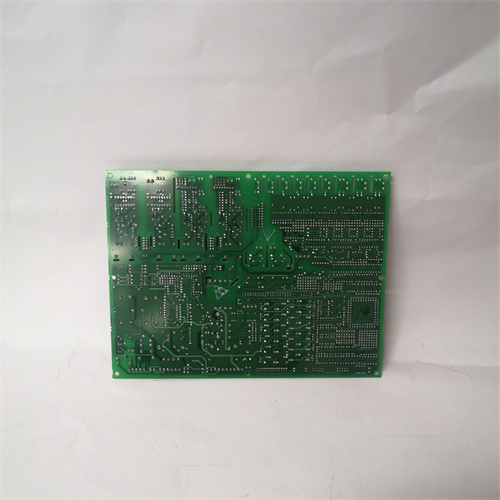

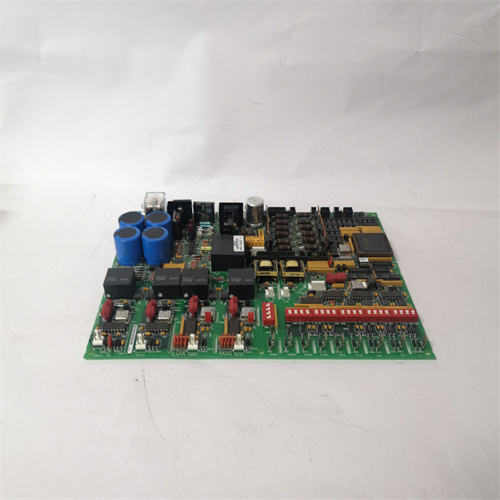

描述

GE DS200ADGIH1AAA产品详情

一、基本信息

品牌:GE(通用电气,工业自动化与驱动系统领域核心供应商,现属GE Vernova业务板块)

型号:DS200ADGIH1AAA

类型:模拟量输入/输出接口模块(Analog Input/Output Interface Module)

用途:作为GE Speedtronic Mark V/Mark VI控制系统的关键组件,用于燃气轮机、蒸汽轮机、发电机组等能源设备的模拟信号采集与控制,适用于电力、石油天然气、船舶推进等场景。

二、技术规格

核心功能

模拟量输入通道:

支持8通道模拟量输入,兼容电压(±10V)、电流(4-20mA)信号。

分辨率:16位(AD转换),精度±0.1%(满量程),采样率100Hz/通道(典型值)。

内置滤波器(可配置截止频率),抑制高频噪声干扰。

模拟量输出通道:

支持4通道模拟量输出,电压(±10V)、电流(0-20mA/4-20mA)可选。

分辨率:12位(DA转换),精度±0.2%(满量程),响应时间<10ms。

信号隔离:

通道间隔离(耐压≥1.5kV),避免信号串扰;输入/输出与电源隔离(耐压≥2.5kV)。

硬件参数

接口类型:

现场信号连接:采用可拆卸端子块(兼容Phoenix Contact或GE专用端子),支持带电插拔。

通信接口:通过GE专用的VME总线或IONet光纤环网与控制器通信,传输延迟<5ms。

电源要求:

模块供电:24VDC(±10%),典型功耗<10W。

信号供电:独立电源或共享模块电源(依配置选择)。

防护等级:IP20(控制柜内安装),模块表面涂层符合NEMA 4X标准(防腐蚀)。

性能指标

响应时间:

模拟量输入:采样周期<10ms(8通道并行采集),支持实时触发(如事件记录)。

模拟量输出:更新周期<5ms,支持快速闭环控制(如压力调节)。

故障检测:

输入通道开路/短路检测时间<2ms,输出通道过流/过压保护时间<1ms。

支持自诊断与报警输出(通过LED指示灯与控制器通信)。

环境适应性:

