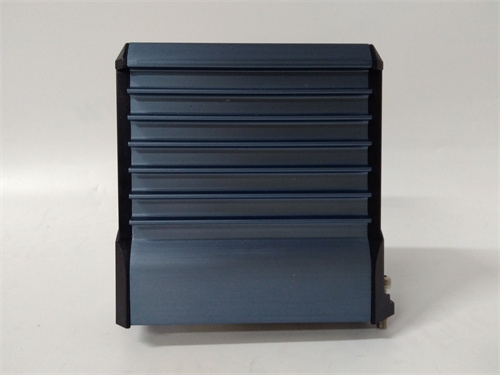

描述

FOXBORO FBM211 P0914TN是福克斯波罗(Foxboro)公司推出的一款高性能数字量输入输出模块,专为工业自动化控制系统设计,广泛应用于电力、化工、机械制造等领域。以下是其核心功能、技术参数及应用场景的综合分析:

1.核心功能与技术参数

输入输出配置:

支持16点数字量输入/输出灵活配置,可独立选择继电器输出(250VAC/30VDC,2A)或晶体管输出(24VDC,0.5A),满足不同负载需求。

隔离性能:

输入/输出间及通道间采用光电隔离技术,通道间隔离电压达2500V,有效抑制噪声干扰,提升系统稳定性。

响应速度:

输入响应时间<1ms,输出响应时间<5ms,适合实时性要求高的控制任务(如工业机器人、高速生产线)。

通信接口:

通过背板总线与PLC主站连接,支持Modbus、以太网等工业协议,兼容Foxboro I/A Series等控制系统。

环境适应性:

工作温度范围-20℃至+60℃,防护等级IP20,适用于室内工业环境,部分型号支持宽温设计(如-40℃至+70℃)。

2.功能特点

高可靠性:

内置过压、过流保护机制,支持冗余设计,平均无故障时间(MTBF)超50,000小时,适合连续运行场景。

灵活扩展:

支持模块级联扩展,最大可扩展至数百个I/O点,适用于复杂控制系统(如分布式发电站、大型制造产线)。

智能诊断:

通过LED指示灯实时显示模块状态(如通信状态、故障类型),并支持上位机远程监控与报警。

兼容性优化:

兼容主流PLC品牌(如Siemens、ABB、GE),可通过编程软件(如Foxboro InTouch)实现逻辑自定义。

3.典型应用场景

电力系统:

用于发电机励磁控制、开关柜状态监测,精准采集断路器位置、继电器动作等数字信号。

化工与制药:

监测工艺设备的启停状态、阀门开闭信号,结合PLC实现流程自动化控制。

机械制造:

集成于数控机床、注塑机控制系统,实时反馈传感器信号(如限位开关、安全门状态),保障设备安全运行。

楼宇自动化:

控制照明、安防系统中的开关信号,实现智能楼宇的集中管理。

FOXBORO FBM211 P0914TN is a high-performance digital input and output module launched by Foxboro.It is designed for industrial automation control systems and is widely used in power,chemical industry,machinery manufacturing and other fields.The following is a comprehensive analysis of its core functions,technical parameters and application scenarios:

1.Core functions and technical parameters

Input and output configuration:

Supports flexible configuration of 16-point digital input/output,and can independently select relay output(250VAC/30VDC,2A)or transistor output(24VDC,0.5A)to meet different load requirements.

Isolation performance:

Optoelectronic isolation technology is used between input/output and channels,and the isolation voltage between channels reaches 2500V,which effectively suppresses noise interference and improves system stability.

Response speed:

Input response time<1ms,output response time<5ms,suitable for control tasks with high real-time requirements(such as industrial robots,high-speed production lines).

Communication interface:

Connected to the PLC master station through the backplane bus,supports industrial protocols such as Modbus and Ethernet,and is compatible with control systems such as Foxboro I/A Series.

Environmental adaptability:

The operating temperature range is-20℃to+60℃,and the protection level is IP20,which is suitable for indoor industrial environments.Some models support wide temperature design(such as-40℃to+70℃).

2.Functional features

High reliability:

Built-in overvoltage and overcurrent protection mechanisms,support redundant design,and mean time between failures(MTBF)exceeds 50,000 hours,which is suitable for continuous operation scenarios.

Flexible expansion:

Supports module cascade expansion,which can be expanded to hundreds of I/O points at most,suitable for complex control systems(such as distributed power stations and large-scale manufacturing production lines).

Intelligent diagnosis:

The module status(such as communication status and fault type)is displayed in real time through LED indicators,and supports remote monitoring and alarm of the host computer.

Compatibility optimization:

Compatible with mainstream PLC brands(such as Siemens,ABB,GE),and logic customization can be achieved through programming software(such as Foxboro InTouch).

3.Typical application scenarios

Power system:

Used for generator excitation control,switch cabinet status monitoring,and accurate collection of digital signals such as circuit breaker position and relay action.

Chemical and pharmaceutical:

Monitor the start and stop status of process equipment and valve opening and closing signals,and combine with PLC to realize process automation control.

Machinery manufacturing:

Integrated in CNC machine tools and injection molding machine control systems,real-time feedback of sensor signals(such as limit switches and safety door status)to ensure safe operation of equipment.

Building automation:

Control the switch signals in lighting and security systems to realize centralized management of smart buildings.