描述

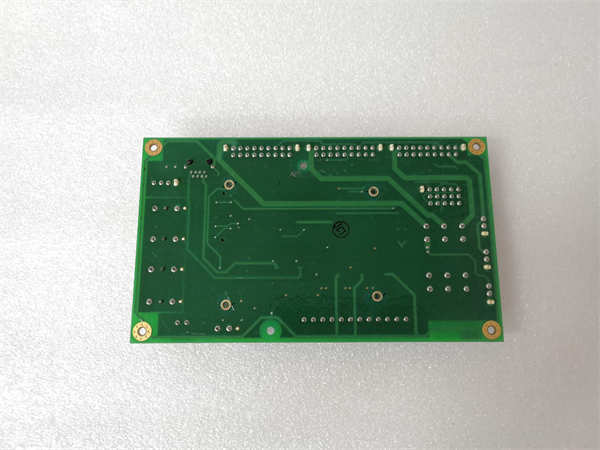

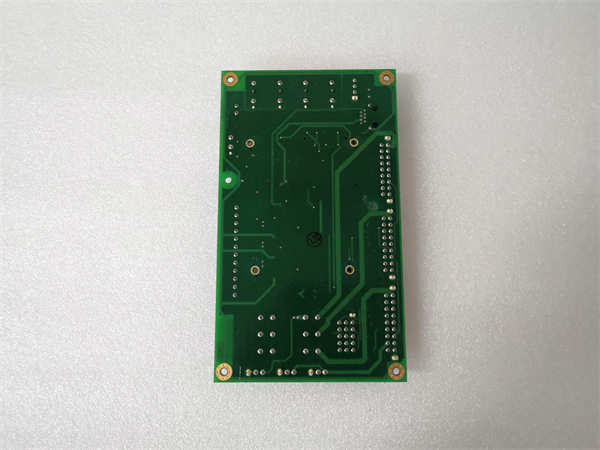

GE DS200LPPAG1AAA技术工控解析:线路保护与智能监控核心模块

一、产品概述

GE DS200LPPAG1AAA是通用电气(GE)Mark V系列中的线路保护面板,专为工业自动化系统设计,主要用于监控、控制及保护电气线路,预防过载、短路、接地故障等电气故障,确保电力系统的安全稳定运行。该模块采用模块化设计,支持灵活扩展与定制,广泛应用于工业、能源、交通、建筑等领域。

二、核心功能与技术参数

1.核心功能

线路保护:具备过载、短路、接地故障等保护功能,通过实时监测电流、电压等参数,自动触发保护机制,防止设备损坏。

智能监控:通过面板上的指示灯与显示屏实时显示线路状态,支持诊断工具生成健康报告,便于快速定位故障。

模块化扩展:支持7个跳线(JP1-JP7)与2个端子块(各3个终端),可灵活配置信号连接与功能扩展。

2.技术参数

参数值

输入电压200-600 VAC

处理器32位高性能微处理器(支持快速数据处理与控制指令执行)

内存大容量内存(支持复杂控制算法与多任务处理)

I/O接口模拟量输入/输出、数字量输入/输出(支持传感器与执行器连接)

通信协议EtherCAT、Profinet、DeviceNet(支持工业以太网与上位机通信)

工作环境宽温范围(-25°C至+60°C),适应工业恶劣环境

电源要求支持220V/380V输入,具备过压、过流保护功能

三、技术优势分析

1.高可靠性设计

材料与工艺:采用高品质材料与严格生产工艺,平均无故障时间(MTBF)超10万小时。

抗干扰能力:通道间电隔离设计,共模抑制比>100 dB,确保信号稳定。

2.智能化与扩展性

诊断功能:通过驱动器内置的诊断工具生成健康报告,支持文件下载与修复前后对比。

模块化接口:支持EtherCAT、Profinet等工业协议,可无缝集成其他设备。

3.安装与维护

安装方式:板卡式设计,安装在驱动器隔板上,兼容控制室安装与工业柜体集成。

维护便捷:支持热插拔,断电后可快速更换模块,减少停机时间。

DS200RT8AG3AHC

DS200RT8AG3AHC

GE DS200LPPAG1AAA technical industrial control analysis:line protection and intelligent monitoring core module

1.Product Overview

GE DS200LPPAG1AAA is a line protection panel in the General Electric(GE)Mark V series.It is specially designed for industrial automation systems.It is mainly used to monitor,control and protect electrical circuits,prevent electrical faults such as overload,short circuit,grounding faults,and ensure the safe and stable operation of the power system.This module adopts a modular design,supports flexible expansion and customization,and is widely used in industries,energy,transportation,construction and other fields.

2.Core functions and technical parameters

1.Core functions

Line protection:It has protection functions such as overload,short circuit,grounding fault,etc.It automatically triggers the protection mechanism by monitoring current and voltage parameters in real time to prevent equipment damage.

Intelligent monitoring:Real-time display of line status through the indicator lights and display on the panel,supporting diagnostic tools to generate health reports,which facilitates rapid locating of faults.

Modular expansion:supports 7 jumpers(JP1-JP7)and 2 terminal blocks(3 terminals each),allowing flexible configuration of signal connections and function expansion.

2.Technical parameters

Parameter Value

Input voltage 200-600 VAC

Processor 32-bit high-performance microprocessor(supports rapid data processing and control command execution)

Memory Large capacity memory(supports complex control algorithms and multitasking)

I/O interface:Analog input/output,digital input/output(supports the connection between sensor and actuator)

Communication protocols EtherCAT,Profinet,DeviceNet(supports industrial Ethernet and upper computer communication)

Working environment Wide temperature range(-25°C to+60°C),adapting to industrial harsh environments

Power supply requirements:Supports 220V/380V input,with overvoltage and overcurrent protection functions

3.Analysis of technical advantages

1.High reliability design

Materials and process:High-quality materials and strict production processes are adopted,with an average failure-free time(MTBF)of more than 100,000 hours.

Anti-interference capability:electrical isolation between channels,common mode rejection ratio>100 dB,ensuring signal stability.

2.Intelligence and scalability

Diagnostic function:Generate health reports through the built-in diagnostic tools of the drive,supporting comparisons between file download and repair.

Modular interface:supports industrial protocols such as EtherCAT and Profinet,allowing seamless integration of other devices.

3.Installation and maintenance

Installation method:Plate-type design,installed on the drive partition,compatible with control room installation and integrated with industrial cabinet.

Convenient maintenance:supports hot swapping,and can quickly replace modules after power outage to reduce downtime.