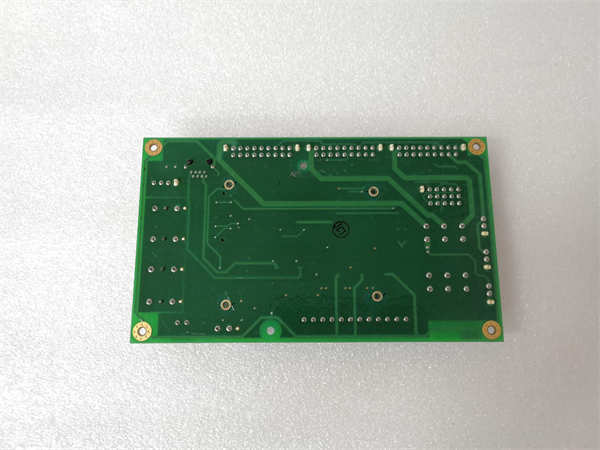

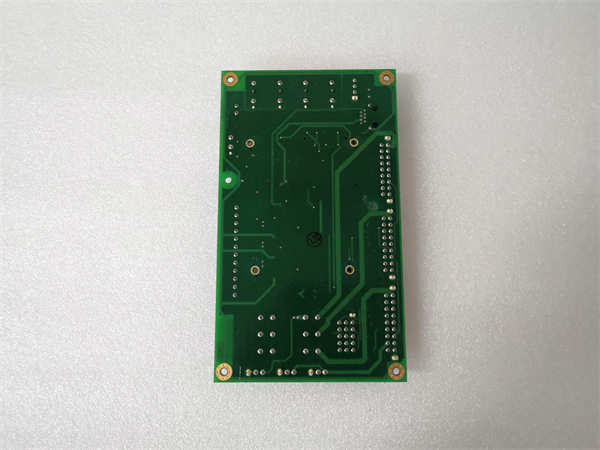

描述

GE DS200PCCAG1ACB是通用电气(GE)旗下的一款高性能处理器模块,专为工业自动化和过程控制领域设计,广泛应用于发电、能源管理及复杂工业系统。以下是其核心功能、技术参数及应用场景的综合概述:

一、核心功能与特点

中央处理单元

-作为控制系统的核心,负责执行控制逻辑、数据处理及系统通信任务,是工业自动化系统的“大脑”。

-高性能计算:支持复杂控制算法与实时数据处理,满足发电、能源管理等高负载场景需求。

-冗余与可靠性:支持冗余配置,确保在单模块故障时系统仍能稳定运行,提升可用性。

-模块化设计:便于安装与维护,支持快速更换,降低停机时间。

通信能力

-集成多种通信接口(如以太网、串行接口),可与传感器、执行器及上位机无缝连接。

-支持工业协议标准,增强系统兼容性。

二、技术参数

处理能力:搭载高性能处理器,支持快速控制策略执行。

存储容量:配备充足存储空间,用于程序存储、操作系统及运行数据。

电源要求:需24V DC供电,确保稳定工作。

工作温度:-40°C至+70°C,适应严苛工业环境。

三、应用场景

发电与能源管理

-在发电控制系统中处理发电机数据,优化运行效率并保障安全。

工业自动化

-执行PLC控制逻辑,支持机械制造、化工等领域的自动化流程。

数据监控与分析

-实时采集传感器数据,实现对工业设备的远程监控与故障诊断。

四、维护与更换

故障诊断:通过指示灯或系统报警提示异常,便于快速定位问题。

更换步骤:需断电操作,佩戴防静电装备,遵循制造商指南以避免硬件损坏。

DS200RT8AG3AHC

DS200RT8AG3AHC

GE DS200PCCAG1ACB is a high-performance processor module from General Electric(GE),designed for industrial automation and process control,and widely used in power generation,energy management and complex industrial systems.The following is a comprehensive overview of its core functions,technical parameters and application scenarios:

I.Core functions and features

Central processing unit

-As the core of the control system,it is responsible for executing control logic,data processing and system communication tasks,and is the”brain”of the industrial automation system.

-High performance computing:supports complex control algorithms and real-time data processing to meet the needs of high-load scenarios such as power generation and energy management.

-Redundancy and reliability:supports redundant configuration to ensure that the system can still operate stably when a single module fails,thereby improving availability.

-Modular design:easy to install and maintain,supports rapid replacement,and reduces downtime.

Communication capabilities

-Integrates multiple communication interfaces(such as Ethernet and serial interfaces),and can be seamlessly connected to sensors,actuators and host computers.

-Supports industrial protocol standards to enhance system compatibility.

II.Technical parameters

Processing capabilities:Equipped with a high-performance processor,it supports rapid control strategy execution.

Storage capacity:Equipped with sufficient storage space for program storage,operating system and running data.

Power supply requirements:24V DC power supply is required to ensure stable operation.

Operating temperature:-40°C to+70°C,suitable for harsh industrial environments.

III.Application scenarios

Power generation and energy management

-Process generator data in power generation control systems to optimize operating efficiency and ensure safety.

Industrial automation

-Execute PLC control logic to support automation processes in mechanical manufacturing,chemical industry and other fields.

Data monitoring and analysis

-Real-time collection of sensor data to achieve remote monitoring and fault diagnosis of industrial equipment.

IV.Maintenance and replacement

Fault diagnosis:Abnormalities are prompted by indicator lights or system alarms to facilitate quick problem location.

Replacement steps:Power off,wear anti-static equipment,and follow manufacturer guidelines to avoid hardware damage.