描述

FOXBORO FCP280 RH924YA技术工控解析:高可靠性工业过程控制核心处理器

一、产品概述

FOXBORO FCP280 RH924YA是施耐德电气旗下Foxboro DCS系统的核心控制模块,属于EcoStruxure™Foxboro™DCS系列,专为工业自动化和过程控制设计。其核心功能包括调节、逻辑、时序与顺序控制,支持128个现场总线模块(FBM)扩展,并通过容错设计和在线升级(OLUG)提升系统可靠性与维护效率。该模块适用于化工、电力、石油天然气、制药等行业的复杂控制场景。

二、核心功能与技术特性

1.容错与冗余设计

双模块冗余:采用两个并行运行的控制模块,提供专利容错操作,单模块故障时仍能保持系统运行,可靠性显著提升。

在线升级(OLUG/EOLUG):支持不中断过程的在线图像升级,减少停机时间。

2.高性能通信与扩展能力

现场总线支持:

速率:2Mbps或268Kbps HDLC现场总线速率,兼容光纤/铜缆100Mbps以太网。

模块扩展:最多支持128个200系列FBM,或128个100/200系列混合FBM(100系列限64个)。

网络适配:通过标准光纤或铜缆连接控制网络,支持网状拓扑和GPS时间同步。

3.数据处理与控制功能

多任务处理:支持梯形图逻辑、电机驱动控制器(MDACT)和分布式PID控制(DPIDA),满足高速控制需求。

实时监控:配备LCD显示屏,实时显示错误信息与系统状态。

4.环境适应性

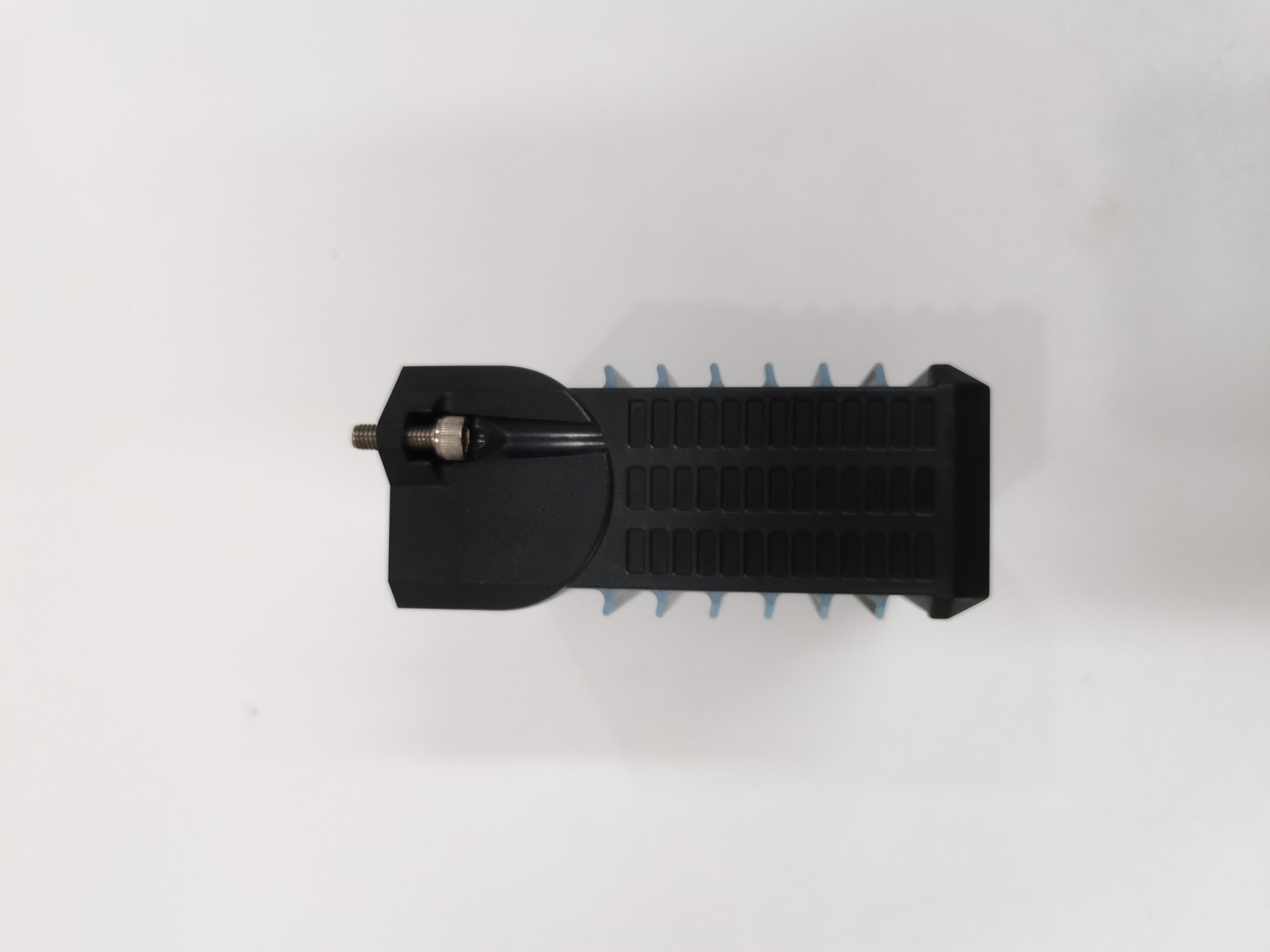

工业级防护:压铸铝外壳,通过CE认证,适应G3级恶劣环境(高温、振动、粉尘)。

电源与功耗:支持宽电压输入,功耗低至5W以下(部分场景)。

三、典型应用场景

化工生产

控制反应釜温度、压力及物料输送,确保工艺参数稳定。

电力系统

监控发电机运行状态,优化电网调度与设备保护。

石油天然气

管道压力监测、炼化过程自动化控制。

制药与食品加工

精确控制药品生产流程与食品包装生产线。

FOXBORO FCP280 RH924YA Technical Industrial Control Analysis:High Reliability Industrial Process Control Core Processor

1.Product Overview

FOXBORO FCP280 RH924YA is the core control module of Schneider Electric’s Foxboro DCS system.It belongs to the EcoStruxure™Foxboro™DCS series,designed for industrial automation and process control.Its core functions include adjustment,logic,timing and sequential control,support 128 fieldbus modules(FBM)expansion,and improve system reliability and maintenance efficiency through fault-tolerant design and online upgrade(OLUG).This module is suitable for complex control scenarios in chemical,electricity,oil and gas,pharmaceutical and other industries.

2.Core functions and technical characteristics

1.Fault-tolerant and redundant design