工作温度:-20℃至+60℃(标准版),-40℃至+70℃(宽温版可选)。

抗振动:符合IEC 60068-2-6标准(10-500Hz,5G)。

三、应用领域

电力行业

燃气轮机控制:采集燃料压力、温度信号,输出控制信号调节燃料阀开度,实现负荷与转速的闭环控制。

发电机励磁系统:通过模拟量输出控制励磁电流,维持发电机端电压稳定。

石油天然气

压缩机控制:采集入口压力、排气温度信号,输出控制信号调节防喘振阀,避免压缩机喘振。

海上平台:通过IP67防护罩(需外配)与冗余通信,适应恶劣海洋环境。

船舶推进

柴油发电机组:监测转速、扭矩信号,输出控制信号调节燃油喷射量,优化燃油效率。

四、产品优势

高精度与可靠性

16位AD/12位DA转换:确保信号采集与输出的高精度,适用于需要精细控制的场景(如压力调节、温度控制)。

隔离设计:通道间与电源隔离,避免信号干扰,提升系统稳定性。

灵活性与兼容性

混合信号支持:单模块集成输入/输出功能,减少机架空间占用。

通信冗余:支持IONet光纤环网,单点故障不影响系统运行。

易用性与维护性

带电插拔:端子块支持热插拔,便于现场维护。

自诊断功能:通过LED指示灯快速定位故障,减少停机时间。

GE DS200ADGIH1AAA Product Details

I.Basic Information

Brand:GE(General Electric,a core supplier in the field of industrial automation and drive systems,now part of the GE Vernova business segment)

Model:DS200ADGIH1AAA

Type:Analog Input/Output Interface Module

Purpose:As a key component of the GE Speedtronic Mark V/Mark VI control system,it is used for analog signal acquisition and control of energy equipment such as gas turbines,steam turbines,and generator sets,and is suitable for power,oil and gas,and ship propulsion.

II.Technical Specifications

Core Functions

Analog Input Channels:

Supports 8-channel analog input,compatible with voltage(±10V)and current(4-20mA)signals.

Resolution:16-bit(AD conversion),accuracy±0.1%(full scale),sampling rate 100Hz/channel(typical value).

Built-in filter(configurable cutoff frequency)to suppress high-frequency noise interference.

Analog output channel:

Supports 4-channel analog output,voltage(±10V),current(0-20mA/4-20mA)optional.

Resolution:12 bits(DA conversion),accuracy±0.2%(full scale),response time<10ms.

Signal isolation:

Channel isolation(withstand voltage≥1.5kV)to avoid signal crosstalk;input/output and power supply isolation(withstand voltage≥2.5kV).

Hardware parameters

Interface type:

Field signal connection:Use removable terminal blocks(compatible with Phoenix Contact or GE dedicated terminals),support live plugging and unplugging.

Communication interface:Communicate with the controller through GE’s dedicated VME bus or IONet optical fiber ring network,with a transmission delay of<5ms.

Power requirements:

Module power supply:24VDC(±10%),typical power consumption<10W.

Signal power supply:independent power supply or shared module power supply(selected by configuration).

Protection level:IP20(installed in the control cabinet),the module surface coating complies with the NEMA 4X standard(anti-corrosion).

Performance indicators

Response time:

Analog input:sampling cycle<10ms(8-channel parallel acquisition),support real-time triggering(such as event recording).

Analog output:update cycle<5ms,support fast closed-loop control(such as pressure regulation).

Fault detection:

Input channel open circuit/short circuit detection time<2ms,output channel overcurrent/overvoltage protection time<1ms.

Support self-diagnosis and alarm output(communication with the controller through LED indicator).

Environmental adaptability:

Operating temperature:-20℃to+60℃(standard version),-40℃to+70℃(wide temperature version optional).

Vibration resistance:in accordance with IEC 60068-2-6 standard(10-500Hz,5G).

III.Application field

Power industry

Gas turbine control:collect fuel pressure and temperature signals,output control signals to adjust the fuel valve opening,and realize closed-loop control of load and speed.

Generator excitation system:control the excitation current through analog output to maintain the stability of the generator terminal voltage.

Oil and gas

Compressor control:collect inlet pressure and exhaust temperature signals,output control signals to adjust the anti-surge valve to avoid compressor surge.

Offshore platform:through IP67 protective cover(external)and redundant communication,adapt to harsh marine environment.

Ship propulsion

Diesel generator set:monitor speed and torque signals,output control signals to adjust fuel injection amount,and optimize fuel efficiency.

IV.Product advantages

High precision and reliability

16-bit AD/12-bit DA conversion:ensure high precision of signal acquisition and output,suitable for scenarios requiring fine control(such as pressure regulation,temperature control).

Isolation design:isolation between channels and power supply to avoid signal interference and improve system stability.

Flexibility and compatibility

Mixed signal support:single module integrates input/output functions to reduce rack space occupation.

Communication redundancy:supports IONet fiber ring network,single point failure does not affect system operation.

Ease of use and maintainability

Hot plugging:terminal blocks support hot plugging for easy on-site maintenance.

Self-diagnosis function:quickly locate faults through LED indicators to reduce downtime.