描述

产品概述

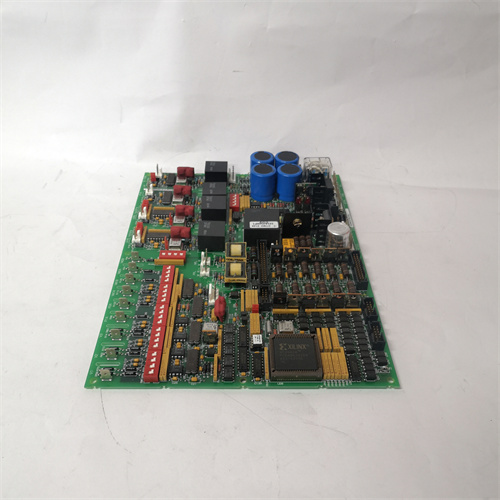

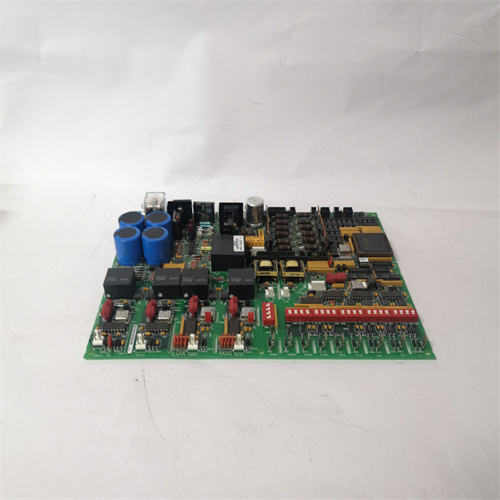

GE DS200SDCCG1AEC是通用电气(GE)旗下Mark V DS200系列的驱动控制卡,专为涡轮机控制系统设计,用于精确控制和监控GE驱动器,确保工业设备的稳定高效运行。其核心功能包括多处理器协同、通信协议支持及故障诊断能力,广泛应用于电力、能源、自动化生产线等领域。

核心功能与技术参数

1.硬件架构

处理器与存储:

集成3个微处理器和共享RAM,支持多任务并行处理,提升控制响应速度。

LED指示灯:

板载10个LED指示灯,按顺序闪烁表示正常运行;

缓慢闪烁:指示错误代码1-399;

快速闪烁:指示错误代码400-1023。

2.通信与扩展

协议支持:

兼容多种工业通信协议(具体协议未明确列出,但强调“可靠高效的性能设计”)。

接口:

支持串行通信接口,可将诊断数据下载至笔记本电脑进行分析。

3.故障诊断与维护

诊断工具:

提供板载测试点(金属柱),需通过专业设备检测信号路径;

驱动器内置诊断工具可访问,支持性能分析与错误定位。

维护要求:

测试需由经过培训的人员执行,设备需校准且符合安全规范。

4.物理规格

尺寸与重量:

参考同系列控制器模块,宽度约119 mm(沿DIN导轨测量),重量约1.2 kg(含包装)。

应用场景

电力与能源:

控制燃气轮机、发电设备的驱动系统,优化能源效率。

工业自动化:

管理自动化生产线中的驱动设备,确保精确运行。

过程控制:

在冶金、化工、水处理等行业中协调多设备协同工作。

关键特性

高可靠性:

专为工业环境设计,支持长期稳定运行,适用于严苛工况。

模块化设计:

可与GE系列其他模块(如模拟量输入/输出模块)集成,扩展功能。

安全性:

内置保护机制,降低故障风险,确保控制系统稳定性。

Product Overview

GE DS200SDCCG1AEC is a driving control card for the Mark V DS200 series of GE’s(GE)’s Mark V DS200 series.It is designed for turbine control systems to accurately control and monitor GE drivers to ensure stable and efficient operation of industrial equipment.Its core functions include multi-processor collaboration,communication protocol support and fault diagnosis capabilities,and are widely used in power,energy,automation production lines and other fields.

Core functions and technical parameters

1.Hardware architecture

Processor and storage:

Integrate 3 microprocessors and shared RAM,support multi-task parallel processing,and improve control response speed.

LED indicator:

Onboard 10 LED indicators,flashing in sequence indicates normal operation;

Slow flashing:Indicates error code 1-399;

Quick flash:Indicates error code 400-1023.

2.Communication and Extension

Protocol support:

Compatible with multiple industrial communication protocols(specific protocols are not clearly listed,but emphasize”reliable and efficient performance design”).

interface:

Supports serial communication interface,and can download diagnostic data to a laptop for analysis.

3.Troubleshooting and maintenance

Diagnostic tools:

Provide on-board test points(metal columns),and signal paths need to be detected through professional equipment;

The drive’s built-in diagnostic tools are accessible to support performance analysis and error location.

Maintenance requirements:

Testing must be performed by trained personnel,the equipment must be calibrated and complies with safety specifications.

4.Physical specifications

Size and Weight:

Refer to the same series of controller modules,the width is approximately 119 mm(measured along the DIN rail)and the weight is approximately 1.2 kg(including packaging).

Application scenarios

Electricity and Energy:

Control the driving system of gas turbines and power generation equipment to optimize energy efficiency.

Industrial automation:

Manage drive equipment in automated production lines to ensure accurate operation.

Process control:

Coordinate the collaborative work of multiple equipment in metallurgy,chemical industry,water treatment and other industries.

Key Features

High reliability:

Designed for industrial environments,it supports long-term and stable operation,and is suitable for harsh working conditions.

Modular design:

It can be integrated with other GE series modules such as analog input/output modules to extend functionality.

Security:

Built-in protection mechanism reduces the risk of failure and ensures the stability of the control system.