Dual-module redundancy:Two parallel operation control modules are adopted to provide patented fault-tolerant operation.The system can still be maintained when a single module fails,and the reliability is significantly improved.

Online Upgrade(OLUG/EOLUG):Supports online image upgrades that do not interrupt the process to reduce downtime.

2.High-performance communication and expansion capabilities

Fieldbus support:

Rate:2Mbps or 268Kbps HDLC fieldbus rate,compatible with fiber/copper cable 100Mbps Ethernet.

Module extension:Supports up to 128 200 series FBMs,or 128 100/200 series hybrid FBMs(100 series limited to 64).

Network adaptation:Control the network through standard fiber or copper cable connection,supporting mesh topology and GPS time synchronization.

3.Data processing and control functions

Multitasking:supports ladder logic,motor drive controller(MDACT)and distributed PID control(DPIDA)to meet high-speed control needs.

Real-time monitoring:equipped with an LCD display to display error messages and system status in real time.

4.Environmental adaptability

Industrial-grade protection:die-cast aluminum shell,passed CE certification,adapting to harsh G3 environments(high temperature,vibration,dust).

Power and power consumption:Supports wide voltage input,power consumption as low as below 5W(some scenarios).

3.Typical application scenarios

Chemical production

Control the temperature,pressure and material conveying of the reactor to ensure stable process parameters.

Power system

Monitor the generator operating status and optimize grid scheduling and equipment protection.

Oil and gas

Pipeline pressure monitoring and refining process automation control.

Pharmaceutical and food processing

Accurately control the pharmaceutical production process and food packaging production line.