描述

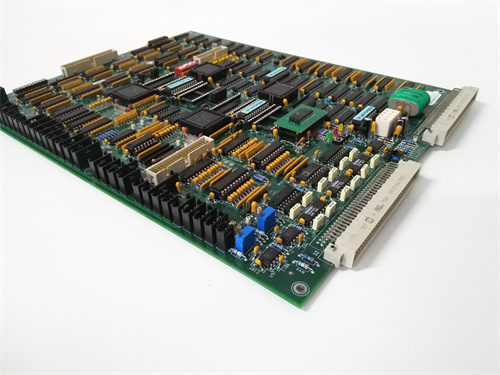

GE DFP100是一款多功能工业自动化设备,集保护、控制、计量和监控功能于一体,广泛应用于配电馈线保护及工业控制系统。以下是其核心功能与技术特点的综合解析:

一、核心功能与应用

配电馈线保护

DFP100是数字馈线继电器,针对配电系统提供全面保护,包括:

-过电流保护:支持低/高设置过电流及定向过电流保护。

-电压与频率保护:具备欠压、过压、欠频、过频保护功能。

-断路器失灵保护:防止断路器拒动引发的故障扩散。

-冷负荷拾取:支持重合闸功能(可选四次重合器)。

控制与监控

-可配置输入/输出:支持自定义逻辑控制,适用于备用母线、变压器线路保护等场景。

-故障定位与记录:提供200条事件记录及I/V波形捕获功能,便于故障分析。

-断路器健康监测:实时评估断路器状态,预防潜在故障。

计量与数据管理

-电能计量:支持AVW(视在功率)、var(无功功率)、Hz(频率)等参数计量。

-需量电流表:记录瞬时电流峰值,优化能源管理。

二、技术参数与性能

输入/输出通道:16路数字输入+16路数字输出(扩展模块可选)。

通信接口:RS-485、以太网、光纤接口,支持远程配置与数据传输。

编程语言:支持梯形图(Ladder Logic)及功能块图(Function Block Diagram)。

工作环境:

-温度:-10°C至60°C(工作),-40°C至70°C(存储)。

-电压范围:100~240V AC输入,12V DC输出。

三、人机交互与扩展性

用户界面:

-10个目标/警报LED指示灯,直观显示设备状态。

-可选配显示器和键盘,支持本地操作。

-RS232/RS485接口,兼容远程上位机管理。

模块化设计:

支持与其他GE自动化组件(如DCS系统、PLC模块)集成,形成统一控制平台。

四、适用场景

电力行业:变电站馈线保护、备用母线监控。

工业制造:生产线配电系统、大功率电机驱动保护。

能源领域:光伏电站、储能系统故障隔离与管理。

smart

GE DFP100 is a multifunctional industrial automation device that integrates protection,control,metering and monitoring functions.It is widely used in distribution feeder protection and industrial control systems.The following is a comprehensive analysis of its core functions and technical features:

I.Core functions and applications

Distribution feeder protection

DFP100 is a digital feeder relay that provides comprehensive protection for distribution systems,including:

-Overcurrent protection:supports low/high setting overcurrent and directional overcurrent protection.

-Voltage and frequency protection:has undervoltage,overvoltage,underfrequency,and overfrequency protection functions.

-Circuit breaker failure protection:prevents the spread of faults caused by circuit breaker refusal.

-Cold load pickup:supports reclosing function(four-time recloser is optional).

Control and monitoring

-Configurable input/output:supports custom logic control,suitable for scenarios such as backup busbar and transformer line protection.

-Fault location and recording:provides 200 event records and I/V waveform capture function for easy fault analysis.

-Circuit breaker health monitoring:Real-time evaluation of circuit breaker status to prevent potential failures.

Metering and data management

-Electric energy metering:Supports AVW(apparent power),var(reactive power),Hz(frequency)and other parameter metering.

-Demand current meter:Record instantaneous current peak value to optimize energy management.

2.Technical parameters and performance

Input/output channels:16 digital inputs+16 digital outputs(optional expansion modules).

Communication interface:RS-485,Ethernet,fiber optic interface,support remote configuration and data transmission.

Programming language:Supports ladder logic and function block diagram.

Working environment:

-Temperature:-10°C to 60°C(operating),-40°C to 70°C(storage).

-Voltage range:100~240V AC input,12V DC output.

3.Human-computer interaction and scalability

User interface:

-10 target/alarm LED indicators,intuitively displaying the device status.

-Optional display and keyboard,support local operation.

-RS232/RS485 interface,compatible with remote host computer management.

Modular design:

Supports integration with other GE automation components(such as DCS system,PLC module)to form a unified control platform.

4.Applicable scenarios

Power industry:substation feeder protection,backup bus monitoring.

Industrial manufacturing:production line distribution system,high-power motor drive protection.

Energy field:photovoltaic power station,energy storage system fault isolation and management.