描述

产品简要说明

GE Alstom SCN666是通用电气(GE)与阿尔斯通(Alstom)联合开发的工业级控制模块,核心特性包括:

功能定位:专为轨道交通牵引系统、高精度运动控制及复杂工业场景设计

工业兼容性:支持EtherCAT、Profinet等工业通信协议

环境适应性:工业级防护等级IP67,工作温度范围-40°C~+70°C

扩展能力:支持DIN导轨安装,兼容GE/Alstom双品牌系统生态

产品详细说明

1.硬件架构与核心功能

模块类型

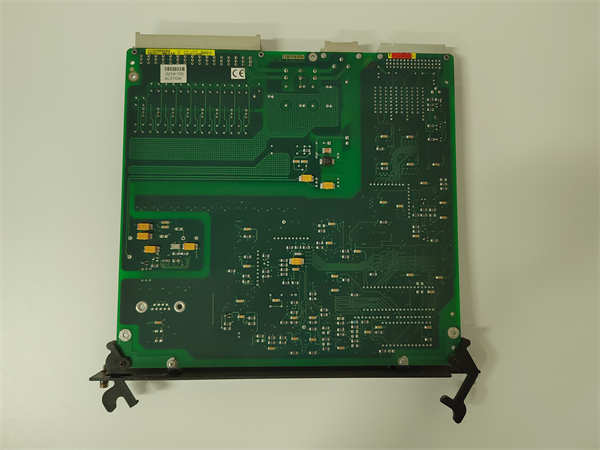

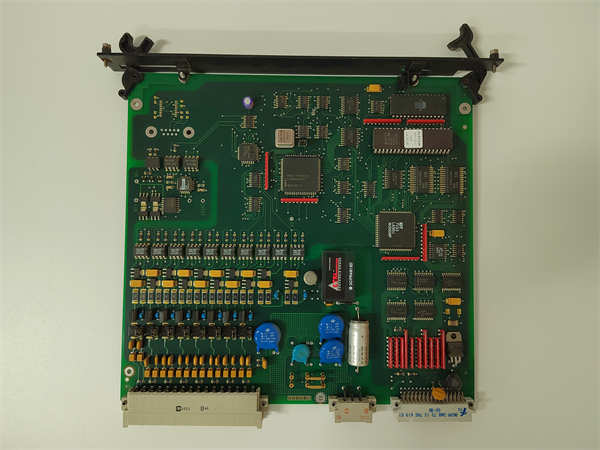

PCB设计:航空级多层板,耐高温(150℃短时承受)

功能分区:

运动控制单元:集成双核Cortex-A53处理器,支持实时运动轨迹规划

通信接口:EtherCAT主站、Profinet IRT、双路光纤通信(100Mbps)

电源管理:冗余24V DC输入,支持宽电压范围(18-36V DC)

安全机制

故障诊断:实时监测电机过载、编码器断线等异常

冗余设计:双通道通信备份,单点故障自动切换

产品概述:GE Alstom SCN666

作为轨道交通与重工业控制领域的旗舰产品,其核心价值体现在极端环境适应性与精密控制能力:

技术价值:

在地铁牵引系统中实现±0.05mm级定位精度

在风电变流器中支持±0.1Hz频率同步

行业适配:

轨道交通:列车牵引逆变器控制、信号系统冗余备份

能源电力:高压直流输电(HVDC)换流站控制

智能制造:精密注塑机压力闭环控制

技术规格:GE Alstom SCN666

参数项规格描述

模块类型工业级运动控制模块

接口类型EtherCAT(主站)、Profinet IRT、光纤通信(双通道)、数字I/O(32点DI/DO)

工作电压24V DC(18-36V DC输入范围)

工作温度-40°C~+70°C

防护等级IP67(防尘防水)

通信协议EtherCAT、Profinet IRT、Modbus TCP

核心价值与性能亮点

1.极端环境可靠性

技术优势:

通过MIL-STD-810G军用级振动测试

-40°C低温启动无需预热

应用案例:某极地科考站实现-45°C环境下的设备连续运行

2.超低延迟控制

技术优势:

通信延迟<50μs(EtherCAT协议)

多轴同步误差<100ns

价值体现:某半导体晶圆切割机实现0.1μm级切削精度

AH116-2

AH116-2

Product brief description

GE Alstom SCN666 is an industrial-grade control module jointly developed by General Electric and Alstom.The core features include:

Functional positioning:designed for rail transit traction systems,high-precision motion control and complex industrial scenarios

Industrial compatibility:Supports industrial communication protocols such as EtherCAT and Profinet

Environmental adaptability:industrial-grade protection grade IP67,working temperature range-40°C~+70°C

Expansion capability:Support DIN rail installation,compatible with GE/Alstom dual brand system ecosystem

Product details

1.Hardware architecture and core functions

Module Type

PCB design:aviation-grade multi-layer board,high temperature resistance(150℃short-term bearing)

Functional partition:

Motion control unit:Integrated dual-core Cortex-A53 processor,supports real-time motion trajectory planning

Communication interface:EtherCAT master station,Profinet IRT,dual fiber optic communication(100Mbps)

Power management:Redundant 24V DC input,support wide voltage range(18-36V DC)

Security mechanism

Fault diagnosis:Real-time monitoring of motor overload,encoder disconnection and other abnormalities

Redundant design:dual-channel communication backup,single point of failure automatic switching

Product Overview:GE Alstom SCN666

As a flagship product in the field of rail transit and heavy industry control,its core value is reflected in extreme environmental adaptability and precision control capabilities:

Technical value:

Achieve±0.05mm positioning accuracy in subway traction system

Supports±0.1Hz frequency synchronization in wind power converters

Industry adaptation:

Rail Transit:Train traction inverter control,signal system redundant backup

Energy and electricity:High voltage DC transmission(HVDC)converter station control

Intelligent manufacturing:precision injection molding machine pressure closed-loop control

Technical Specifications:GE Alstom SCN666

Parameters Specification Description

Module type Industrial grade motion control module

Interface type EtherCAT(main),Profinet IRT,fiber optic communication(dual channel),digital I/O(32-point DI/DO)

Operating voltage 24V DC(18-36V DC input range)

Working temperature-40°C~+70°C

Protection level IP67(dust-proof and waterproof)

Communication Protocols EtherCAT,Profinet IRT,Modbus TCP

Core Valuesand Performance Highlights

1.Extreme environmental reliability

Technical Advantages:

Passed the MIL-STD-810G military-grade vibration test

-40°C low temperature start without preheating required

Application case:A polar scientific research station realizes continuous operation of equipment under-45°C environment

2.Ultra-low latency control

Technical Advantages:

Communication delay<50μs(EtherCAT protocol)

Multi-axis synchronization error<100ns

Value manifestation:A semiconductor wafer cutting machine achieves cutting accuracy of 0.1μm level