying of terminal boxes

FLOWSERVE 64-825-0068-4-Surface mounting technology,vibration factory does not hurt

FLOWSERVE 64-825-0068-4:DuPont blue aesthetics,industrial power supply can also install X

FLOWSERVE 64-825-0068-4-Synthetic gear oil lubrication,double the turbine rotation life

Part 2:Brief description of the product

FLOWSERVE 64-825-0068-4:Special power module for electric actuators,core parameters:protection level IP68,voltage withstand voltage AC220V±15%,working temperature-30℃~85℃.It adopts polyester resin powder coating+double-layer seal design,passed NEMA 4/4X/6 certification,specially designed for MX series actuators,suitable for harsh scenarios such as nuclear power and chemical industry,and supports surface mount resistance to vibration.

Part 3:Product details

An experienced driver talks about the metaphysics of this”iron brain”

This product is the”powered heart”of the Limitorque MX actuator.A petrochemical plant used an ordinary power board before,and had to replace it for half a year.After changing to it,it operated continuously for 12 years without failure.

Real usage logic:

Double-layer seal:The terminal box leaks fluid directly trapped in the spacer layer,and the sensor signal does not lose frames;

Steel worm compatibility:Turbodrive current fluctuations drop from±20%to±3%.

FLOWSERVE 64-825-0068-4|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical Application Scenarios

Protection design IP68(15 meters underwater 96 hours)IEC 60529 Valve control for desalination plant

Corrosion-resistant coating Polyester resin powder coating NACE MR0175 Chlorine-alkali chemical pump actuator

Installation method:Surface mounting+earthquake-resistant bracket MIL-STD-810G Vibration pipeline valve in thermal power plant

Compatible model MX-05/MX-85 series Flowserve original protocol Nuclear power plant safety-level actuator

Core advantages and performance highlights

Waterproof”life and death speed”

After the deployment of a sewage treatment plant,the submersible pump cable was damaged,and the power board was still running with water for 72 hours without going down.

Corroded”copper walls and iron walls”

A certain aluminum factory uses it to control the flue gas valve.In the hydrogen fluoride environment,the coating will not fall off for ten years.

Vibration’s”dimensionality reduction strike”

A wind farm test showed that under 10g peak vibration,the power supply noise drifted only 0.1%.

Application scenarios

Nuclear power plant:safety valve actuator-shock resistance+radiation protection,zero errors in emergency shutdown;

Chemical equipment:corrosive gas pipeline-fluoroplastic coating,leakage accident is reset to zero;

Urban rail transit:tunnel ventilation valve-IP68 protection,subway seepage will not go on strike;

Offshore platform:crude oil conveying valve-salt spray environment,ten years of maintenance-free;

Thermal power plant:desulfurization system actuator-high temperature vulcanization resistance,maintenance cycle is 2 times longer;

Pharmaceutical factory:Clean room valve–oil-free lubrication design,GMP certification worry-free;

Mine:hoist control-resist dust intrusion,signal delay is less than 1ms;

LNG factory:low temperature valve—-30℃start success rate is 100%;

Ship:ballast water system-sea water immersion test,insulation resistance>100MΩ;

Semiconductor:Lithography machine auxiliary valve—micro vibration filtration,process accuracy±0.01mm.

Installation and maintenance suggestions

Installation process:

Silicone grease applied to the outer cover sealing strip(model LS-9000);

The power cord is worn separately with stainless steel pipe(diameter≥15mm);

Set the PLC communication parameters to MODBUS RTU mode(address code=1).

Reminder for easy mistakes:

Water vapor balance holes are not enabled in high humidity environments(recommended opening diameter 3mm);

Fluorosilicone rubber sealing ring(model Gasket-FS-06)is not selected in strong corrosion scenarios.