描述

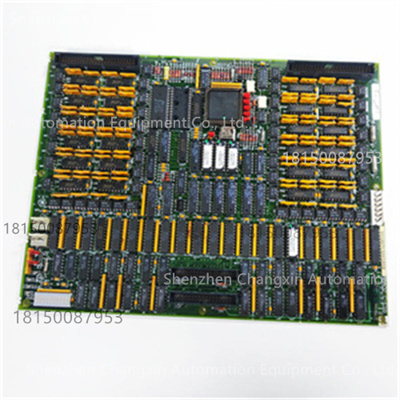

GE DS200TCDAG1BDB是通用电气(GE)专为工业自动化和电力系统设计的数字输入/输出(DI/DO)终端板,属于GE Mark V Speedtronic系列,主要用于燃气轮机、蒸汽轮机等大型旋转设备的控制系统,承担数字信号的转接、分配与电气隔离功能。以下是基于行业资料的综合解析:

一、核心功能与技术特性

数字信号处理与接口

高密度I/O设计:配备2个端子块,支持多路数字信号(如干接点、24V DC逻辑信号)的集中接线,可连接限位开关、继电器线圈、电磁阀等现场设备,兼容Mark V系统的数字输出模块(如DS200DTBC系列),将控制指令转换为强电信号驱动执行器。

电气隔离与抗干扰:采用光电隔离技术(隔离电压≥1500V AC)和金属氧化物压敏电阻(MOVs),有效抑制电磁干扰(EMI)和浪涌冲击,确保信号传输稳定性。

信号调理与保护:部分端子集成过流保护元件(如保险丝),防止外部负载短路损坏核心控制模块,提升系统安全性。

工业级可靠性设计

宽温与防护能力:工作温度范围为-40°C至+70°C,支持IP20防护等级,适应高温、粉尘、振动等恶劣工业环境。

冗余与热插拔:支持双电源输入(24V DC±10%)和热插拔功能,维护时无需停机,模块更换后自动恢复配置,减少停机时间。

故障自诊断:内置状态指示灯(电源、通信、通道故障),可实时监测模块健康状态,支持通过GE Insight工具远程诊断。

系统兼容性与扩展

Mark V系统专属:专为GE Mark V Speedtronic涡轮机控制系统设计,需与Mark V机架(如IC693CHS392H)和背板总线配套使用,兼容Genius协议和冗余控制架构。

灵活配置:通过跳线或拨码开关可调整输入类型(如干接点或24V DC逻辑信号),支持多模块级联扩展,满足复杂工业场景的I/O需求。

二、技术参数概览

项目参数

输入类型数字量:干接点或24V DC逻辑信号

输出类型继电器触点(2A 250V AC)或晶体管输出(24V DC)

通信接口40针JFF连接器(用于核心控制器通信),支持Mark V背板总线协议

处理速度信号更新速率≤5ms(所有通道同步)

电源功耗24V DC,典型功耗150mA

物理尺寸约200mm×100mm×50mm(紧凑型DIN导轨安装)

重量约0.5kg(含连接器)

兼容模块DS200SLCC逻辑控制板、DS200RTB继电器终端板、DS200TCPAG控制处理器

三、典型应用场景

能源与电力行业

燃气轮机控制:采集火焰检测信号、转速探头干接点状态,通过继电器输出控制燃油阀、进气阀的启停逻辑,实现机组安全联锁保护。

蒸汽轮机监测:连接温度开关、压力开关等数字传感器,实时监测蒸汽参数,结合Mark V控制器实现转速闭环控制。

石油化工与冶金

过程自动化:在化工反应釜中,通过数字输入采集液位开关信号,输出控制信号调节泵和搅拌器的启停,实现生产流程自动化。

设备保护回路:转接超温、超压保护信号至紧急停机执行机构,确保危险工况下快速响应。

大型电机控制

配合PLC或DCS系统,控制电机启动器、制动器的继电器线圈,实现电机的远程启停与状态监测,支持Modbus协议与上位机通信。

The GE DS200TCDAG1BDB is a digital input/output(DI/DO)terminal board designed by General Electric(GE)for industrial automation and power systems.It belongs to the GE Mark V Speedtronic series and is primarily used in control systems for large rotating equipment such as gas turbines and steam turbines.It performs digital signal conversion,distribution,and electrical isolation.The following is a comprehensive analysis based on industry data:

I.Core Functions and Technical Features

Digital Signal Processing and Interfaces

High-Density I/O Design:Equipped with two terminal blocks,it supports centralized wiring of multiple digital signals(such as dry contacts and 24V DC logic signals).It can connect field devices such as limit switches,relay coils,and solenoid valves.It is compatible with Mark V system digital output modules(such as the DS200DTBC series),converting control commands into high-powered signals to drive actuators.

Electrical Isolation and Interference Resistance:Utilizing optoelectronic isolation technology(isolation voltage≥1500V AC)and metal oxide varistors(MOVs),it effectively suppresses electromagnetic interference(EMI)and surges,ensuring stable signal transmission.Signal Conditioning and Protection:Some terminals integrate overcurrent protection elements(such as fuses)to prevent external load short-circuits from damaging the core control module,enhancing system safety.

Industrial-Grade Reliability Design

Wide Temperature and Protection:The operating temperature range is-40°C to+70°C,and it supports IP20 protection,making it suitable for harsh industrial environments such as high temperatures,dust,and vibration.

Redundancy and Hot-Swapability:Supports dual power inputs(24V DC±10%)and hot-swap functionality,allowing maintenance without downtime.Module replacement automatically restores the configuration,minimizing downtime.

Fault Self-Diagnostics:Built-in status indicators(power,communication,and channel faults)provide real-time monitoring of module health and support remote diagnostics via the GE Insight tool.

System Compatibility and Expansion

Designed specifically for the GE Mark V Speedtronic turbine control system,it must be used with the Mark V chassis(such as the IC693CHS392H)and backplane bus,and is compatible with the Genius protocol and redundant control architecture.Flexible Configuration:Input types(such as dry contacts or 24V DC logic signals)can be adjusted via jumpers or DIP switches.Multi-module cascading expansion is supported to meet the I/O needs of complex industrial scenarios.

II.Technical Parameter Overview

Item Parameter

Input Type:Digital:Dry contact or 24V DC logic signal

Output Type:Relay contact(2A 250V AC)or transistor output(24V DC)

Communication Interface:40-pin JFF connector(for core controller communication),supports Mark V backplane bus protocol

Processing Speed:Signal update rate≤5ms(all channels synchronized)

Power Consumption:24V DC,typical power consumption 150mA

Physical Dimensions:Approximately 200mm×100mm×50mm(compact DIN rail mount)

Weight:Approximately 0.5kg(including connector)

Compatible Modules:DS200SLCC Logic Control Board,DS200RTB Relay Terminal Board,DS200TCPAG Control Processor

III.Typical Application Scenarios

Energy and Power Industry

Gas turbine control:Collects flame detection signals and speed probe dry contact status,and controls the start and stop logic of fuel and air inlet valves through relay outputs,implementing unit safety interlock protection.Steam Turbine Monitoring:Connect digital sensors such as temperature switches and pressure switches to monitor steam parameters in real time,and combine with the Mark V controller to achieve closed-loop speed control.

Petrochemical and Metallurgical

Process Automation:In chemical reactors,digital inputs are used to collect liquid level switch signals and output control signals to regulate the start and stop of pumps and agitators,automating production processes.

Equipment Protection Circuit:Transfers over-temperature and over-pressure protection signals to emergency shutdown actuators,ensuring rapid response in hazardous conditions.

Large Motor Control:In conjunction with a PLC or DCS system,this system controls the relay coils of motor starters and brakes,enabling remote motor start/stop and status monitoring.It supports Modbus protocol communication with host computers.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101